In the world of materials, the Black Eva Sheet stands out. It is known for its versatility and durability. Many industries rely on this exceptional material. From crafting to construction, the applications seem endless.

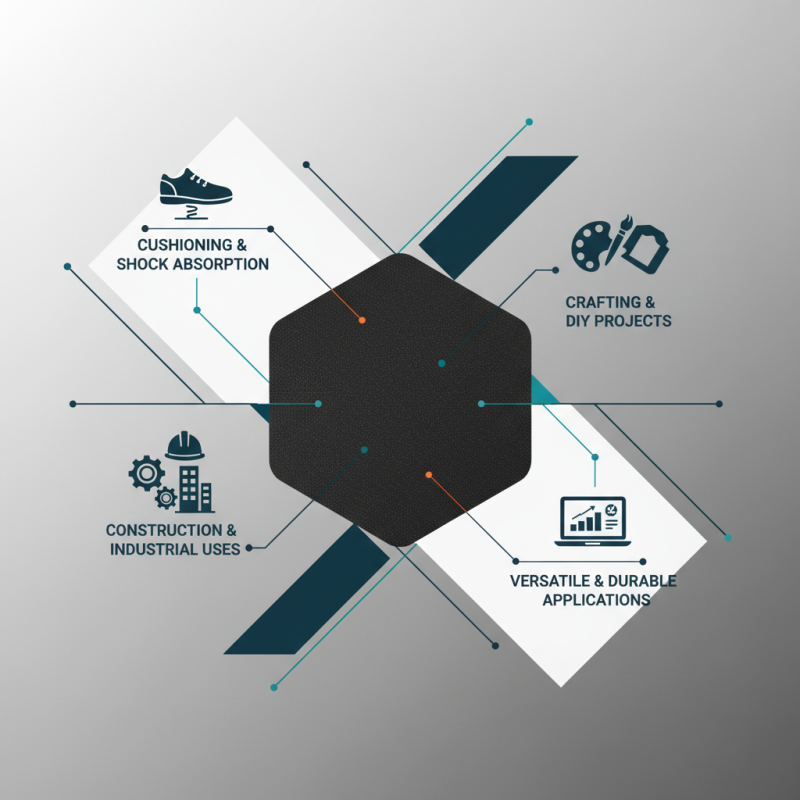

The Black Eva Sheet provides excellent cushioning. It absorbs shock effectively, making it ideal for various uses. However, not all buyers fully understand its potential. This lack of awareness can lead to missed opportunities. Some only see it as a basic material, failing to appreciate its quality.

As we explore the best options for 2026, think about your needs. The right Black Eva Sheet can change the game. Choosing wisely ensures you harness its full benefits. Reflect on the applications in your life and work. You may find new ways to utilize this remarkable material.

Black EVA sheets are becoming increasingly popular. They have a unique combination of versatility and durability. These sheets are made from Ethylene Vinyl Acetate, which gives them rubber-like properties. They can withstand various temperatures and conditions. This makes them suitable for a range of applications.

In construction, black EVA sheets are often used for insulation and shock absorption. Their lightweight nature makes them easy to handle. Moreover, they are waterproof and resistant to UV rays. This extends their lifespan and makes them ideal for outdoor use. Other applications include crafting, packaging, and even flooring. The options are endless.

Tip: When selecting EVA sheets, consider the thickness based on your project needs. Thicker sheets offer better shock absorption. Tip: Always check for flexibility. If the sheet doesn’t bend easily, it might not fit your application well. Remember, not all EVA sheets are the same. It’s crucial to match the right sheet with the intended use to avoid issues later on.

When considering versatile and durable applications, 2026 best black EVA sheets stand out. These sheets provide a unique combination of flexibility and strength. Their lightweight nature makes them easy to handle while maintaining exceptional durability. They can be used in various industries, from packaging to crafting.

Key features of black EVA sheets include excellent water resistance. This property ensures longevity in different environments. Additionally, they offer impressive shock absorption. This is especially beneficial in protective gear. However, some users find that the sheets require careful handling to avoid tearing. It’s important to assess the application requirements closely.

The aesthetically pleasing black color adds a sleek touch to any project. However, it can show dust and grime easily, which may require regular cleaning. Overall, the potential of black EVA sheets is vast, but awareness of their limitations can enhance their effectiveness in diverse applications. Their adaptability makes them a wise choice for those looking to achieve both form and functionality.

| Feature | Description | Benefit |

|---|---|---|

| Durability | Made with high-quality EVA material that resists wear and tear. | Increased lifespan of products, reducing replacement costs. |

| Water Resistance | Repels moisture effectively to prevent damage. | Ideal for outdoor applications and humid environments. |

| Lightweight | Weighs less than traditional materials while providing similar strength. | Easier handling and transportation. |

| Flexibility | Offers excellent flexibility to fit various shapes and designs. | Adaptable for multiple uses across different industries. |

| Color Stability | Maintains rich black color without fading over time. | Enhanced aesthetics for finished products. |

When comparing black EVA sheets for various applications, several features stand out. These sheets are renowned for their durability and versatility. Many are used in industries such as packaging, automotive, and construction. A solid black EVA sheet offers notable resistance to wear and weather conditions. It provides cushioning, which is critical for many products.

However, not all sheets are equal in quality. Some may lack the desired flexibility, while others might be too rigid for certain uses. Thickness can vary significantly between products, affecting overall performance. Users should carefully consider specific requirements for their applications before making a choice.

Additionally, pricing becomes an important factor in this comparative analysis. Certain options may be overpriced for the features they offer. Always assess the trade-offs related to cost versus quality. Products that seem appealing may fall short upon closer inspection. It’s essential to reflect on intended use and environment before committing to a purchase.

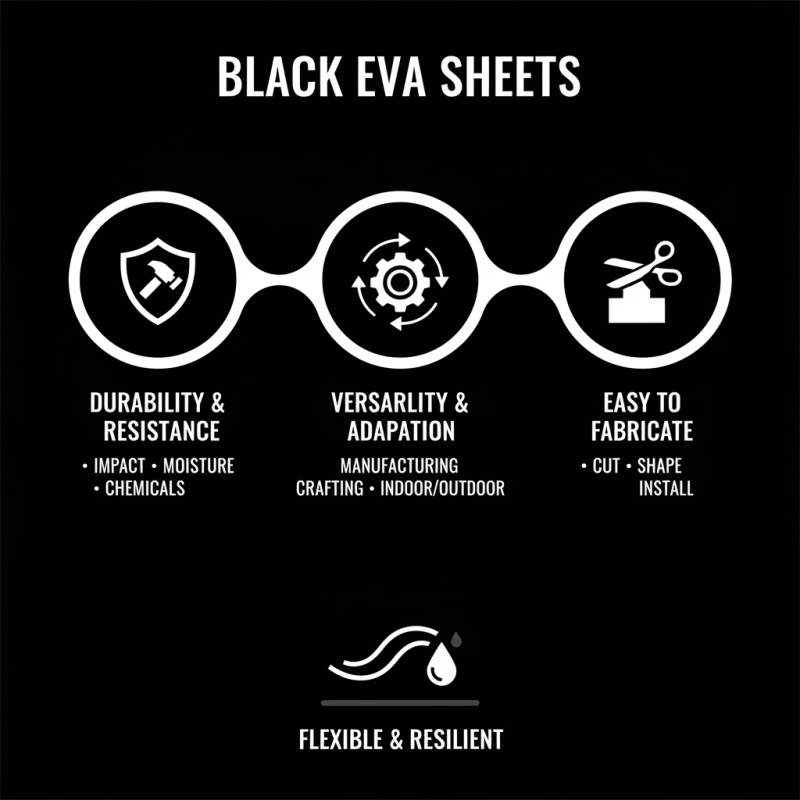

When it comes to selecting the best black EVA sheet, durability and versatility take center stage. These sheets find applications in various environments, from manufacturing to crafting. Their resistance to moisture and chemicals is notable, making them ideal for both indoor and outdoor use. A black EVA sheet can withstand heavy impacts and stress, yet it can be easily cut to fit any design.

However, it's important to acknowledge some limitations. Not all EVA sheets will perform the same under extreme temperatures. While they excel in various conditions, prolonged exposure to intense sunlight can lead to degradation. Users might find that flexibility decreases under harsh climates. It's essential to conduct small tests before committing to large projects.

Additionally, not all uses are as straightforward as they seem. Some applications may require additional treatments for better adhesion or surface finish. Experiments often reveal that inconsistency in density affects performance. Those who miss the finer details may end up disappointed, necessitating closer evaluations. Understanding these factors is crucial for successful utilization in any project.

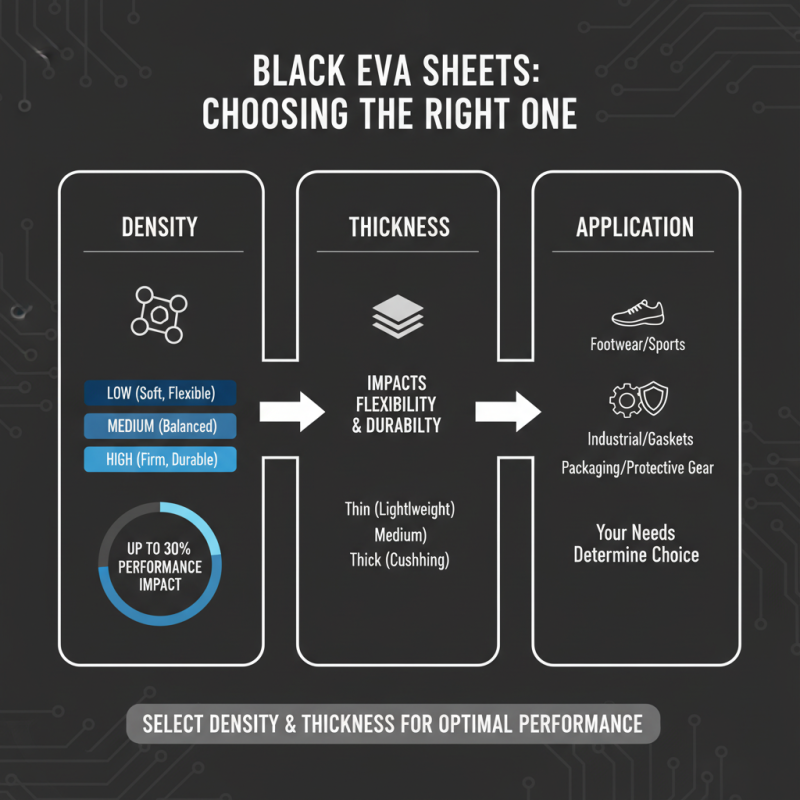

Choosing the right black EVA sheet for your needs requires careful consideration. EVA sheets come in various densities and thicknesses. Each variation affects the final product's flexibility and durability. A recent industry report indicates that density can impact performance by up to 30%. This means picking the right density is crucial for your specific application.

Look for specific properties that matter to you. Are you working on a project that requires waterproof materials? Or do you need sheets that resist UV radiation? Understanding these characteristics helps you narrow down your options. A survey found that 45% of manufacturers prioritize UV resistance in their EVA sheets for outdoor applications. Remember, not every sheet is ideal for every purpose. Quality and performance can vary widely.

Finally, think about the environmental implications of your choice. Many EVA sheets are recyclable, but some aren't. Research shows that nearly 50% of consumers want eco-friendly options when selecting materials. It's also important to consider the manufacturing process. Ask about certifications and standards. This knowledge ensures your choice aligns with your values.