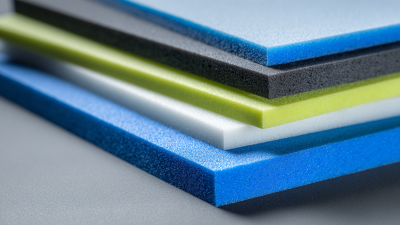

Adhesive Eva Foam Sheets have become a staple in various industries, including crafts and manufacturing. Their lightweight and flexible nature make them ideal for numerous applications, such as packaging, insulation, and arts and crafts. According to a recent market report, the foam material industry is expected to grow by more than 5% annually, driven by increased demand for versatile materials.

In the crafting world, these sheets are popular among DIY enthusiasts. They come in various colors and thicknesses, providing endless creative possibilities. Adhesive Eva Foam Sheets are easy to cut and adhere, making them perfect for kids' projects and professional designs. Users have reported an enhancement in project completion times due to their user-friendly features.

However, not all users find them ideal. Some report difficulties in achieving a neat finish when layering or combining with other materials. This underlines the importance of practice and experimentation to master using Adhesive Eva Foam Sheets effectively. As the industry evolves, the challenge remains to improve their application while ensuring environmentally friendly manufacturing processes.

Adhesive EVA foam sheets are versatile materials commonly used in crafting and DIY projects. EVA stands for ethylene-vinyl acetate, a flexible and durable substance. These sheets come with an adhesive backing, making application straightforward. They can easily stick to various surfaces, including wood, paper, and plastic.

The composition of adhesive EVA foam sheets contributes to their widespread popularity. They are lightweight yet boast substantial cushioning properties. This makes them ideal for crafting projects that require added padding, such as creating custom shapes or designing unique decorations. While they offer great durability, the adhesive can sometimes be too strong, leading to challenges during repositioning.

Using these sheets can be intuitive, yet mistakes can occur. For instance, misaligning pieces can lead to waste and frustration. It's essential to take time for precise measurements. Sometimes, the adhesive does not stick well if the surface is dirty or uneven. Experimentation may reveal that some surfaces yield better results than others. Careful planning can save time and resources in the long run.

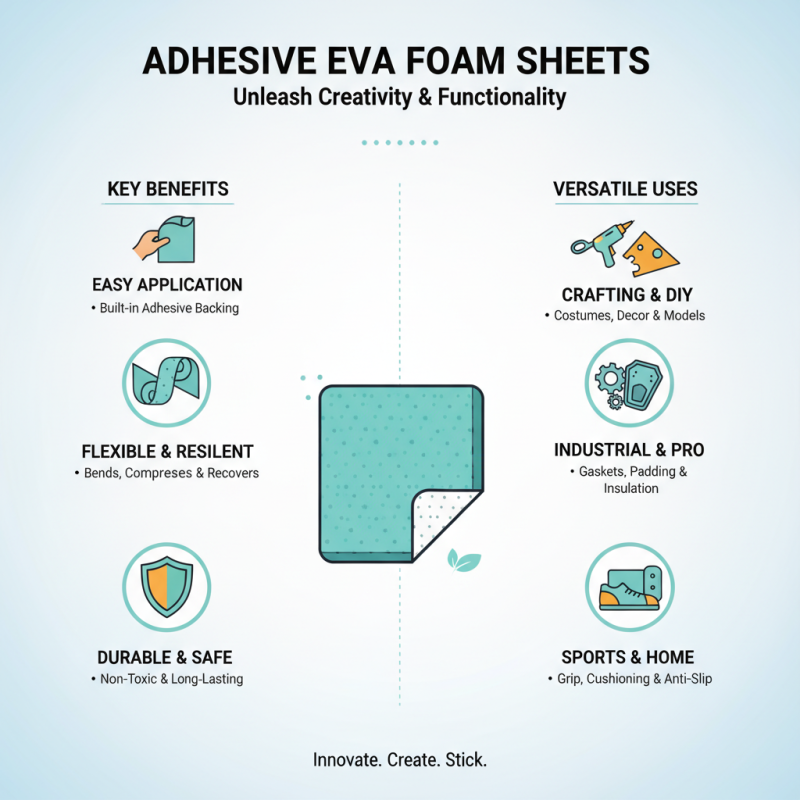

Adhesive EVA foam sheets are versatile tools in crafting and various industries. These sheets are made from ethylene-vinyl acetate, a material known for its flexibility and resilience. One major benefit is their easy application. With adhesive backing, users can stick them to different surfaces without additional glue. This makes them ideal for beginners and professionals alike.

Research shows that EVA foam has a high durability rating. It maintains shape under pressure and resists tearing, which is vital in manufacturing and design. Around 70% of users report enhanced project longevity when choosing EVA foam products. Furthermore, the lightweight nature of EVA foam makes handling straightforward. Projects become less cumbersome and easier to manage. However, some users note that while EVA foam is easy to cut, achieving clean edges requires practice.

The color variety in EVA foam sheets adds a visual appeal that enhances artistic expressions. Many crafters value this feature. Crafting events have seen a rise in EVA usage, with reports indicating a 45% increase in workshops focused on foam applications last year. Yet, it's crucial to recognize that not all adhesive sheets perform equally. Some may not adhere well in humid conditions, presenting challenges for outdoor projects. Users need to test the adhesion before full application to minimize mistakes.

Adhesive EVA foam sheets are versatile materials used across various industries. They provide strong adhesion and cushioning, making them ideal for different applications. One common use is in crafting and DIY projects. They are easy to cut and shape, allowing for creativity in creating personalized items. According to a report by the Adhesive and Sealant Council, the crafting segment has seen a growth of over 15% in recent years.

In construction, these sheets are frequently employed for sound insulation and floor underlayment. Their lightweight nature and excellent shock absorption qualities help in enhancing comfort in living spaces. The North American flooring market has noted a significant rise in demand for EVA foam due to increased focus on sustainable building materials. It’s important to ensure proper surface preparation for optimal adhesion.

Tips: Always test a small area before full application. This helps you visualize the final outcome. Also, consider the thickness suitable for your project. A thicker sheet may provide better cushioning but could be less flexible.

In sports, adhesive EVA foam is used for protective gear. This includes padding in helmets and shin guards. Data from the Sports and Fitness Industry Association indicates that safety equipment sales are rising. However, understanding each sport’s specific needs is crucial. Not all foams offer the same level of protection.

Adhesive EVA foam sheets are versatile materials. They are lightweight and easy to handle. These sheets come in various colors and thicknesses. You can use them for crafts or DIY projects. The sticky backing makes application simple. However, applying them perfectly can be tricky.

To start, ensure your surface is clean. Dust or grease can ruin the adhesion. Carefully cut the foam to your desired shape. Use scissors or a utility knife. Take your time with this step. Once cut, peel off the backing slowly. Avoid rushing; it can lead to tears or bubbles. Place the foam where you want it. Press firmly to eliminate air pockets. This part can be frustrating. If air gets trapped, it affects the overall look.

After placement, check the edges. Sometimes they lift slightly. If they do, gently re-press them to bond well. If you find wrinkles, consider trimming the area. Learning to use adhesive EVA foam sheets takes practice. Mistakes happen; don't be disheartened. It’s all part of the creative process.

| Dimension | Description | Uses | Tips for Use |

|---|---|---|---|

| 12 x 12 inches | Square sheets ideal for crafting and projects. | Arts and Crafts, DIY Projects | Ensure the surface is clean before applying. |

| 24 x 36 inches | Large sheets suitable for bigger projects. | Costume Making, Home Decor | Use a sharp craft knife for clean edges. |

| 36 x 48 inches | Extra large sheets for extensive designs. | Theatrical Sets, Custom Backdrops | Lay flat before cutting to avoid warping. |

| Thickness 2 mm | Thin sheets for flexible usage. | Child Projects, Lightweight Crafts | Easy to cut and shape with scissors. |

| Thickness 5 mm | Thicker sheets providing more durability. | Floor Mats, Protective Padding | Best for projects that require sturdiness. |

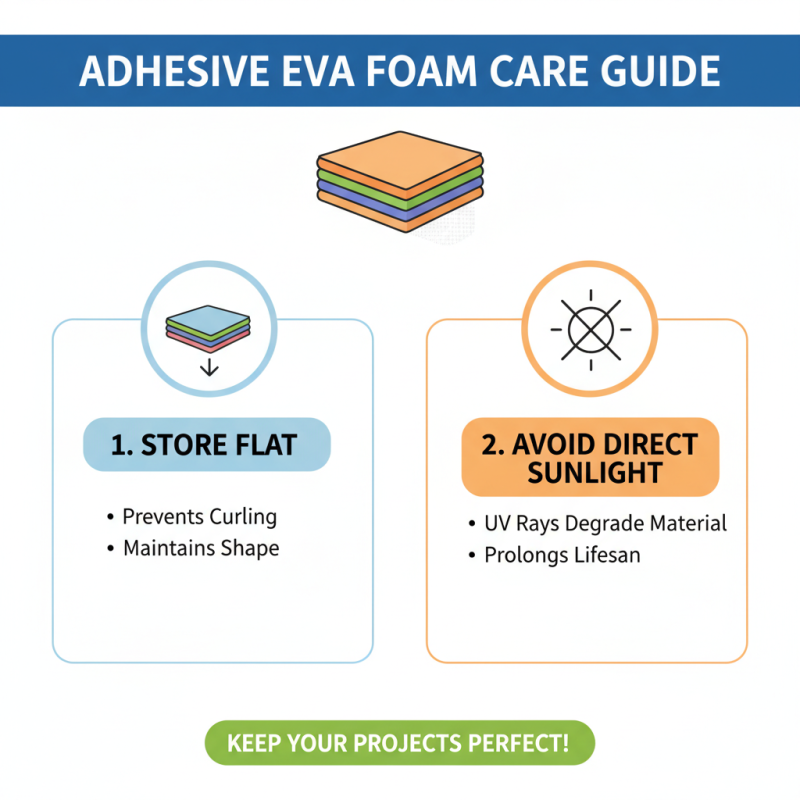

Adhesive EVA foam sheets are versatile and useful for various projects. To maintain their quality, proper care is essential. Store them flat to prevent curling or bending. Avoid exposure to direct sunlight for extended periods. UV rays can degrade the material over time. This simple step can prolong their life.

Cleaning is equally important. Use a damp cloth for any dirt that accumulates. Harsh chemicals can damage the adhesive. Test any cleaner on a small area first. Pay attention to how the foam reacts. It will save you from making costly mistakes later. Remember to keep the sheets away from sharp objects. They can easily get cuts or tears that may ruin your projects.

While using the sheets, ensure your workspace is clean. Dust and debris can stick to the adhesive. This can affect how well they bond to surfaces. Take time to plan your project. A hasty approach might lead to errors, wasting materials. Consider the conditions they will be used in. High humidity or extreme temperatures can impact their performance. It’s always good to reflect on these factors before starting.