In today's competitive manufacturing landscape, the choice of materials plays a crucial role in ensuring product quality and efficiency.

Adhesive Eva Foam Sheets have emerged as a popular solution across various industries,

praised for their versatility and ease of use. According to a recent market analysis by ResearchAndMarkets,

the global EVA foam market is projected to reach USD 4.9 billion by 2027, driven by increasing

demand for lightweight and durable materials in automotive, footwear, and packaging sectors. These sheets not only provide excellent cushioning

and insulation properties but also streamline production processes with their self-adhesive backing, reducing assembly time and labor costs.

As manufacturers seek innovative ways to enhance productivity while maintaining product integrity, incorporating

Adhesive Eva Foam Sheets into their processes presents an opportunity to leverage both

operational efficiency and superior performance.

In today's competitive manufacturing landscape, the choice of materials plays a crucial role in ensuring product quality and efficiency.

Adhesive Eva Foam Sheets have emerged as a popular solution across various industries,

praised for their versatility and ease of use. According to a recent market analysis by ResearchAndMarkets,

the global EVA foam market is projected to reach USD 4.9 billion by 2027, driven by increasing

demand for lightweight and durable materials in automotive, footwear, and packaging sectors. These sheets not only provide excellent cushioning

and insulation properties but also streamline production processes with their self-adhesive backing, reducing assembly time and labor costs.

As manufacturers seek innovative ways to enhance productivity while maintaining product integrity, incorporating

Adhesive Eva Foam Sheets into their processes presents an opportunity to leverage both

operational efficiency and superior performance.

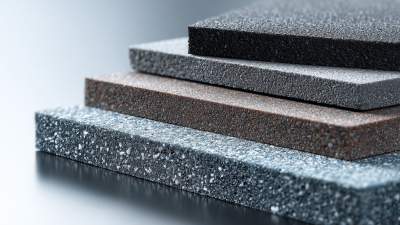

Adhesive EVA foam sheets have gained significant attention in the manufacturing sector due to their unique properties that surpass traditional materials. Unlike conventional substrates such as rubber or cardboard, EVA foam offers excellent resilience and flexibility, making it suitable for various applications ranging from packaging to automotive interiors. According to a recent report by MarketsandMarkets, the global market for EVA foam is projected to reach USD 5.6 billion by 2026, driven by its lightweight nature and superior shock-absorbing capabilities.

One of the standout advantages of adhesive EVA foam sheets is their ease of application. The built-in adhesive eliminates the need for additional bonding processes, resulting in reduced labor costs and increased production efficiency. A study by Grand View Research highlighted that companies using adhesive EVA foam experienced a 15% reduction in production time compared to those relying on traditional adhesives. This time-saving aspect, combined with its excellent acoustic and thermal insulation properties, positions adhesive EVA foam as a formidable alternative that enhances product longevity and customer satisfaction in diverse manufacturing environments.

This chart illustrates the key advantages of using adhesive EVA foam sheets compared to traditional materials. The ratings reflect a scale from 1 to 10, with 10 being the highest advantage. As shown, adhesive EVA foam sheets excel in being lightweight and durable, making them a preferred choice in many manufacturing processes.

Adhesive EVA foam has gained traction in the manufacturing industry, primarily due to its remarkable ability to enhance product durability. The unique properties of EVA foam allow for excellent adhesion and flexibility, making it an ideal choice for various applications. This versatility means that products manufactured using adhesive EVA foam can better withstand environmental stressors, such as temperature fluctuations and physical impacts, which is pivotal in ensuring long-lasting performance and quality.

Recent advancements in adhesive technologies have further solidified the benefits of EVA foam in manufacturing processes. For instance, modifications in thermoplastic polyurethane have shown promising results in improving bonding performance, aligning with the demand for durable and reliable materials. Additionally, the ongoing expansion of the ethylene vinyl acetate market indicates a growing recognition of its applications in diverse sectors. With industries increasingly prioritizing sustainability, the use of adhesive EVA foam also reflects a shift towards more environmentally friendly manufacturing practices, proving that durability and eco-responsibility can indeed go hand in hand.

In today's competitive manufacturing landscape, choosing the right materials is crucial for optimizing costs while maintaining quality. Adhesive EVA foam sheets have emerged as a cost-effective alternative to traditional materials such as rubber and polyurethane. According to a recent report by ResearchAndMarkets, the global EVA market is projected to grow significantly, driven by the increasing adoption of EVA foam in various industries, including automotive and consumer goods. The competitive pricing of EVA foam sheets, which often ranges from 10% to 30% lower than its counterparts, provides manufacturers with a substantial opportunity to reduce production costs without sacrificing performance.

Moreover, the versatility of adhesive EVA foam sheets contributes to their cost-effectiveness. These sheets can be used in multiple applications, from cushioning and insulation to bonding and sealing, effectively reducing the need for additional materials. A study by Smithers Pira highlights that manufacturers can save up to 20% on material costs by implementing EVA foam solutions in their production processes. This adaptability not only streamlines inventory management but also enhances product development timelines, allowing businesses to respond more swiftly to market demands and trends.

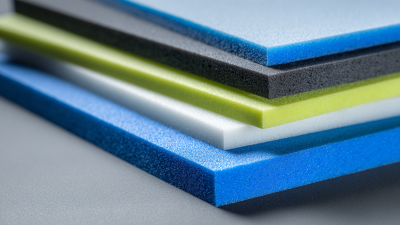

Adhesive EVA foam sheets have become increasingly popular in various manufacturing sectors due to their remarkable flexibility and versatility. As the global flexible foam market is projected to grow from USD 47.96 billion in 2025 to an impressive USD 75.30 billion by 2033, it's clear that businesses are recognizing the potential of materials like EVA foam. This unique foam exhibits excellent cushioning properties, making it suitable for applications ranging from packaging to automotive interiors. Its ability to conform to different shapes without losing its structural integrity provides manufacturers with endless design possibilities.

When considering adhesive EVA foam, it's essential to understand its applications across diverse industries. For example, in construction, adhesive EVA foam is utilized for sound insulation and thermal regulation. In consumer goods, it serves as padding in sports equipment and footwear. The ease of use and effective bonding properties of these foam sheets significantly enhance production efficiency and product performance.

Tip: Always evaluate the thickness and density of EVA foam for your specific application to ensure optimal performance. Additionally, consider color and texture options to meet aesthetic requirements in your final product design.

EVA foam sheets are increasingly recognized as a sustainable choice in manufacturing processes, largely due to their environmental benefits. A report by the Flexible Packaging Association highlights that EVA foam is recyclable and can be reused in various applications, drastically reducing landfill waste. Furthermore, the production of EVA foam typically consumes less energy compared to traditional materials, which aligns with global efforts to minimize carbon footprints. Choosing EVA foam means selecting a material that not only meets functional needs but also supports environmental stewardship.

Tips: When sourcing EVA foam, look for suppliers that provide eco-friendly certifications, ensuring that the materials are produced with sustainable practices in mind. Furthermore, consider purchasing EVA sheets in bulk; this not only reduces packaging waste but also minimizes transportation emissions.

The sustainability of EVA foam does not stop at its production; the material itself is known for its durability and longevity. According to data from the American Chemistry Council, products made from EVA foams can last longer, thus reducing the frequency of replacement and further contributing to sustainability. By investing in high-quality EVA sheets, manufacturers can optimize their processes while adhering to eco-conscious principles.

Tips: Explore options for local sourcing to reduce transportation impact. Additionally, integrating EVA foam waste back into your production can enhance sustainability efforts and cut costs.

| Dimension | Advantages | Environmental Impact | Applications |

|---|---|---|---|

| Thickness | Provides cushioning and shock absorption | Made from non-toxic materials, safe for the environment | Packaging, automotive, and flooring |

| Density | Lightweight yet sturdy, reduces overall material usage | 100% recyclable, minimizes landfill impact | Sporting goods, toys, and crafts |

| Adhesive Properties | Self-adhesive backing for easy application | Low VOC emissions, improves air quality | Insulation, soundproofing, and construction |

| Color Options | Available in various colors for aesthetic choices | No harmful dyes, eco-friendly production processes | Interior design, craft projects, and educational tools |