In the ever-evolving landscape of modern manufacturing, the quest for innovative materials that enhance efficiency and performance is paramount. One such material that has gained significant traction is the PE EVA Foam Sheet. This versatile foam offers a unique combination of lightweight properties, durability, and a vast array of applications, making it an ideal choice for various industries. Whether used in packaging, insulation, or as cushioning material, the benefits of PE EVA Foam Sheets are immense. In this comprehensive guide, we will delve into the characteristics, advantages, and practical applications of PE EVA Foam Sheets, equipping manufacturers with the knowledge to unlock their full potential and gain a competitive edge in the marketplace. Join us as we explore how this material can transform manufacturing processes and bolster product innovation.

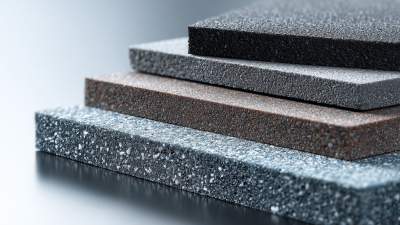

PE EVA foam, a blend of polyethylene (PE) and ethylene-vinyl acetate (EVA), is increasingly recognized for its versatility in modern manufacturing. This material is lightweight, flexible, and provides excellent cushioning, making it ideal for applications in packaging, automotive interiors, and footwear. According to a report from Freedonia Group, the demand for foam materials, particularly PE EVA, is expected to rise significantly, reaching a market value of over $30 billion by 2026. The foam's resilience and durability under various conditions enhance its utility across multiple industries.

**Tip**: When selecting PE EVA foam sheets, consider the specific density of the foam, as higher density options tend to provide better impact resistance and longevity, which is crucial for high-performance applications.

Furthermore, the composition of PE EVA foam allows for customization in properties like hardness and thermal insulation. This adaptability enables manufacturers to tailor the foam for specific requirements, which has been corroborated by a study from MarketsandMarkets indicating that customized foam solutions are gaining traction for their efficiency and sustainability in production processes.

**Tip**: Always test a small sample of the foam in your intended application to determine the best fit, ensuring that you meet performance standards without unnecessary waste.

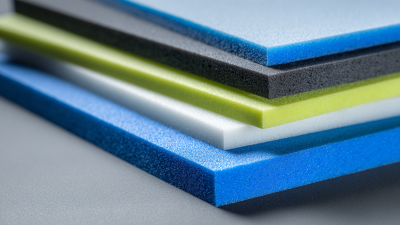

PE EVA foam sheets have gained significant traction in modern manufacturing due to their unique properties that cater to a variety of applications. One of the standout features of these sheets is their lightweight nature, which can reduce shipping costs and make them easier to handle. According to industry reports, the global foam market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030, highlighting the increasing demand for versatile materials like PE EVA.

Another key property of PE EVA foam sheets is their remarkable cushioning and shock absorption capabilities. This makes them ideal for packaging sensitive products, ensuring that items arrive safely without damage. A report by MarketsandMarkets indicates that the packaging segment is expected to drive substantial growth in the foam industry, with an estimated market value of USD 120 billion by 2025.

**Tips:** When selecting PE EVA foam sheets, consider their density and thickness to match your specific application needs. Also, exploring different colors and customization options can enhance branding opportunities for your products. Always source from reputable suppliers to ensure high-quality materials that meet industry standards.

| Property | Description | Benefits |

|---|---|---|

| Density | Varies between 25 to 250 kg/m³ | Lightweight options available for ease of use |

| Compression Resistance | Excellent compressive strength | Durability under load; ideal for impact absorption |

| Thermal Insulation | Low thermal conductivity | Energy saving; reduces heat transfer |

| Moisture Resistance | Waterproof properties | Prevents mold growth; suitable for damp environments |

| Chemical Resistance | Resistant to acids, bases, and oils | Ideal for various industrial applications |

| Flexibility | High elasticity and bendability | Conforms easily to different shapes; enhances design possibilities |

PE EVA foam sheets have emerged as integral materials across a multitude of industries, thanks to their remarkable versatility and performance characteristics. According to a report by Grand View Research, the global EVA foam market is projected to reach $8.71 billion by 2025, with a significant portion attributed to its applications in automotive, construction, and consumer goods sectors. The lightweight yet durable nature of PE EVA foam makes it an ideal choice for insulation and cushioning, especially in automotive interiors where reducing weight can enhance fuel efficiency.

PE EVA foam sheets have emerged as integral materials across a multitude of industries, thanks to their remarkable versatility and performance characteristics. According to a report by Grand View Research, the global EVA foam market is projected to reach $8.71 billion by 2025, with a significant portion attributed to its applications in automotive, construction, and consumer goods sectors. The lightweight yet durable nature of PE EVA foam makes it an ideal choice for insulation and cushioning, especially in automotive interiors where reducing weight can enhance fuel efficiency.

The sports and leisure industry also benefits from PE EVA foam, with applications ranging from yoga mats to protective gear. A survey conducted by Research and Markets indicates that the demand for EVA foam in the sports sector is expected to grow by 5.7% annually. This growth is driven by the increasing consumer awareness regarding health and fitness, further propelling manufacturers to innovate with foam materials that offer both comfort and safety. Additionally, the packaging industry is turning to PE EVA foam for its shock-absorbing properties, ensuring that fragile goods are protected during transit.

As industries continue to evolve, the adaptability of PE EVA foam sheets underscores their critical role in modern manufacturing solutions.

Polyethylene (PE) and Ethylene-Vinyl Acetate (EVA) foam sheets are becoming increasingly essential in modern manufacturing, particularly due to their sustainability and environmental benefits. According to a report from Smithers Pira, the global demand for eco-friendly packaging materials, including foams, is expected to reach $300 billion by 2025. This trend aligns with manufacturers’ efforts to minimize their carbon footprint and utilize more sustainable resources in production processes. PE EVA foam sheets are lightweight, durable, and recyclable, making them a practical choice for companies looking to improve their environmental impact.

Tips: When selecting PE EVA foam sheets, consider sourcing from suppliers who emphasize sustainability in their production methods. Look for certifications indicating that the materials are derived from recycled content or produced with minimal environmental impact. Implementing these materials can also enhance product appeal to environmentally conscious consumers.

In addition, the versatility of PE EVA foam sheets means they can be used in a variety of applications, from packaging to insulation, contributing significantly to waste reduction. The International Energy Agency reported that using lightweight materials like PE EVA in manufacturing can lead to a 10-15% reduction in energy consumption. This shift not only benefits the manufacturer but also helps achieve broader sustainability goals within the industry.

When selecting the right PE EVA foam sheets for manufacturing, several key factors must be considered to ensure optimal performance and cost-effectiveness. One of the most crucial aspects is the density of the foam, which directly influences its durability and application suitability. According to a market research report by Grand View Research, the global foam market is projected to reach $80 billion by 2025, indicating a significant demand for high-quality materials. Choosing a foam with the appropriate density can enhance product lifespan and functionality, particularly for tasks requiring impact resistance.

Another factor to consider is the thickness of the foam. Industry benchmarks suggest that thicker foams provide better cushioning and insulation properties, making them ideal for applications in packaging, automotive parts, and sports equipment. A study from Smithers Pira highlights that the packaging segment alone accounts for 40% of the foam market, emphasizing the importance of selecting the right foam specifications to meet industry standards.

**Tips:** When choosing PE EVA foam, always test samples in real-world conditions to gauge performance. Additionally, consider your specific application requirements—whether it's for thermal insulation, shock absorption, or lightweight structure—tailoring your choice to meet these needs can lead to superior results. Lastly, consult with suppliers to understand the material's properties, ensuring that the foam can withstand environmental factors like UV exposure and moisture.