In today's competitive market, businesses are continually seeking innovative packaging solutions that not only protect their products but also enhance brand perception. One such solution gaining prominence is Eva Foam Packaging, known for its lightweight, shock-absorbent, and environmentally friendly properties. According to a recent report by Smithers Pira, the global demand for protective packaging is projected to exceed $47 billion by 2024, with a significant shift towards sustainable options like Eva foam. Notably, the versatility of Eva Foam Packaging makes it suitable for various industries ranging from electronics to pharmaceuticals, offering exceptional cushioning and protection during transit. As businesses increasingly prioritize sustainability and cost-effectiveness, implementing an Ultimate Checklist for Eva Foam Packaging can help streamline operations while meeting consumer demands for quality and environmental responsibility.

EVA foam packaging has emerged as a pivotal solution for businesses seeking to enhance both product protection and brand identity. One of the primary benefits of EVA foam is its exceptional shock-absorbing qualities, which are crucial for safeguarding products during transit. As highlighted in recent analyses of vibration transmission within packaging systems, selecting the right materials like EVA foam can significantly minimize the risk of damage. This focus on vibration characteristics not only contributes to the longevity of the product but also reinforces the brand's commitment to quality.

Moreover, the integration of eco-friendly practices into packaging choices cannot be overlooked. Businesses are increasingly drawn to materials that align with sustainability goals, such as EVA foam, which can be designed to be recyclable or biodegradable. Current regulatory frameworks are evolving to support these initiatives, requiring transparency in recycled content and labeling for packaging materials. As companies prioritize responsible packaging solutions, EVA foam stands out not only for its protective qualities but also for its potential to enhance brand perception among eco-conscious consumers.

As businesses increasingly prioritize sustainability, EVA foam packaging has emerged as a preferred choice within various industries. This eco-friendly material not only offers excellent cushioning properties but also has the potential for recycling and repurposing. Many companies are now seeking suppliers who provide EVA foam products that are produced through sustainable practices. This trend aligns with the broader movement towards reducing waste and carbon footprints, enabling businesses to meet the demands of environmentally conscious consumers while maintaining their operational efficiency.

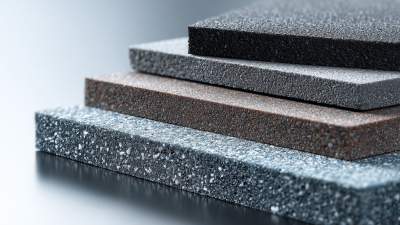

Customization stands out as another pivotal trend in EVA foam packaging. With the evolution of manufacturing technologies, businesses can now create tailored solutions that meet their unique needs. Custom shapes, sizes, and densities allow brands to enhance their product protection while reinforcing their brand identity through distinctive packaging designs. This ability to customize also contributes to improving the user experience, as customers appreciate well-packaged products that reflect attention to detail. As the industry moves forward, the integration of sustainability and customization in EVA foam packaging will likely continue to play a significant role in shaping the future of product packaging.

This chart illustrates the growing trends in EVA foam packaging, particularly focusing on sustainability and customization from 2020 to 2023.

EVA foam packaging is not only an innovative solution but also a financially savvy choice for businesses looking to minimize costs associated with product damage during transit. One of the key advantages of EVA foam lies in its shock-absorbent properties, which significantly reduce the likelihood of breakage and injuries. This resilience translates into lower costs for businesses, as they can avoid expensive replacements and feel confident in their shipping processes.

Moreover, when considering the overall cost analysis, EVA foam packaging proves to be more economical in the long run. By decreasing the frequency of damaged goods, companies can save on refunds, returns, and the labor associated with handling quality control issues. As businesses transition to EVA foam, they may find that investing in superior packaging materials not only safeguards their products but also enhances customer satisfaction, leading to repeat business and better profitability.

| Packaging Type | Damage Rate (%) | Average Repair Cost ($) | Shipping Volume (Units) | Total Damage Cost ($) | Cost Reduction Estimate ($) |

|---|---|---|---|---|---|

| Standard Packaging | 5% | 150 | 1000 | 7500 | 0 |

| EVA Foam Packaging | 1% | 150 | 1000 | 1500 | 6000 |

| Protective Corrugated | 3% | 150 | 1000 | 4500 | 3000 |

| Bubble Wrap | 4% | 150 | 1000 | 6000 | 1500 |

When creating an EVA foam insert for your products, design considerations play a crucial role in ensuring both protection and aesthetic appeal. Begin by accurately measuring your product dimensions to create a custom fit that will securely hold the items in place, preventing movement during transport. This not only enhances safety but also minimizes the risk of damage. Consider the weight distribution of your products, ensuring that the insert is structured to support heavier sections. Utilizing advanced CAD software can further assist in visualizing and refining your design before production, making it easier to identify potential issues.

When creating an EVA foam insert for your products, design considerations play a crucial role in ensuring both protection and aesthetic appeal. Begin by accurately measuring your product dimensions to create a custom fit that will securely hold the items in place, preventing movement during transport. This not only enhances safety but also minimizes the risk of damage. Consider the weight distribution of your products, ensuring that the insert is structured to support heavier sections. Utilizing advanced CAD software can further assist in visualizing and refining your design before production, making it easier to identify potential issues.

Additionally, think about the end-user experience. The foam insert should be easy to remove and replace, making it user-friendly for your customers. Incorporating compartments or cutouts tailored to each product will enhance functionality while showcasing the items effectively. Color and texture are also important; selecting a finish that aligns with your brand identity can create a cohesive look. Ultimately, a well-designed EVA foam insert not only emphasizes product protection but also elevates the overall unboxing experience, leaving a lasting impression on your customers.

EVA foam packaging has garnered attention across various industries due to its unique properties and advantages over traditional materials. Compared to cardboard or plastic, EVA foam offers superior cushioning and shock absorption, making it ideal for fragile items such as electronics or glassware. Its lightweight nature reduces shipping costs, while its durability ensures prolonged protection during transport. A comparative study shows that companies utilizing EVA foam packaging experience fewer damages and lower return rates, highlighting its effectiveness.

EVA foam packaging has garnered attention across various industries due to its unique properties and advantages over traditional materials. Compared to cardboard or plastic, EVA foam offers superior cushioning and shock absorption, making it ideal for fragile items such as electronics or glassware. Its lightweight nature reduces shipping costs, while its durability ensures prolonged protection during transport. A comparative study shows that companies utilizing EVA foam packaging experience fewer damages and lower return rates, highlighting its effectiveness.

When implementing EVA foam packaging in your business, consider these tips: First, assess the specific needs of your products. Different items may require varying levels of protection, so customizing your EVA foam inserts can make a significant difference. Second, explore eco-friendly options. Many EVA foam products are recyclable and can help improve your brand’s sustainability profile. Lastly, conduct regular evaluations of your packaging process to identify areas for improvement and ensure that your packaging methods remain efficient and cost-effective.

As industries evolve, the shift towards EVA foam packaging becomes increasingly relevant. By understanding its comparative advantages and integrating tailored solutions, businesses can enhance their packaging strategies for better customer satisfaction and product protection.