In today's diverse market, the choice of materials can significantly impact product performance and consumer satisfaction, particularly when it comes to EVA foam sheets. According to a report by MarketsandMarkets, the global EVA foam market is expected to reach $4.6 billion by 2026, growing at a CAGR of 6.5%. This surge in demand highlights the material's versatility and widespread applications, from footwear to automotive and sports equipment. Selecting the right EVA foam sheet for your specific needs can be complex, given the various densities, thicknesses, and formulations available.

Understanding the properties and uses of EVA foam sheets not only enhances product design but also ensures compliance with industry standards. This guide aims to demystify the selection process, offering insights into how to choose the best EVA foam sheet that aligns with your product requirements, ultimately driving innovation and success in your projects.

When selecting the ideal EVA foam sheet for your product needs, it's crucial to understand the various types available on the market. EVA (ethylene-vinyl acetate) foam can be classified into several categories based on density, color, and application. According to a report by Market Research Future, the global EVA foam market is projected to reach approximately $9 billion by 2025, highlighting its significance across various industries, including footwear, automotive, and packaging.

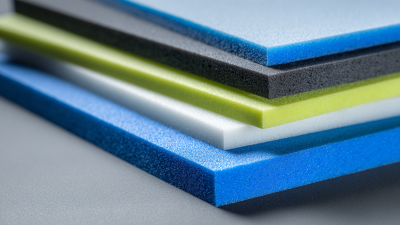

One of the most common types of EVA foam sheets is the cross-linked foam, known for its excellent durability and resistance to water and UV rays. This makes it ideal for outdoor applications and products that require longevity. In contrast, non-cross-linked EVA foam sheets are generally softer and more flexible, making them suitable for applications like crafting and lightweight cushioning. A technical analysis from Smithers Pira indicates that non-cross-linked variants are often favored in consumer product sectors due to their ease of fabrication and lower cost, which can be critical for companies working with tight budgets and fast turnaround times.

Moreover, the color and surface texture of EVA foam sheets can significantly impact their functionality and visual appeal. Custom colors are increasingly in demand, particularly in sectors like children's toys and sports equipment, where aesthetics play a vital role. Recent trends show a growing preference for eco-friendly, recyclable options, as 60% of consumers today prioritize sustainability in their purchasing decisions, according to a study by Nielsen. Understanding these nuances in EVA foam types will empower businesses to make informed choices that align with their product requirements and market expectations.

When selecting the thickness of EVA foam sheets for your product needs, several key factors come into play. The thickness can directly influence the material's durability, flexibility, and overall performance. According to a report by Smithers Pira, the global market for EVA foam is expected to reach $3.2 billion by 2027, highlighting the material’s rising popularity across various industries, from automotive to sports equipment. A thickness of 3-5 mm is often recommended for applications requiring moderate cushioning, while thicker options (up to 10 mm) are ideal for heavy-duty uses, providing significant impact resistance and support.

Additionally, understanding the specific requirements of your application is crucial. For instance, studies indicate that thinner sheets (around 1-3 mm) are highly effective in crafting intricate designs due to their flexibility, making them suitable for crafting and detailed applications. Conversely, for products like floor mats or insulation, thicker sheets can deliver important structural integrity and comfort. A notable survey from Transparency Market Research indicates that over 60% of manufacturers currently prefer 5-8 mm thick EVA foam for versatile applications, balancing comfort and durability efficiently. Thus, considering your product's end use will guide you towards the optimal thickness for your EVA foam sheets.

When selecting EVA foam sheets for your product needs, evaluating their durability and performance is crucial. EVA (ethylene-vinyl acetate) foam is known for its excellent shock absorption, making it ideal for applications ranging from footwear to packaging. Durability is often determined by the density and thickness of the foam; denser sheets tend to withstand wear and tear better, prolonging the life of your product. For high-impact applications, thicker EVA sheets provide the necessary protection and resilience, ensuring the foam can sustain repeated stress without degrading.

In addition to durability, consider the performance characteristics of EVA foam sheets. Factors such as flexibility, temperature resistance, and chemical stability can all influence how the foam behaves in specific environments. For instance, if your product will be exposed to outdoor conditions, it’s essential to choose EVA foam that can endure temperature fluctuations and UV exposure. Moreover, examining the foam's compressive strength will provide insight into how well it can maintain its shape under pressure, ensuring optimal functionality for the intended use. By carefully assessing these aspects, you can select the best EVA foam sheet that meets your performance demands effectively.

When evaluating the cost-effectiveness of custom versus standard EVA foam sheets, it's essential to consider several key factors. According to a report by Smithers Pira, the global EVA market is projected to reach approximately $10.7 billion by 2025, with demand driven by automotive and packaging industries. Custom EVA foam sheets can offer specific densities and formulations tailored to unique product applications, allowing for improved performance characteristics. However, these bespoke solutions often come with a higher price tag, which can be a deterrent for businesses with tight budgets.

In contrast, standard EVA foam sheets typically provide a balance of performance and affordability. A study from Grand View Research highlights that the average cost of standard EVA foam ranges from $2 to $4 per square meter, depending on the thickness and grade. For companies focused on maximizing their profit margins, opting for standard sheets can often yield substantial savings without significantly compromising quality. Ultimately, the decision between custom and standard EVA foam sheets should be guided by a careful assessment of both short-term costs and long-term performance requirements.

When selecting the best EVA foam sheets for specific applications, understanding the unique properties and strengths of EVA (Ethylene Vinyl Acetate) is crucial. Industry reports indicate that the EVA foam market is projected to reach $5 billion by 2025, largely driven by its versatility across various sectors, including automotive, footwear, and packaging.

For instance, in the footwear industry, EVA foam is favored for its lightweight and cushioning properties, making it an excellent choice for insoles and midsoles. Its shock-absorbent characteristics can reduce fatigue and enhance comfort, aligning perfectly with the growing demand for performance-enhancing materials.

For applications in the automotive sector, EVA foam sheets serve critical functions, such as sound proofing and thermal insulation. According to a recent study by Grand View Research, the automotive segment is expected to account for over 30% of the EVA foam market by 2024. When choosing EVA foam for sound insulation, it’s vital to focus on density and thickness; higher density foams often yield better sound-dampening capabilities.

Additionally, for packaging applications, selecting EVA foam with specific hardness levels can significantly protect sensitive products during shipping, showcasing its adaptability to meet distinct performance requirements.