When selecting materials for comfort and durability, "High Density Eva Foam" stands out as a top choice across various industries. Recent studies indicate that high-density EVA foam provides enhanced resilience and longevity, making it a preferred option for products ranging from footwear to cushioning in furniture. According to the Global EVA Foam Market Report, the demand for high-density EVA foam is projected to grow significantly, driven by its superior performance characteristics, such as improved compression resistance and shock absorption. Furthermore, the report highlights that products made from high-density EVA foam exhibit a 20-30% increase in durability compared to their low-density counterparts. As consumers and manufacturers alike prioritize comfort and durability, understanding the selection criteria and benefits of high-density EVA foam becomes crucial for making informed decisions in design and material sourcing.

When selecting high-density EVA foam, there are several key factors to consider to ensure superior comfort and durability. One crucial aspect is the density of the foam itself, as higher density typically indicates better support and longevity. Testing the foam's firmness can also help gauge comfort levels, ensuring it meets your specific needs for activities such as exercising or leisure.

Another important consideration is the intended use of the foam. For instance, if you're looking for foam to be used in sports accessories, such as mats or rollers, ensure the material provides adequate shock absorption and resilience. Additionally, think about any antibacterial properties, which can be beneficial in maintaining hygiene, especially in shared environments.

**Tip:** Always look for foam products that come with warranties, as this can be a good indicator of the manufacturer’s confidence in their durability.

**Tip:** Consider user reviews and expert recommendations to identify those high-density EVA foam products that resonate with comfort and performance standards.

| Factor | Description | Importance Rating (1-5) |

|---|---|---|

| Density | Higher density provides better durability and comfort. | 5 |

| Thickness | Optimal thickness enhances cushioning and support. | 4 |

| Compression Resistance | Resistance to deformation under pressure ensures longevity. | 5 |

| Comfort Level | User subjective comfort assessment is crucial. | 5 |

| Durability | Resistance to wear and tear under regular use. | 5 |

| Moisture Resistance | Prevents decay and odor from moisture retention. | 4 |

| Environmental Safety | Non-toxic and eco-friendly materials are preferred. | 5 |

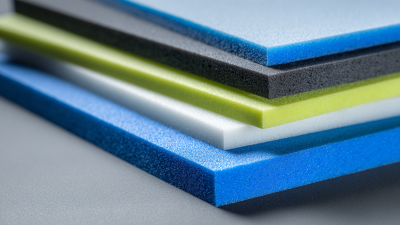

When selecting high-density EVA foam, it's crucial to understand the different grades available, as they directly impact comfort and support. EVA foam, or ethylene-vinyl acetate foam, is categorized based on its density, which affects its resilience and feel. A study by the International Journal of Polymer Science highlights that higher-density EVA foam (typically over 60 kg/m³) significantly enhances durability, making it ideal for products subjected to continuous use, such as yoga mats and athletic footwear.

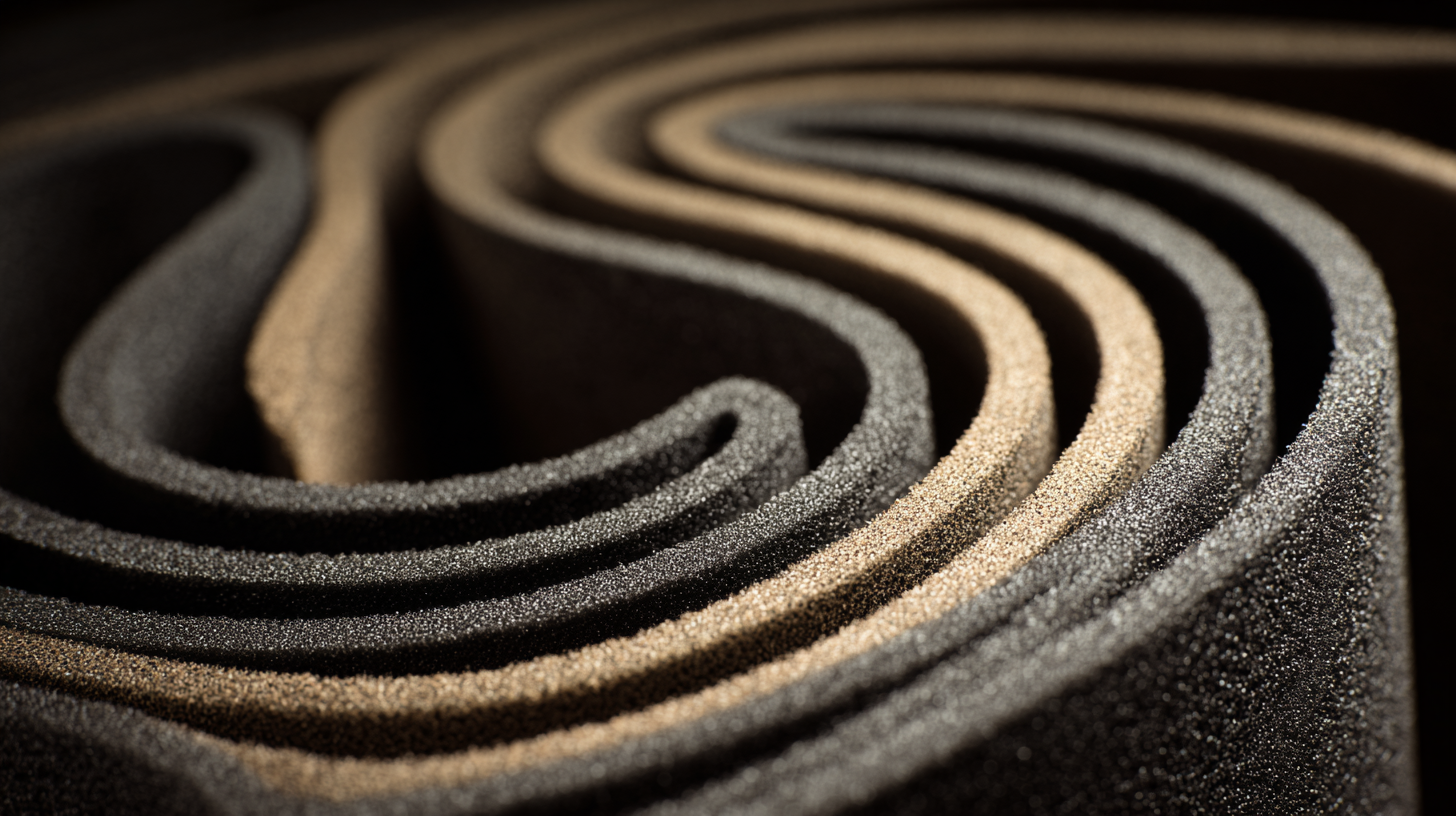

When assessing the durability of EVA foam in various applications, it is essential to consider its mechanical properties and environmental resilience. According to a report by Grand View Research, the global EVA foam market is expected to reach $2.87 billion by 2025, indicating a growing adoption in industries such as footwear, automotive, and sports equipment. EVA foam boasts impressive tensile strength, typically ranging from 15 to 30 MPa, which ensures that it retains its shape and structure under stress, making it suitable for high-impact applications.

Furthermore, EVA foam demonstrates excellent resistance to moisture, UV light, and temperature changes, contributing to its longevity. A study published in the Journal of Applied Polymer Science highlights that the foam can maintain its physical properties even after prolonged exposure to harsh environmental conditions, with less than 5% degradation in tensile strength over five years. This durability makes EVA foam a preferred choice for products that require both comfort and resilience, including yoga mats and protective padding in sports equipment. Collectively, these properties emphasize the importance of choosing high-density EVA foam materials that promise superior comfort and durability for consumers and industries alike.

When it comes to selecting foam materials for various applications, high-density EVA (ethylene-vinyl acetate) foam stands out due to its unique combination of comfort and durability. Compared to traditional polyurethane and polystyrene foams, high-density EVA foam exhibits significantly better resilience and flexibility. According to a report by Freedonia Group, the global demand for EVA foam is projected to increase by 3.9% annually, driven by its superior performance characteristics in sectors such as footwear, sports equipment, and automotive interiors.

One of the key advantages of high-density EVA foam is its ability to absorb impact while maintaining structural integrity, making it ideal for protective gear and flooring solutions. Testing from the American Society for Testing and Materials (ASTM) reveals that high-density EVA foam can endure compression set values as low as 10%, compared to 20% or more found in lower-grade foams. This low compression set indicates that high-density EVA foam can retain its shape and cushioning properties over time, leading to longer-lasting products and enhanced user comfort in applications ranging from yoga mats to ergonomic seating.

When selecting high density EVA foam products, maintenance and care are crucial for ensuring their longevity and performance. Regular cleaning is essential to remove dirt and debris that can accumulate over time. A simple mixture of mild soap and warm water can be used for gentle cleaning. It is advisable to use a soft cloth or sponge, avoiding harsh chemicals and abrasive materials that could damage the foam surface.

In addition to regular cleaning, proper storage plays a significant role in maintaining the integrity of high density EVA foam. Store your products in a cool, dry place away from direct sunlight, which can cause the material to break down. If the items will not be used for an extended period, consider covering them with a breathable fabric to prevent dust accumulation. Also, avoid compressing or stacking heavy items atop the foam to maintain its shape and cushioning properties. By following these simple maintenance tips, you can ensure that your high density EVA foam products remain comfortable and durable for years to come.