In recent years, the demand for Black Eva Foam Sheets Roll has surged across various industries, including packaging, automotive, and construction. According to a report by ResearchAndMarkets, the global EVA foam market is projected to grow significantly, reaching a value of approximately $12 billion by 2025, driven by its lightweight, durable, and water-resistant properties. Choosing the right Black Eva Foam Sheets Roll for your project is crucial to ensure optimal performance and efficiency. With a plethora of options available, understanding the specific types, thicknesses, and densities of EVA foam can significantly impact the success of your applications, whether for cushioning, insulation, or creative crafting. This guide will provide you with essential insights and practical tips to make informed decisions tailored to your unique project requirements.

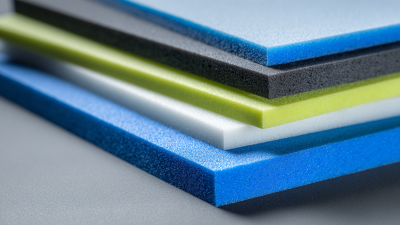

When selecting black EVA foam sheets for your project, it's essential to understand the different types available on the market. EVA foam comes in various densities and thicknesses, which can significantly impact its suitability for different applications. For instance, a high-density EVA foam sheet is ideal for crafting durable products like padding or protective gear, while lower-density options may be more appropriate for lightweight projects, such as costume design or simple craft applications.

Moreover, EVA foam sheets also differ in texture and resilience. Some sheets feature a smooth surface, perfect for painting or printing, while others may have a textured finish that enhances grip or adds a decorative element. The choice between closed-cell and open-cell foam can also affect your project's outcome; closed-cell foam is water-resistant and often used in marine applications, while open-cell foam provides better sound absorption for soundproofing purposes. Understanding these differences will help you choose the right black EVA foam sheet that meets your project's specific needs.

When selecting the right black Eva foam sheets roll for your project, it is essential to consider several key factors that align with your specific application. First and foremost, the density of the foam plays a crucial role in determining its durability and performance. Higher density sheets are typically more resilient and better suited for applications that require impact resistance, while lower density options may be appropriate for lighter tasks or temporary use.

Another important factor is the thickness of the foam sheets. Depending on your project needs, you may require thicker sheets for cushioning or insulation, or thinner sheets for flexibility and ease of handling. Additionally, consider the texture and surface finish of the foam. A smooth surface may be preferable for aesthetics or easier cleaning, while a textured surface could provide better grip or sound dampening properties. Lastly, evaluate the availability of the sheets in specific sizes and rolls to ensure they fit your project requirements without excessive waste.

This bar chart compares key factors considered when selecting black Eva foam sheets for different applications including insulation, cushioning, and craftsmanship.

When selecting black EVA foam sheets for your project, understanding industry standards and certifications is crucial to ensure the quality and safety of the materials you are using. High-quality EVA foam should comply with established standards that typically focus on non-toxicity, durability, and performance. Certifications such as ASTM and ISO indicate that the foam meets specific testing requirements, offering assurance that it is safe for various applications, including crafting, manufacturing, and packaging.

Moreover, sustainability is becoming increasingly important in material selection. Many manufacturers are now adopting eco-friendly practices, producing EVA foam from recycled materials. This aligns with the broader trend seen in various industries, such as the footwear sector, where brands are making strides towards environmental responsibility. When evaluating foam sheets, look for brands that emphasize sustainable sourcing and production methods, as these not only adhere to quality standards but also contribute to a cleaner planet. Prioritizing both performance and sustainability will elevate your project while supporting responsible practices within the industry.

| Dimension | Density (kg/m³) | Thickness (mm) | Hardness (Shore) | Certifications |

|---|---|---|---|---|

| 100 x 200 cm | 30 | 5 | 35 | ISO 9001 |

| 150 x 300 cm | 40 | 10 | 45 | REACH |

| 200 x 400 cm | 50 | 8 | 50 | OSHA |

| 120 x 240 cm | 33 | 6 | 40 | CE |

When selecting black EVA foam sheets for your project, it's crucial to evaluate the relationship between cost and quality. While it may be tempting to opt for the cheapest option available, doing so can lead to compromises in durability and performance. High-quality EVA foam typically offers better resilience, flexibility, and longevity, which can ultimately save you money in the long run by reducing the need for replacements.

Tips for ensuring you choose the right balance include comparing the specifications of different products. Look for sheets that have a higher density, as these tend to be more robust and capable of withstanding wear and tear. Additionally, consider the thickness of the foam; thicker sheets may cost more upfront but provide superior cushioning and insulation, enhancing your project's overall effectiveness.

Don’t forget to read customer reviews to understand how the foam performs in real-world applications. Consistent feedback about quality can help steer you toward products that deliver on their promises. Ultimately, investing time in research will contribute to a more satisfactory and cost-effective choice for your project.

Black EVA foam sheets are versatile materials widely used across various industries due to their excellent cushioning properties, durability, and lightweight nature. In the automotive industry, for example, these sheets are often utilized for sound insulation, providing a quieter cabin experience by absorbing vibrations and reducing noise levels. Additionally, black EVA foam is commonly used in the manufacturing of floor mats and padding, enhancing comfort and safety while providing an attractive aesthetic element.

In the sporting goods sector, black EVA foam sheets serve critical functions in equipment, footwear, and protective gear. Their shock-absorbing capabilities make them ideal for providing support and protection for athletes during intense physical activities. Furthermore, the packaging industry frequently employs these foam sheets as protective inserts, ensuring that fragile items remain secure during shipping. Overall, the versatility of black EVA foam sheets allows them to meet the specific needs of diverse applications, making them an indispensable material for many professionals.