In the world of project materials, the choice of the right EVA Board Sheet can significantly influence the success of your endeavors. As industry expert Dr. Jane Holloway, an experienced materials scientist, aptly states, "Selecting the appropriate EVA Board Sheet not only enhances the durability of your project but also optimizes its functionality." The versatility and lightweight nature of EVA Board Sheets make them a popular choice across various applications, from packaging solutions to artistic installations.

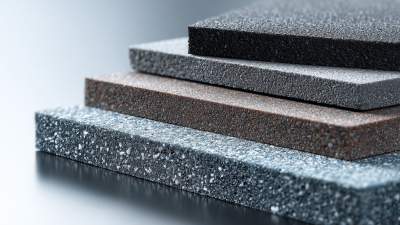

When embarking on a new project, understanding the specific properties and applications of EVA Board Sheets is crucial. Factors such as thickness, density, and color can affect not only the aesthetic appeal but also the performance and durability of the final product. By carefully assessing your project requirements and consulting with experts like Dr. Holloway, you can make informed decisions that align with your objectives. As the demand for high-quality, adaptable materials continues to grow, mastering the art of selecting the right EVA Board Sheet has never been more important for achieving optimal results.

EVA board sheets, made from ethylene-vinyl acetate, have gained popularity across various industries due to their unique composition and beneficial properties. This thermoplastic material is characterized by its flexibility, durability, and resistance to UV radiation, thereby making it an optimal choice for outdoor applications. The blend of ethylene and vinyl acetate allows for a balance between toughness and elasticity, providing a cushioning effect and excellent impact resistance, which is particularly advantageous for packaging and protective applications.

In addition to its physical properties, EVA board sheets exhibit great chemical stability. They are resistant to many chemicals, including acids and bases, which enhances their usability in environments where exposure to harsh substances is likely. Furthermore, the non-toxic nature of EVA makes it a safer choice for consumer products, ensuring compliance with safety standards. In terms of thermal properties, EVA materials maintain integrity across a range of temperatures, making them suitable for various climates and applications. Understanding these characteristics is crucial when selecting the right EVA board sheet for any project, as it allows for informed decisions that align with the specific requirements of the intended use.

When selecting the right EVA board sheet for your project, understanding the dimensions and thickness is crucial. The thickness of EVA sheets can dramatically influence their performance and durability. Industry standards indicate that EVA sheets typically range from 1mm to 20mm thick, and the choice largely depends on the intended use. For example, sheets used in packaging applications often require a thickness around 2-5mm for optimal flexibility and cushioning, while applications demanding structural support, such as in automotive or construction sectors, may necessitate thicker sheets, upwards of 10mm.

Additionally, dimensions of the EVA board should align with project specifications to minimize waste and maximize efficiency. The most common sizes for EVA sheets in industrial applications are 1200mm x 2400mm and 1000mm x 2000mm. According to a recent report from the International Plastics Association, dimensions that suit standardized manufacturing processes can lead to a 15% reduction in material costs and processing times. Thus, assessing your project's requirements involves not only selecting the appropriate thickness but also choosing dimensions that fit your manufacturing methods, ensuring both effective performance and cost-efficiency.

| Project Type | Recommended Dimensions (inches) | Thickness (mm) | Common Uses |

|---|---|---|---|

| Packaging | 24 x 36 | 2 | Protective cushioning, inserts |

| Sports Mats | 48 x 72 | 5 | Yoga, gym flooring |

| Toys | 12 x 12 | 1 | Soft building blocks, puzzles |

| Insulation | 36 x 48 | 3 | Thermal insulation applications |

| Footwear | 20 x 30 | 4 | Shoe soles, insoles |

When selecting an EVA board sheet for your project, evaluating durability and performance is crucial. The material's strength and resistance to environmental factors can significantly impact its suitability for your specific needs. EVA (Ethylene Vinyl Acetate) is known for its flexibility, cushioning properties, and resistance to UV radiation, making it an excellent choice for various applications. However, not all EVA sheets are created equal; their durability can vary widely based on the manufacturing process and the specific blend of materials used.

Tips: Always check the specifications of the EVA sheets you are considering. Look for sheets that provide detailed information on tensile strength, tear resistance, and how well they withstand extreme temperatures. This information will give you a better idea of how the material will perform in real-world conditions.

Another important aspect to consider is the intended use of the EVA board. For applications exposed to harsh conditions, such as outdoor installations, choosing sheets with enhanced resistance to abrasion and impact is vital. Ensure that the material's properties align with the environmental stresses it will face, which can help prolong its lifespan and maintain performance reliability.

Tips: Conduct a small scale test if possible, this can help you better understand how the material reacts under specific conditions relevant to your project, ensuring that your choice will meet your expectations over time.

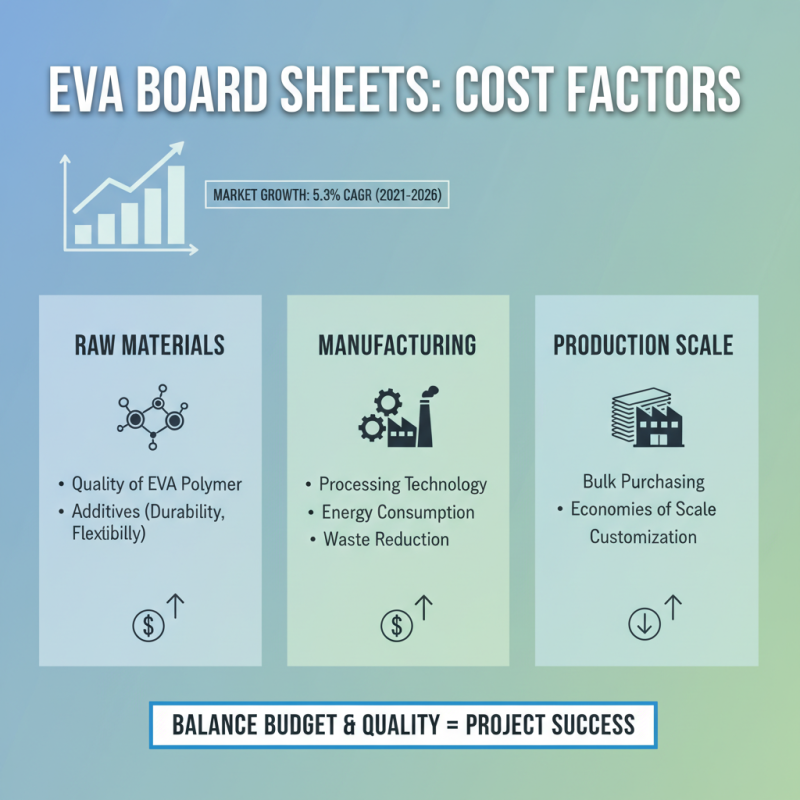

When it comes to selecting the right EVA board sheets for your projects, understanding the cost factors is crucial. According to a recent report by Smithers Pira, the EVA market is expected to grow at a CAGR of 5.3% from 2021 to 2026, indicating a rising demand that directly influences pricing. The primary cost components include the quality of raw materials, manufacturing processes, and the scale of production. Higher quality EVA sheets, which often incorporate advanced additives for enhanced durability and flexibility, generally come at a premium price. Therefore, balancing budget constraints with the necessity for high-quality materials is essential for long-term project success.

Moreover, quantity plays a pivotal role in cost management. Bulk purchasing typically results in significant discounts, which can substantially reduce the per-unit cost. Industry analysis suggests that companies can save anywhere from 10% to 30% on standard EVA sheets when ordering in larger quantities. This is particularly important for projects requiring extensive sheets, such as commercial flooring or insulation materials. By properly assessing the required volume against budget limitations, project managers can make informed decisions that effectively meet both quality standards and financial goals.

When selecting an EVA board sheet supplier, reliability and support services play a crucial role in ensuring the success of your project. According to a report by Grand View Research, the global EVA market was valued at approximately $14.8 billion in 2022 and is expected to exhibit a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. This indicates a growing demand for high-quality EVA materials, making it essential to partner with suppliers who not only provide superior products but also an effective support system.

Assessing a supplier’s reputation involves examining their industry experience, customer testimonials, and their ability to deliver on time. A comprehensive review of a supplier’s quality assurance practices can help gauge their commitment to maintaining high product standards. Furthermore, reliable suppliers often offer additional support services, such as technical assistance, customization options, and proactive communication, which can enhance project outcomes.

According to industry analysts, companies that prioritize strong partnerships with their suppliers report up to 25% higher project efficiency, underscoring the long-term benefits of choosing the right EVA board sheet supplier.