Choosing the right LDPE bag for your packaging needs can be challenging. With various options available, knowing what fits best is crucial. Industry expert Dr. Emily Zhang states, "The right LDPE bag enhances not just product safety, but also sustainability."

Understanding the specific requirements for your items is essential. For example, consider the thickness and size of the LDPE bag. Thin bags may suffice for lightweight products, whereas heavier items require sturdier options.

Often, businesses overlook the impact of their packaging choices. They may stubbornly stick to a single bag type. This leads to inefficiencies that can compromise product integrity. Reflecting on choices made will improve packaging strategies and overall outcomes.

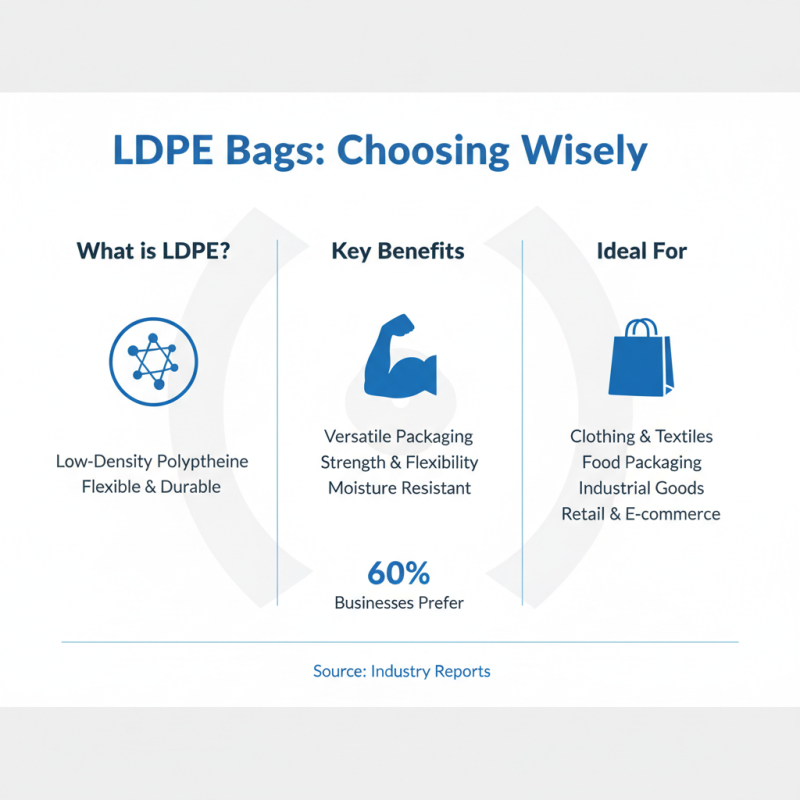

LDPE bags offer a unique blend of flexibility and durability, making them a popular choice in packaging. These bags are made from low-density polyethylene, a material that is both lightweight and strong. This combination allows LDPE bags to carry various items without tearing easily. They come in a variety of sizes, which makes them suitable for both small and large products.

The benefits of LDPE bags extend beyond their physical properties. They are resistant to moisture and chemicals, ensuring the contents inside remain protected. This feature is particularly useful for food packaging or storing sensitive items. However, one must reflect on the environmental impact. While LDPE bags can be recycled in some areas, they often contribute to pollution if not disposed of properly. Finding eco-friendly alternatives remains a challenge for many businesses.

When choosing LDPE bags, consider the intended use carefully. Assess the weight and type of products you will package. It's crucial to choose a bag that meets those specific needs. Some may overlook the importance of bag thickness or size. Ignoring these details could lead to unwanted damage to products or additional costs.

When selecting an LDPE bag, it's crucial to identify your specific packaging needs and objectives. LDPE, or low-density polyethylene, offers versatility. According to industry reports, approximately 60% of businesses prefer LDPE bags for their strength and flexibility. This makes them ideal for a variety of products, from clothing to food packaging.

Understanding the weight and volume of the items you plan to package can guide your choice. LDPE bags are available in varying thicknesses, measured in microns. A heavier bag is essential for bulkier, heavier items. In contrast, a thinner bag might be sufficient for lighter, less fragile products. It’s notable that a miscalculation in bag thickness can lead to damage or product loss, affecting overall profitability.

Additionally, consider environmental concerns. While LDPE bags are recyclable, not all facilities accept them. Assessing your target market’s recycling habits is important. Many companies face challenges in juggling sustainability and functionality. Striking the right balance is not easy. You may need to rethink your packaging strategies over time. This could lead to improved customer satisfaction and reduced environmental impact.

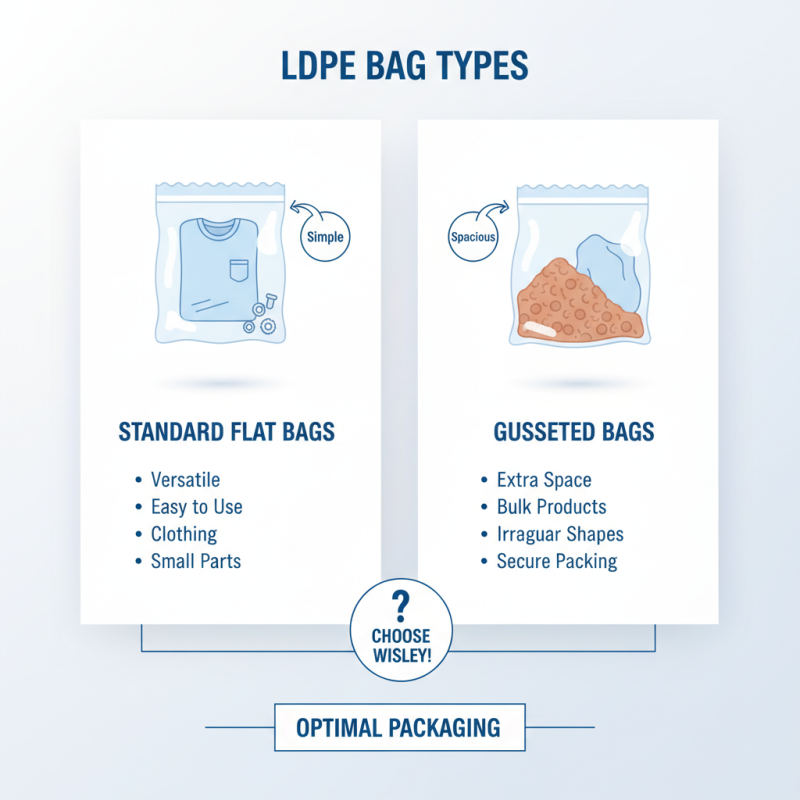

When selecting the right LDPE bag, it’s crucial to consider the various types available. Different styles offer unique benefits for packaging needs. Standard flat bags are versatile and easy to use. They work well for items like clothing and small parts. Conversely, gusseted bags provide extra space, ideal for bulk products or irregular shapes. The added room helps in secure packing.

Another option is the LDPE zip lock bag, favored for its resealability. These bags suit food items or items requiring safe storage. Their ability to maintain freshness is a bonus. However, evaluating your specific requirements is essential. Some may find the thickness of the bag a concern. Thinner bags might not hold up under heavier weights or sharp edges.

It’s also important to reflect on the environmental impact of using plastics. While LDPE is recyclable, the recycling process can be complex. Some users might overlook this responsibility. Understanding the material's lifecycle can improve choices in packaging. Focus on your specific needs and the best LDPE bags for your applications. Mistakes can happen, but learning from them is part of the process.

When considering LDPE bags, one must reflect on their environmental implications. LDPE, or low-density polyethylene, is a type of plastic. While it is often seen as lightweight and versatile, its impact on the environment is significant. The production of LDPE bags involves fossil fuels, which contribute to greenhouse gas emissions. Furthermore, improper disposal can lead to long-lasting pollution in ecosystems.

Recycling LDPE bags poses challenges as well. Many recycling facilities do not accept them due to their nature. Even when they are recycled, the process can be inefficient and energy-intensive. Some consumers may mistakenly believe that recycling will solve environmental concerns. It is essential to weigh the convenience of LDPE bags against their lifecycle impact. Are we truly minimizing our footprint?

Sustainability can also relate to usage. Opting for reusable options may reduce reliance on LDPE. However, it's easy to overlook this in daily practices. The decision-making process around packaging needs improvement. Many individuals do not consider the full environmental consequences of their choices. Engaging in deeper reflection about LDPE can spur more sustainable habits in packaging.

| Bag Type | Thickness (microns) | Recyclability | Environmental Impact | Average Lifespan (Years) |

|---|---|---|---|---|

| Standard LDPE Bag | 50-100 | Yes | Low impact if recycled | 1-3 |

| Heavy Duty LDPE Bag | 150-200 | Yes | Moderate impact; often reused | 3-5 |

| Biodegradable LDPE Bag | 40-80 | Limited | Lower impact but specific conditions required | 1-2 |

| Recyclable LDPE Bag | 70-120 | Yes | Lower impact when recycled | 2-4 |

| Custom Printed LDPE Bag | 50-120 | Yes | Variable; often evaluated by use | 2-3 |

When selecting suppliers for LDPE bags, quality is paramount. It's crucial to evaluate the supplier’s production processes. Look for those who maintain ISO certifications or other quality standards. A 2021 industry report noted that only 30% of suppliers consistently meet quality benchmarks. This inconsistency can lead to significant issues in your packaging.

Understanding material properties is essential. LDPE bags are known for their flexibility and moisture resistance. However, not all LDPE bags share the same quality. Some might contain recycled materials that can compromise strength. A study by the Flexible Packaging Association shows that bags made from virgin resins have a 15% higher tensile strength than recycled alternatives. Make sure to request detailed specifications from your suppliers.

It’s also wise to perform regular quality checks. This can help ensure that batches meet your standards. Customer feedback is invaluable, yet many companies overlook it. A 2023 survey found that 25% of businesses do not respond to quality-related concerns from clients. This gap could lead to supply issues down the line. Facing these challenges head-on can help enhance your packaging solutions.