Choosing the right Eva Rubber can significantly impact the success of various projects. According to a recent industry report by Smith & Associates, the global demand for Eva Rubber has increased by 12% over the past year. This growth stems from its versatility in markets like packaging, footwear, and automotive applications.

Industry expert Dr. Emily Chen states, “Selecting the best Eva Rubber requires an understanding of material properties and project requirements.” Her insight emphasizes the need to consider factors like durability, flexibility, and cushioning. However, many project managers overlook these criteria, leading to suboptimal performance.

When sourcing Eva Rubber, it’s crucial to evaluate supplier credentials and product specifications. Not all Eva Rubber types are created equal. Some may lack the necessary impact resistance or UV stability, which can lead to project failures. It's important to ask questions, test samples, and avoid assumptions. This approach ensures that the selected material aligns with project goals, ultimately enhancing overall quality and satisfaction.

EVA rubber, or ethylene-vinyl acetate, offers unique properties that make it a popular choice for various applications. It stands out due to its flexibility, lightweight nature, and excellent resilience. According to industry reports, EVA rubber can withstand temperatures ranging from -70°F to 150°F. This wide temperature range enhances its versatility in both indoor and outdoor projects.

The material is also known for its strong shock absorption capabilities. This quality is essential in industries like footwear, where cushioning is crucial. Research indicates that EVA rubber can reduce impact forces by up to 40%. This statistic highlights its importance in protective gear and sporting equipment. However, some users note that while EVA is durable, it may not always provide the same lifespan as alternatives like thermoplastic elastomers.

Furthermore, EVA rubber is often praised for its chemical resistance. It can resist various solvents and acids, making it suitable for more demanding environments. Yet, it’s important to remember that not all EVA formulations are created equal. Users should carefully assess their project needs against the material's properties. A misalignment can lead to underwhelming performance or premature wear.

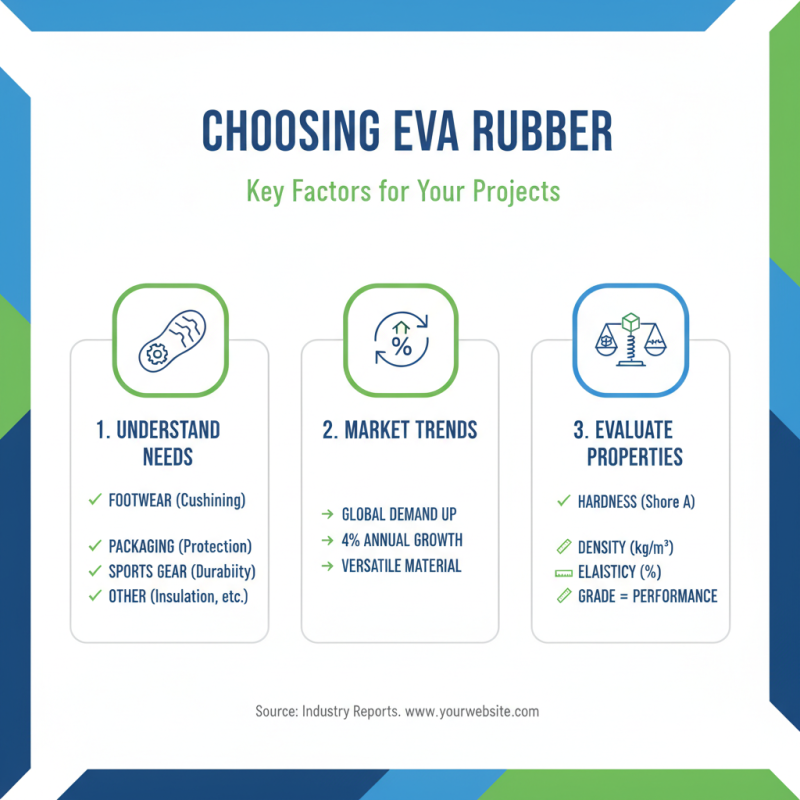

Choosing the right Eva rubber for your projects begins with understanding your specific requirements. Eva rubber is popular in various applications, including footwear, packaging, and sports equipment. According to industry reports, demand for Eva rubber has been growing at a steady rate of 4% annually. Evaluating the hardness, density, and elasticity of Eva rubber is crucial. Different projects may require different grades, which determines performance and durability.

Consider the environment where your product will be used. For instance, if you need rubber for outdoor activities, look for UV-resistant options. Industry experts suggest that around 70% of project failures stem from improper material selection. Another critical factor is the production method. A foam variant may be ideal for cushioning, while a solid grade offers better support.

Additionally, keep in mind the cost-effectiveness of your choice. If the project budget is tight, settling for lower quality might seem tempting. However, this often leads to higher long-term costs due to frequent replacements. Finding the balance between quality and budget is essential. Understanding how these variables play together is vital for a successful outcome.

When choosing the right EVA rubber for your projects, understanding the different types is essential. EVA, or ethylene-vinyl acetate, comes in various formulations, each offering unique properties. Some EVA rubbers are soft and flexible, while others are firmer, providing different levels of support. For footwear, softer EVA is often preferable. It enhances comfort and absorbs shock effectively. However, it may wear faster compared to firmer options.

On the other hand, firm EVA rubber is ideal for construction applications. It resists wear and tear quite effectively. This type can withstand heavier loads and harsh conditions. Yet, it may lack the cushioned feel that consumers expect in everyday items. Choosing the right type often requires testing and reflection. Evaluating your project's specific needs is crucial. Consider both the intended use and the environment the material will face. The best choice might not always be apparent on first glance, leading to potential misjudgments.

| Eva Rubber Type | Density (kg/m³) | Hardness (Shore A) | Elasticity (%) | Temperature Resistance (°C) | Applications |

|---|---|---|---|---|---|

| Standard EVA | 400 - 600 | 45 - 60 | 150 - 300 | -30 to 70 | Footwear, Sports Equipment |

| EVA Foam | 25 - 150 | 30 - 50 | 200 - 400 | -40 to 60 | Padding, Insulation |

| High-Performance EVA | 500 - 800 | 60 - 80 | 100 - 250 | -20 to 90 | Industrial Applications, Medical Devices |

| Colorful EVA | 350 - 550 | 40 - 55 | 120 - 300 | -30 to 70 | Toys, Craft Projects |

| Foamed EVA | 100 - 200 | 20 - 40 | 300 - 500 | -50 to 60 | Soundproofing, Packaging |

When selecting EVA rubber for your projects,

cost and availability play huge roles.

Different suppliers offer various pricing options. Evaluating these can be tricky. Don't just rely on one source.

Compare prices across multiple suppliers to ensure you get a fair deal. Sometimes, lower prices might come with hidden costs,

like shipping fees.

Availability is equally important.

Some types of EVA rubber are more common than others. If a specific formulation is needed, it may not be readily available.

This can lead to delays in your project timeline. Some suppliers might have stock but at a premium price.

You may find it beneficial to reach out to manufacturers directly. This can sometimes uncover options that aren't listed online.

Consider bulk purchasing if you foresee ongoing needs.

While the upfront cost may seem high, it often leads to savings in the long run. Still, ensure you have accurate estimates of your requirements.

Overestimating could lead to excess material, which can be wasted. Reflect on your project needs carefully to avoid unnecessary expenses.

When selecting EVA rubber for your projects, understanding application considerations is key. EVA rubber is versatile and can be used in various fields, including footwear, packaging, and toys. Its properties, like flexibility and durability, can enhance the effectiveness of your projects.

Tips: Consider the specific environment where your project will be used. For outdoor applications, choosing a UV-resistant EVA can make a significant difference. Ensure the thickness is appropriate for stress and wear.

A common oversight is ignoring the temperature range. EVA may become too soft in extreme heat or brittle in cold weather. Assess the conditions before finalizing your choice. If you're uncertain, test small samples first. This step can provide insights into the material's performance.

Additionally, while EVA offers great benefits, it has limitations. Sometimes, the material’s cushioning might not suffice for heavy-duty use. Evaluating the intended end-use is crucial. Balancing your project's needs with EVA's characteristics can lead to better outcomes.