In the world of materials, selecting the right kind of foam can significantly impact the success of any project. Rubber foam, known for its versatility and durability, is a popular choice across various applications including construction, automotive, and consumer products. According to Dr. Emily Johnson, a leading expert in the rubber foam industry, “Choosing the correct type of rubber foam not only enhances the performance of your project but also guarantees long-lasting results.” Her insight underscores the importance of understanding the unique properties and benefits of different rubber foams.

When embarking on a project that requires rubber foam, it is essential to consider factors such as density, tensile strength, and thermal insulation properties. Each of these characteristics plays a crucial role in determining the suitability of rubber foam for your specific needs. Moreover, the right selection can lead to improved efficiency, cost-effectiveness, and sustainability in your final product. In this article, we will explore key tips for choosing the best rubber foam, ensuring that you make an informed decision that aligns with your project's goals.

Rubber foam is a versatile material used in various applications, ranging from industrial to consumer products. There are several types of rubber foam, each tailored for specific uses. For instance, closed-cell rubber foam is commonly employed in thermal insulation and soundproofing due to its excellent barrier properties. This type minimizes air and moisture penetration, making it ideal for HVAC systems and marine applications.

On the other hand, open-cell rubber foam is characterized by its softer texture and higher compressibility, which makes it suitable for cushioning and padding in automotive and furniture applications. It provides better airflow and is often used in mattresses and pillows for added comfort. Understanding the differences between these types of rubber foam can significantly impact the effectiveness and longevity of your project, ensuring you select the right material for your specific needs.

| Type of Rubber Foam | Density (kg/m³) | Typical Applications | Benefits |

|---|---|---|---|

| Open Cell Foam | 25-60 | Sound insulation, cushioning | Lightweight, breathable |

| Closed Cell Foam | 40-150 | Marine applications, thermal insulation | Water-resistant, durable |

| Neoprene Foam | 30-100 | Wetsuits, gaskets | Resistant to oils and chemicals |

| EPDM Foam | 40-100 | Weather stripping, seals | Highly resistant to UV and ozone |

| SBR Foam | 20-80 | Shock absorbers, padding | Cost-effective, versatile |

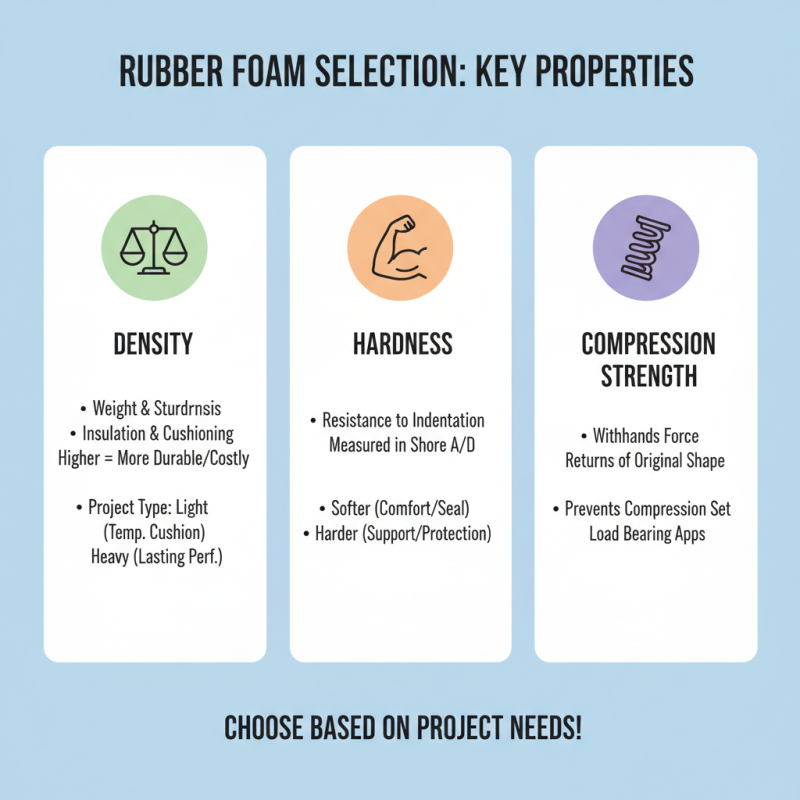

When selecting rubber foam for your project, evaluating physical properties like density, hardness, and compression strength is crucial. Density determines the foam's weight and sturdiness, affecting its insulation and cushioning abilities. Higher density foam typically offers better durability but can be more expensive. Consider the specific requirements of your project; for example, lightweight densities are suitable for applications like temporary cushioning, while heavy-duty projects may demand denser options for lasting performance.

Hardness is another significant factor; it influences both comfort and support. Foam hardness is rated on the Shore scale, which measures how firm the foam feels. A softer foam may be ideal for mattresses or seat cushions, whereas a firmer foam can provide better support in industrial applications.

When assessing compression strength, pay attention to how much weight the foam can withstand before deforming. This property is vital for applications that involve heavy loads or frequent use. Tip: Always request samples to test the foam for your specific use case, as this will help you make a more informed decision based on firsthand experience.

When selecting the best rubber foam for your project, it's crucial to assess its

thermal and acoustic insulation properties. Rubber foam,

particularly when made from expanded Styrene-Butadiene Rubber (SBR), can offer excellent insulation qualities.

Recent studies highlight the innovative use of rubber composites that incorporate leather waste, enhancing their

thermal resistance and sound attenuation. This eco-friendly approach

not only improves the insulation performance but also addresses waste management

by repurposing materials.

Moreover, the thermal insulation benefits of rubber foam are significant for energy efficiency.

It helps maintain indoor temperatures, reducing the reliance on heating and cooling systems, which can lead to lower

energy costs. In addition, its acoustic insulation capabilities help create

quieter living environments, making it suitable for residential areas exposed to traffic noise or other disturbances.

By considering these factors, you can ensure that the rubber foam you choose not only meets your project requirements

but also contributes to sustainability and comfort.

When selecting rubber foam for your project, understanding the cost-benefit aspects is essential to ensure you stay within budget while achieving your desired quality. According to a report by the Global Market Insights Group, the rubber foam market was valued at over $5 billion in 2022 and is projected to grow due to its versatility and efficiency in various applications. This growth indicates that there are many options available, but it also calls for a careful assessment of how to balance cost against performance.

Investing in high-quality rubber foam may seem expensive upfront, but the long-term benefits can outweigh the initial costs. Research from the American Institute of Chemical Engineers suggests that using superior materials can lead to a decrease in maintenance expenses by 20-30% over the lifespan of the product. Moreover, durable rubber foam exhibits better insulation properties, potentially reducing energy costs in applications like HVAC systems by 15-25%. By weighing these factors and considering the overall lifecycle costs, you can make a more informed decision that aligns with both your budget and project needs.

This chart illustrates the cost and durability of different types of rubber foam. As the density increases, the cost also rises while durability improves significantly, providing valuable insights for budgeting and project planning.

When selecting rubber foam materials for your project, sustainability should be a primary consideration. The rubber industry has made significant strides toward eco-friendly practices, enabling consumers to make more informed choices. According to a report by the Global Industry Analysts, the demand for sustainable rubber foams is projected to grow by 6.5% annually, driven by increasing environmental awareness and stricter regulations on waste and emissions. Choosing naturale or recycled rubber foams not only reduces the carbon footprint but also supports a circular economy, where materials are reused and recycled, minimizing landfill waste.

Tips for selecting sustainable rubber foam include evaluating the source of the material. Opt for manufacturers who use eco-friendly extraction processes and prioritize recycling initiatives. Additionally, consider the certifications of the rubber foam products; those with certifications like Global Organic Latex Standard (GOLS) or OEKO-TEX can assure consumers of their sustainability credentials. Another important tip is to assess the longevity and durability of the foam, as high-quality materials can reduce the need for replacements, further contributing to environmental sustainability.

By making thoughtful choices in rubber foam selection, you can ensure that your project aligns with sustainable practices while still meeting performance requirements. The increased focus on eco-friendly materials not only benefits the environment but also enhances brand image and consumer trust in an increasingly eco-conscious marketplace.