When it comes to protecting your products during shipping and storage, choosing the right Eva Foam Packaging solutions is essential. Eva foam, known for its lightweight yet durable properties, offers excellent cushioning and can be customized to fit various shapes and sizes. However, with a multitude of options available, navigating through these choices can be daunting. In this blog, we will explore seven essential tips to help you make an informed decision. From understanding the specific needs of your products to considering factors such as cost, thickness, and environmental impact, our guide will ensure you select the perfect Eva Foam Packaging that not only safeguards your items but also enhances your brand’s reputation. Join us as we dive into the best practices for choosing Eva foam that meets your unique packaging requirements.

When selecting EVA foam packaging solutions, several key factors must be considered to ensure optimal performance and protection for your products. The type of EVA foam is crucial; standard EVA films are commonly used for general packaging needs, while anti-PID EVA films specifically cater to solar panel encapsulation applications, offering enhanced durability against environmental factors. Understanding the specific requirements of your product will help you choose the right type of foam to maximize protection and longevity.

Another significant aspect to consider is the production method. EVA foam can be produced through extrusion or casting processes, each offering distinct benefits depending on the intended application. Extrusion generally provides a uniform thickness and is ideal for mass production, while casting allows for greater flexibility in thickness and custom shapes. Evaluating these production methods in relation to your packaging needs can lead to more efficient and effective solutions, ultimately enhancing your product's market competitiveness.

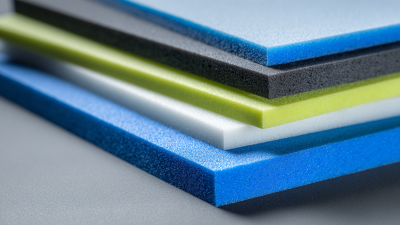

When selecting Eva foam for packaging, understanding the different types available is crucial to meeting your specific needs. Eva foam comes in various densities and formulations, each suitable for different applications. For instance, Cross-linked Eva foam offers enhanced durability and resistance to moisture, making it an ideal choice for products that require extra protection against environmental factors. On the other hand, non-cross-linked Eva foam is softer and more flexible, which can be advantageous for items that need to be snugly wrapped without risking damage.

Another key consideration is the thickness and color of the Eva foam. Thicker foam provides better shock absorption, which is essential for fragile items, while a variety of colors can help with branding and aesthetic appeal. Additionally, one can find foam with special properties, such as UV resistance or anti-static features, which are important for packaging electronics or outdoor products. By thoroughly understanding the types of Eva foam available and considering these factors, you can make an informed decision that will enhance your packaging efficiency and product protection.

| Tip Number | Tip Description | Type of EVA Foam | Recommended Use |

|---|---|---|---|

| 1 | Understand the density of EVA foam for durability. | High Density EVA | Heavy equipment packaging |

| 2 | Consider the thickness based on the product dimensions. | Medium Density EVA | Fragile items like electronics |

| 3 | Evaluate the foam's shock absorption properties. | Low Density EVA | Sensitive instruments |

| 4 | Ensure the EVA foam is chemically resistant if needed. | Chemical-Resistant EVA | Chemical storage |

| 5 | Check for UV stability if exposed to sunlight. | UV-Resistant EVA | Outdoor applications |

| 6 | Select a color that suits branding and visibility. | Colored EVA | Promotional products |

| 7 | Test for temperature resistance if applicable. | Heat-Resistant EVA | Electronics in high heat areas |

When evaluating the durability and protection level of EVA foam options for packaging, it's essential to consider the specific application and the materials being protected. Research indicates that EVA foam exhibits excellent shock absorption capabilities, with a reported compression set of less than 5% after extensive testing, making it an ideal choice for protecting fragile items during transportation. This durability ensures that products like electronics or delicate components remain safe even under harsh conditions.

Furthermore, the protection level offered by EVA foam can significantly reduce the risks associated with impact damage. Industry studies show that materials with a density of 25-30 kg/m³ provide optimal cushioning without adding excessive weight, which is crucial for cost-effective shipping solutions. The ability of EVA foam to maintain its integrity over time while providing consistent protection makes it a preferred choice among manufacturers looking to enhance product safety and minimize return rates due to damage. By selecting the right EVA foam packaging solutions, businesses can effectively safeguard their inventory and improve overall customer satisfaction.

When sourcing EVA foam packaging solutions, cost-effectiveness is a primary concern for many businesses. One crucial strategy is to evaluate multiple suppliers to find the best combination of price and quality. It's important to consider not just the initial cost but also the long-term value of the foam. High-quality EVA foam may come with a higher upfront cost, but its durability and protection can save money in potential damage claims and replacements.

Another effective method is to consider bulk purchasing options. Many suppliers offer significant discounts for larger orders, which can substantially reduce costs per unit. Additionally, assessing the specific needs of your products can help you avoid overspending on unnecessary features. Tailoring the foam thickness and density to match your product requirements can lead to more efficient packaging solutions, minimizing waste and driving down expenses while ensuring optimal protection during transit.

When selecting EVA foam packaging solutions, sustainability should be a key consideration. The environmental impact of materials can significantly influence not only brand perception but also compliance with regulations and consumer demand. Opting for EVA foam that is recyclable and made from sustainable processes helps reduce the overall carbon footprint. Look for suppliers that provide transparency regarding their manufacturing practices, ensuring that eco-friendly materials are prioritized.

Incorporating tips for a sustainable choice, start by evaluating the lifecycle of the EVA foam you intend to use. Consider how the material will be disposed of after its initial purpose. Additionally, seek out EVA foam options that are non-toxic and free from harmful chemicals, which not only benefits the environment but also promotes safety for end-users. It's also beneficial to explore manufacturers that focus on reducing waste in their production processes, leading to more efficient and sustainable outcomes.

As you delve into your options, keep in mind that investing in high-quality, sustainable EVA foam packaging is not just a trend but a vital step towards corporate responsibility. Making informed choices today can contribute significantly to a greener future while also enhancing your product's appeal in an increasingly eco-conscious market.