In the realm of crafting and design, the versatility and practicality of the Black Eva Sheet have captured the attention of professionals and enthusiasts alike. As John Carter, a renowned expert in materials used for creative projects, aptly states, "The Black Eva Sheet is not just about aesthetics; it's about finding the perfect balance between form and function." This insight underscores the significance of understanding how to leverage this material effectively to enhance the outcome of various projects.

The Black Eva Sheet is celebrated for its lightweight, durable, and malleable qualities, making it an ideal choice for everything from prototyping to intricate designs. Whether you are creating custom decorations, educational tools, or intricate models, employing the right techniques can make a significant difference. This article aims to guide you through ten essential tips for utilizing Black Eva Sheet in your projects, empowering you to maximize its potential while achieving professional results. By following these strategies, you will not only elevate the quality of your work but also transform your creative process into an exhilarating experience.

Black Eve sheets, commonly made from ethylene-vinyl acetate (EVA), are prized in various industries for their versatility and unique properties. Known for their excellent flexibility and durability, EVA sheets can withstand varying temperatures and resist UV rays, making them ideal for both indoor and outdoor applications. According to a report by Grand View Research, the global EVA market size is expected to reach USD 8.76 billion by 2025, highlighting the growing demand for materials like black EVA across sectors such as automotive, packaging, and consumer goods.

One of the noteworthy properties of black EVA sheets is their sound absorption capabilities, which can be crucial in applications ranging from soundproofing to cushioning in sporting equipment. A study from the Journal of Acoustical Society of America indicated that materials with sound-dampening characteristics can reduce noise transmission by up to 30%, making black EVA a choice material for those seeking to enhance acoustic performance in their projects. Additionally, the lightweight nature of EVA sheets contributes to lower transportation costs and easier handling, further amplifying their appeal within the construction and design industries.

When selecting the appropriate thickness of black EVA sheets for your projects, it’s vital to consider the specific requirements of your application. According to industry reports from materials research organizations, EVA sheets come in various thicknesses ranging typically from 1mm to 25mm. Thicker sheets offer enhanced durability and are ideal for structural applications, while thinner sheets can provide flexibility and ease of manipulation for intricate designs.

Tip 1: For applications involving heavy load-bearing, such as sports flooring or outdoor equipment, opting for a thickness of 10mm or more is advisable. This ensures that the material can withstand pressure and impact without compromising performance.

Tip 2: Conversely, if your project requires detailed cuts and designs, thinner sheets, around 2-3mm, allow for easier handling. A recent industry analysis highlighted that many manufacturers have shifted to using EVA sheets of about 3mm thickness for prototype developments due to their balance of rigidity and pliability.

Pay attention to the specific environmental conditions your project may face. Research indicates that thicker sheets offer better resistance to UV radiation and moisture, making them suitable for outdoor applications. In contrast, for indoor projects, lighter sheets may suffice, allowing for more intricate designs while saving costs and reducing material weight.

When working with black Eva sheet, precise cutting techniques are essential to ensure clean edges and accurate shapes for your projects. One effective method is to use a sharp craft knife or a rotary cutter. Always start with a straight edge or a ruler to guide your cuts, preventing any unwanted slips that could compromise the quality of your work. Additionally, consider using a cutting mat underneath the sheet to protect your surfaces and preserve the sharpness of your blades.

Another tip for achieving neat cuts is to score the material before making deeper cuts. By lightly running the knife along the desired cutting line, you create a groove that guides your tool for a cleaner finish. This technique is especially useful for intricate designs or when working with thicker sheets. Moreover, practicing on scrap pieces can help you gain confidence in your cutting technique before moving on to the actual project.

For those looking to enhance their cutting accuracy further, using a grid ruler can help maintain straight lines. Align the grid with your cutting line, and you'll have a visual reference that makes it easier to follow through. Combine this with consistent pressure during the cutting process to avoid tearing the Eva sheet, ensuring that each piece fits perfectly into your project components.

When working with black EVA sheet, selecting the right adhesive is crucial for achieving a strong and durable bond. There are various adhesive options available, each with its own set of properties that make it suitable for different applications. For instance, water-based adhesives are popular for their ease of use and quick drying times. They offer a decent level of bonding strength and are ideal for projects that require a more flexible finish. These adhesives also tend to be less toxic and are easier to clean up, making them suitable for home or craft projects.

On the other hand, contact adhesives can provide a stronger, more permanent bond. They are particularly useful for heavy-duty applications where a robust hold is necessary. When using contact adhesive, it's important to apply it to both surfaces and allow it to become tacky before joining them together, ensuring a solid bond. For high-temperature environments or outdoor projects, consider using specialty adhesives that are formulated to withstand varying conditions, ensuring that your EVA sheets remain securely attached regardless of the setting. Always consult the adhesive's specifications to match it with your project requirements for optimal results.

| Tip Number | Tip Description | Adhesive Options | Bonding Strength |

|---|---|---|---|

| 1 | Clean the surface of the EVA sheet before applying adhesive. | Contact Adhesive | High |

| 2 | Use a roller or brush for even adhesive application. | Spray Adhesive | Medium |

| 3 | Allow adequate curing time for the adhesive. | Hot Glue | High |

| 4 | Test the adhesive on a small area first. | EVA Glue | Medium |

| 5 | Ensure proper temperature conditions for bonding. | Instant Adhesive | Low |

| 6 | Clamp or hold materials together after applying adhesive. | Silicone Adhesive | Medium |

| 7 | Avoid excessive pressure during bonding. | Fabric Glue | Low |

| 8 | Store EVA sheets and adhesives properly to extend their lifespan. | Any All-Purpose Adhesive | Variable |

| 9 | Use protective gear when working with adhesives. | Contact Cement | High |

| 10 | Consult manufacturer guidelines for best results. | Recommended Adhesive | High |

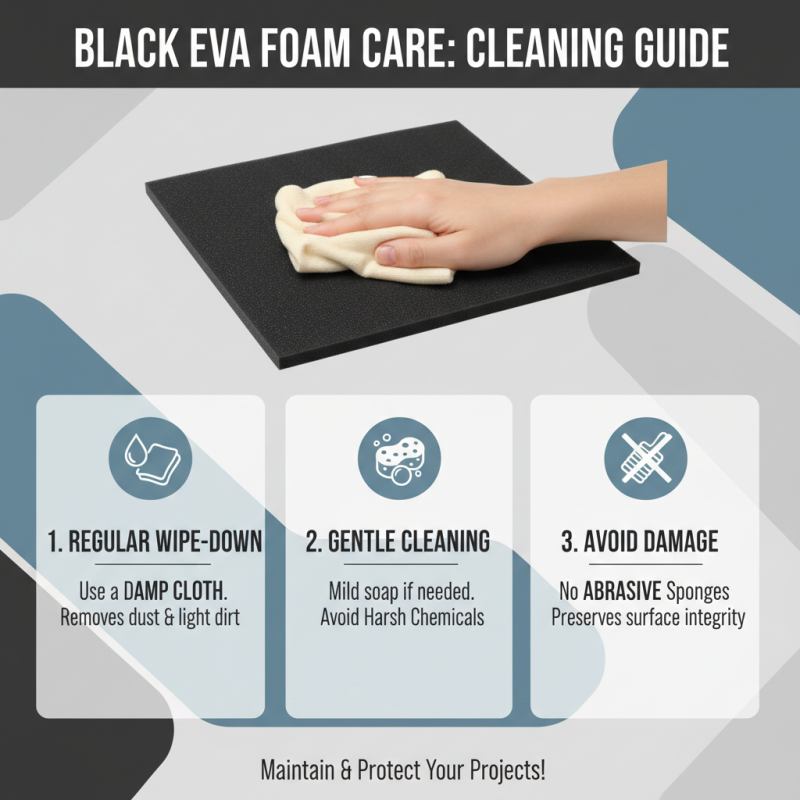

When working with black EVA sheets, maintaining and caring for your projects is essential to ensure longevity and effectiveness. One crucial aspect of proper maintenance involves regular cleaning. EVA is resistant to moisture and dirt, but over time, dust and debris can accumulate. A gentle wipe with a damp cloth is typically sufficient to keep your sheets looking clean and fresh. Avoid using harsh chemicals or abrasive sponges, as these can damage the surface and affect the material's integrity.

Another important consideration is storage. When not in use, keeping your EVA sheets stored in a cool, dry place can significantly prolong their life. Exposure to direct sunlight can lead to fading and degradation of the material, so it's advisable to store them away from UV light sources. Additionally, stacking or placing heavy objects on top of your EVA projects may cause warping or deformation. Using proper storage solutions, such as flat bins or specialized cases, helps maintain their shape and prevents damage over time. By implementing these care techniques, your black EVA sheets will continue to be a reliable choice for various creative endeavors.