The versatility and practicality of PE EVA Foam Sheets have made them a staple in various industries, including construction, automotive, and consumer goods. According to a report by MarketsandMarkets, the global foam market is projected to reach over USD 143 billion by 2026, with an increasing demand for lightweight materials that offer superior cushioning and insulation properties. This growth underscores the importance of understanding how to effectively use PE EVA Foam Sheets in a wide range of projects.

In the realm of DIY crafts, prototyping, and product packaging, the unique characteristics of PE EVA Foam Sheets, such as their water resistance and ease of manipulation, open up a world of possibilities. A study by Grand View Research highlights that the crafting and hobby market is expected to grow significantly, suggesting an elevated interest in materials like PE EVA Foam Sheets among both amateur and professional makers. By employing strategic techniques and understanding the material's best practices, users can enhance both the functionality and aesthetics of their projects.

This article aims to provide ten essential tips for effectively utilizing PE EVA Foam Sheets, ensuring that both novice and experienced creators can maximize their potential in innovative ways. Whether it's for artistic endeavors or practical applications, these insights will empower you to integrate this remarkable material into your work seamlessly.

PE EVA foam sheets are versatile materials known for their lightweight and flexible properties, making them suitable for a variety of applications. Composed primarily of polyethylene (PE) and ethylene-vinyl acetate (EVA), these foam sheets exhibit excellent shock absorption and insulation capabilities. This makes them ideal for use in sports equipment, protective gear, and children's play areas. Additionally, their water-resistant nature enables them to perform well in outdoor environments, further expanding their usability.

One of the key attributes of PE EVA foam sheets is their ease of fabrication. They can be easily cut, shaped, and adhered to other materials, allowing for creative projects ranging from crafting to industrial applications. The foam sheets also come in various thicknesses and densities, catering to specific requirements in different projects. Furthermore, their vibrant colors and smooth surface finish make them an appealing choice for decorative elements in interior design and event décor.

Understanding these properties can significantly enhance your ability to utilize PE EVA foam sheets effectively in your projects.

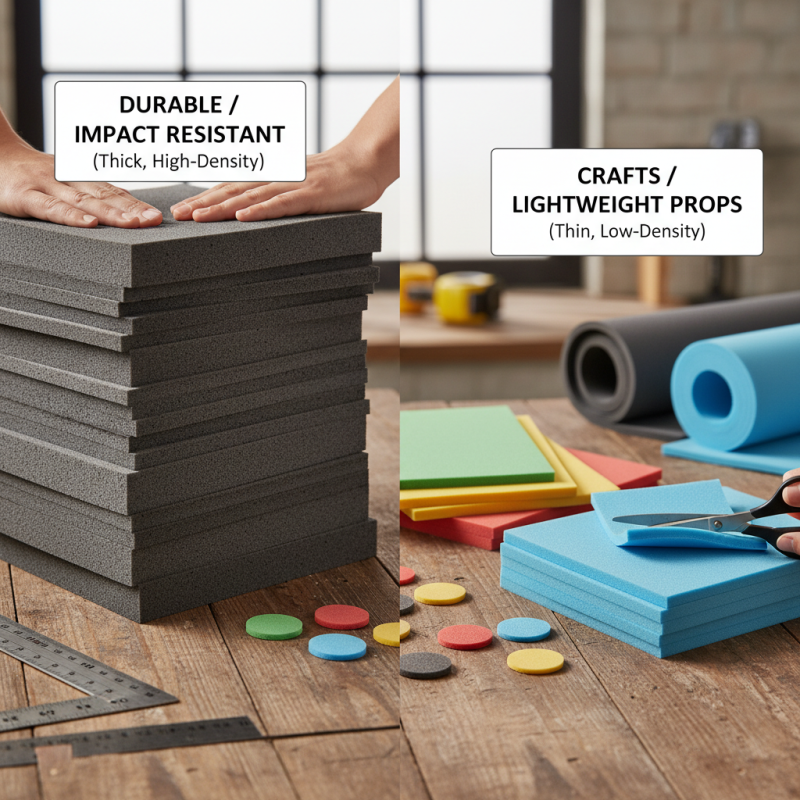

When working with PE EVA foam sheets, one of the most critical factors to consider is the thickness and density of the material. The right thickness ensures that the foam can support the intended application, whether it's padding, insulation, or structural support. For instance, thicker sheets are often preferred for projects that require durability and impact resistance, such as flooring or protective gear. Conversely, lighter applications, like craft projects or lightweight props, may benefit from thinner sheets that are easier to cut and manipulate.

Density also plays a significant role in the performance of the foam sheets. Higher density foam tends to offer better support and resilience, making it ideal for use in products that endure frequent use or stress. On the other hand, lower density foam is often softer and more pliable, suitable for projects requiring flexibility and comfort, like cushioning for costumes or soft toys. When selecting foam sheets for your project, it is essential to balance these factors to achieve the desired outcome effectively, ensuring that the foam not only meets functional needs but also enhances the overall quality of the finished product.

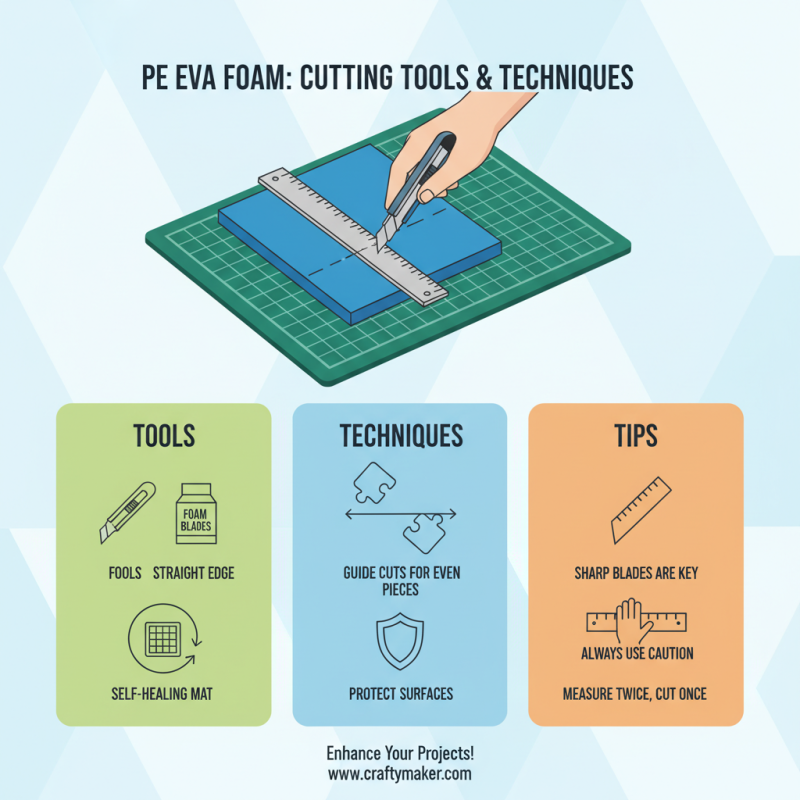

When it comes to working with PE EVA foam sheets, having the right tools and techniques can greatly enhance the efficiency and quality of your projects. One of the most important aspects is selecting the proper cutting tool. For clean and precise cuts, consider using a sharp utility knife or a foam-specific blade. A straight edge or ruler can help guide your cuts and ensure evenly sized pieces. Remember to always cut on a self-healing mat to protect your surfaces and prolong the life of your blades.

In addition to cutting, shaping PE EVA foam can add unique elements to your designs. Heat can be your best friend when bending or molding foam sheets. A heat gun allows you to soften the material, making it easier to manipulate into the desired shape. As you shape the foam, keep the heat source at a safe distance to avoid scorching the material. Once shaped, the foam can retain its form; however, give it time to cool completely before handling to ensure it sets correctly.

Another valuable tip is to use adhesives designed for foam when assembling your pieces. Foam-compatible adhesives will not only provide strong bonds but also maintain the flexibility of the sheets. For a smooth finish, sand the edges lightly after cutting, ensuring that any contact points are clean for better adhesion. With these techniques and tips in mind, you can achieve professional-level results in your foam projects while working efficiently and effectively.

When working with PE EVA foam sheets in your projects, selecting the right adhesives and fastening techniques is crucial to ensure durability and a clean finish. A strong adhesive suitable for foam, such as contact cement or hot glue, can create a reliable bond, while avoiding products that may dissolve the foam is essential. Consider testing your adhesive on a small piece of foam first to ensure compatibility and to achieve the best results.

Tip 1: Always apply the adhesive evenly across the surface to avoid lumps, which can lead to uneven bonding. Using a brush or a roller can help achieve a smooth layer. Additionally, allow the adhesive to slightly cure before bringing the pieces together, as this promotes a stronger bond.

Tip 2: In some projects, mechanical fastening methods, such as staples or screws, can provide additional reinforcement, especially in areas experiencing movement or stress. When using screws, pre-drilling holes can prevent the foam from tearing. Soft washers can be employed to distribute the pressure and avoid damaging the foam surface.

By combining the right adhesives with effective fastening techniques, you can enhance the longevity and stability of your PE EVA foam creations.

When it comes to enhancing the aesthetic appeal of your PE EVA foam projects, proper painting and sealing techniques can make all the difference. Selecting the right type of paint is essential; acrylic paint is often favored for its adherence and vibrant finish. It allows the foam to maintain its flexibility while offering a variety of colors to bring your designs to life. Before applying the paint, it's recommended to clean the foam surface and, if necessary, use a primer specifically designed for foam materials. This step ensures that the paint adheres well and provides even coverage.

Once you have achieved the desired color through painting, sealing the surface is the next crucial aspect. A sealant, such as a clear acrylic spray or liquid sealant designed for use on foam, can protect your painted surface from scratches, moisture, and UV damage. It's best to apply several thin coats rather than a single thick layer to avoid dripping and ensure an even finish. Allow each coat to dry thoroughly before applying the next one. This protective layer not only enhances the longevity of your artwork but also gives it a polished, professional look, making your PE EVA foam projects stand out even more.