In the ever-evolving landscape of manufacturing, selecting the right materials is crucial to achieving efficiency and quality. Among the myriad options available, Eva Sheet Roll has emerged as a top choice for many industry leaders. According to a report by Smithers Pira, the global demand for ethylene-vinyl acetate (EVA) is projected to reach over 3 million tons by 2026, driven by its applications across various sectors, from packaging to automotive and footwear. This rise can be attributed to the material's remarkable properties, including durability, flexibility, and resistance to UV light and chemicals. The versatility of Eva Sheet Roll not only enhances production processes but also improves the sustainability profiles of manufactured products, aligning with the increasing push for eco-friendly solutions in the industry. As manufacturers seek to optimize their operations, understanding why Eva Sheet Roll stands out as the best choice is essential for maintaining competitive advantage and meeting consumer demands.

When it comes to optimizing production efficiency in manufacturing, EVA (Ethylene Vinyl Acetate) sheet rolls stand out as an exceptional choice. One of the primary advantages of using EVA sheet rolls is their lightweight yet durable nature. This quality ensures that manufacturers can handle and transport materials with ease, reducing downtime and improving workflow on the factory floor. The flexibility of EVA allows for easy integration into various processes, enabling manufacturers to adapt to changing production demands without sacrificing quality.

Another significant benefit of EVA sheet rolls is their excellent cushioning properties. This ensures that products are protected during processing and transportation, minimizing damage and waste. The shock-absorbing characteristics of EVA not only enhance the safety of the goods but also contribute to substantial cost savings over time. Additionally, the versatility of EVA in terms of customization allows manufacturers to tailor the thickness and softness of the sheets to meet specific production requirements, further streamlining operations. By implementing EVA sheet rolls, manufacturers can boost their overall productivity and maintain a competitive edge in a fast-paced industry.

When it comes to choosing materials for manufacturing, cost-effectiveness is a crucial factor. EVA sheet rolls stand out in this regard, offering competitive pricing that makes them an attractive option for various applications. Unlike other materials that can dramatically hike in price due to growing demand or limited supply, EVA sheet rolls have established themselves as a stable and affordable choice. With their excellent properties—durability, flexibility, and resistance to environmental factors—EVA sheets provide significant value without compromising quality.

Moreover, manufacturers can benefit from the versatility of EVA sheet rolls across different sectors, including packaging, automotive, and construction. This adaptability ensures that businesses can maximize their investment, reducing the need to source multiple materials for different applications. By choosing EVA sheet rolls, companies not only save on material costs but also streamline their procurement processes, enhancing overall efficiency and productivity. In a competitive market, these advantages can give manufacturers a significant edge by optimizing both budget and operational management.

When evaluating materials for manufacturing, durability is a critical factor that cannot be overlooked.

EVA (Ethylene Vinyl Acetate) sheet rolls are well-regarded for their impressive resilience, frequently exceeding industry standards and performing excellently under stress tests.

Their ability to withstand harsh conditions makes EVA sheet rolls suitable for a variety of applications, from automotive components to industrial packaging.

In rigorous testing scenarios, these sheets demonstrate remarkable

impact resistance,

tensile strength, and reduced wear over time, establishing them as a reliable choice for manufacturers seeking durability.

When evaluating materials for manufacturing, durability is a critical factor that cannot be overlooked.

EVA (Ethylene Vinyl Acetate) sheet rolls are well-regarded for their impressive resilience, frequently exceeding industry standards and performing excellently under stress tests.

Their ability to withstand harsh conditions makes EVA sheet rolls suitable for a variety of applications, from automotive components to industrial packaging.

In rigorous testing scenarios, these sheets demonstrate remarkable

impact resistance,

tensile strength, and reduced wear over time, establishing them as a reliable choice for manufacturers seeking durability.

Moreover, the versatility of EVA sheet rolls enhances their appeal in manufacturing. They maintain flexibility while exhibiting substantial resistance to cracking,

UV rays, and moisture, which is essential in environments where exposure to various elements is common.

By choosing EVA, manufacturers can ensure that their products not only meet but surpass durability expectations, thereby reducing the likelihood of product failure and ensuring long-term performance.

This combination of strength and adaptability makes EVA sheet rolls a wise investment for any manufacturing operation focused on

quality and longevity.

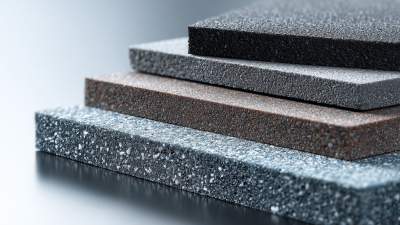

EVA sheet rolls have become a staple in various manufacturing sectors due to their remarkable versatility. The lightweight, elastic nature of EVA (ethylene-vinyl acetate) makes it an ideal material for applications ranging from packaging and automotive to healthcare and sports. Its ability to absorb shock and provide cushioning is particularly beneficial in manufacturing processes that require protective packaging and safety equipment. This adaptability not only helps in meeting industry-specific demands but also enhances overall product quality.

EVA sheet rolls have become a staple in various manufacturing sectors due to their remarkable versatility. The lightweight, elastic nature of EVA (ethylene-vinyl acetate) makes it an ideal material for applications ranging from packaging and automotive to healthcare and sports. Its ability to absorb shock and provide cushioning is particularly beneficial in manufacturing processes that require protective packaging and safety equipment. This adaptability not only helps in meeting industry-specific demands but also enhances overall product quality.

Moreover, EVA sheet rolls offer excellent resistance to UV rays, moisture, and chemicals, making them suitable for outdoor applications and harsh environments. Their ease of processing allows manufacturers to customize sheets for specific needs, whether it involves die-cutting, laminating, or welding. As industries continue to evolve, the demand for materials like EVA that can meet diverse and challenging requirements is on the rise. This trend positions EVA sheet rolls as a leading choice in modern manufacturing, bridging the gap between functionality and performance.

When considering materials for modern manufacturing, the environmental impact is a crucial factor that cannot be overlooked.

EVA sheet roll stands out not only for its versatility but also for its impressive sustainability credentials. Made from ethylene-vinyl acetate, EVA is a non-toxic thermoplastic that can be easily recycled, reducing waste and promoting a circular economy.

Manufacturers are increasingly prioritizing eco-friendly materials, and EVA sheet rolls align perfectly with such initiatives, offering a responsible choice without compromising on performance.

Furthermore, the production process of EVA sheet rolls tends to emit fewer harmful pollutants compared to traditional materials. This contributes to a lower carbon footprint and a healthier environment for both workers and the community.

By choosing EVA sheet rolls, manufacturers can embrace sustainable practices that resonate with consumers' growing demand for environmentally responsible products. With innovations in recycling and processing, EVA technology continues to evolve, solidifying its role as a key player in sustainable manufacturing solutions.