In an era where sustainability is at the forefront of innovation, the search for alternatives to traditional materials is more crucial than ever. Rubber foam, widely used in various applications for its cushioning and insulating properties, presents challenges in terms of environmental impact and resource consumption. As we explore innovative alternatives to rubber foam, we unlock the potential for more sustainable solutions that not only meet consumer needs but also contribute to a healthier planet.

This blog delves into the top strategies for identifying and implementing these alternatives, highlighting cutting-edge materials and approaches that can effectively replace rubber foam while enhancing performance and reducing ecological footprints.

Join us on this journey of discovery as we unveil the future of sustainable materials and their role in transforming industries.

In an era where sustainability is at the forefront of innovation, the search for alternatives to traditional materials is more crucial than ever. Rubber foam, widely used in various applications for its cushioning and insulating properties, presents challenges in terms of environmental impact and resource consumption. As we explore innovative alternatives to rubber foam, we unlock the potential for more sustainable solutions that not only meet consumer needs but also contribute to a healthier planet.

This blog delves into the top strategies for identifying and implementing these alternatives, highlighting cutting-edge materials and approaches that can effectively replace rubber foam while enhancing performance and reducing ecological footprints.

Join us on this journey of discovery as we unveil the future of sustainable materials and their role in transforming industries.

As the demand for sustainable materials continues to rise, innovative bio-based foam alternatives are emerging as viable replacements for traditional rubber foam. Recent advancements have led to the development of eco-friendly bio-based foams derived from agricultural byproducts, such as sugarcane bagasse, combined with sodium alginate. These materials not only exhibit enhanced properties but also support scalable production methods, paving the way for broader applications in reducing plastic usage.

Another exciting avenue in this field is the exploration of fungal mycelium-bound bio-foams, which utilize waste biomass as a substrate. This innovative approach not only highlights the potential of agricultural waste in creating sustainable packaging solutions, but also aligns with eco-conscious principles by promoting circular economies. As these bio-foams gain traction in various markets, they offer promising alternatives that address environmental concerns while meeting consumer needs for responsible products.

| Material Type | Source | Biodegradability | Applications | Thermal Insulation (R-value) | Market Availability |

|---|---|---|---|---|---|

| Coconut Foam | Coconut husks | Yes | Mattresses, Cushions | 3.0 | Commercially available |

| Mycelium Foam | Mushroom mycelium | Yes | Packaging, Insulation | 4.0 | Prototype stage |

| Hemp Foam | Hemp fibers | Yes | Automotive, Building | 3.5 | Limited availability |

| Soy-Based Foam | Soybean oil | Yes | Furniture, Insulation | 5.0 | Commercially available |

As the demand for sustainable materials grows, technology plays a crucial role in transforming foam production processes. Traditional rubber foam has significant environmental impacts, from resource depletion to waste generation. However, innovative technologies are paving the way for the adoption of alternative materials that are both eco-friendly and effective in performance. For instance, advancements in biopolymer production enable the creation of foams derived from renewable sources, reducing dependency on petroleum-based products.

Tips: When considering alternatives, it's essential to research the lifecycle of materials. Look for options that not only offer excellent performance but also minimize environmental footprints throughout their use. Companies exploring these alternatives should prioritize partnerships with tech innovators to stay ahead in the market.

Furthermore, cutting-edge manufacturing techniques like 3D printing and additive manufacturing can significantly reduce waste and allow for more precise design capabilities. Such methods enable the production of complex foam structures that meet specific performance requirements while optimizing material use.

Tips: Implementing smart production technologies can lead to enhanced resource efficiency. Businesses should explore integrating artificial intelligence in their processes to forecast material needs and optimize production schedules, ultimately leading to sustainability and cost-effectiveness.

The environmental impact of traditional rubber foam production is becoming increasingly concerning, leading many industries to seek sustainable alternatives. According to a report by the Ellen MacArthur Foundation, the global demand for sustainable materials is projected to reach $400 billion by 2030, highlighting a significant shift towards eco-friendly solutions. Sustainable foam alternatives, such as those derived from plant-based sources or recycled materials, not only help reduce carbon emissions but also minimize landfill waste.

For instance, bio-based foams made from materials like soy or algae have shown to reduce greenhouse gas emissions by up to 30% compared to conventional rubber foams, as documented by the Bioplastic Feedstock Alliance. Furthermore, these alternatives typically require less energy in their production processes, as they can be sourced from renewable resources. With the foam market expected to grow by 4.6% annually, companies embracing sustainable options not only contribute positively to the environment but also position themselves as leaders in an evolving marketplace focused on sustainability.

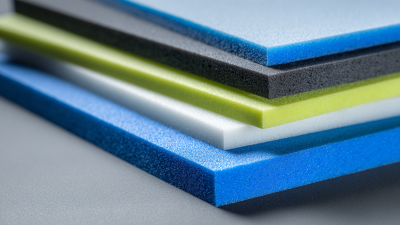

In the quest for sustainable materials, rubber foam has long been a popular choice for various applications, from cushioning in furniture to insulation in construction. However, as environmental concerns rise, the need to explore alternatives that minimize ecological impact has become paramount. A comparative analysis between rubber foam and eco-friendly options reveals the strengths and weaknesses of both materials, shedding light on viable replacements that align with sustainability goals.

Eco-friendly alternatives such as plant-based foams, recycled materials, and mushroom mycelium are gaining traction for their lower carbon footprints and biodegradable properties. Plant-based foams, for instance, leverage natural oils and fibers, offering similar cushioning and insulation performance as rubber foam while being more environmentally friendly. Conversely, while rubber foam is durable and offers excellent resilience, its reliance on non-renewable resources and challenges in disposal raise significant concerns. By evaluating the performance, lifecycle, and ecological footprint of these alternatives against traditional rubber foam, consumers and manufacturers can make informed decisions that prioritize environmental sustainability without sacrificing quality or functionality.

As industries seek sustainable alternatives to traditional rubber foam, several innovative solutions are emerging. For instance, recent research by the Global Environmental Change Journal highlights that bio-based foams made from materials such as corn starch and mushroom mycelium can reduce carbon footprints by up to 30%. These alternatives not only offer environmental benefits but also meet the growing consumer demand for eco-friendly products.

Implementing sustainable foam solutions is more than just a trend—it's becoming a necessity. According to a report by the International Journal of Life Cycle Assessment, transitioning from conventional foams to biodegradable options can cut down waste by approximately 40% in the manufacturing sector. Companies should consider adopting practices such as utilizing local sourcing for raw materials, which reduces transportation emissions, and integrating circular economy principles that promote reusability and recyclability of foam materials. By doing so, businesses can not only improve their sustainability metrics but also strengthen their market position in an increasingly eco-conscious landscape.