As the manufacturing landscape continues to evolve, the demand for sustainable materials has never been more critical. Eva Rubber, known for its lightweight and durable properties, is at the forefront of this transformation. According to a recent report by ResearchAndMarkets, the global EVA (Ethylene-Vinyl Acetate) market is expected to reach USD 10 billion by 2024, growing at a CAGR of over 6% from 2020 to 2024. This surge is driven by its applications in various sectors, including footwear, automotive, and packaging, where eco-friendly solutions are becoming increasingly necessary. Moreover, the shift towards sustainable manufacturing practices is prompting industries to adopt innovations in Eva Rubber production that minimize waste and energy consumption. In this blog, we will explore how advancements in Eva Rubber technologies are set to revolutionize sustainable manufacturing processes, paving the way for a greener future.

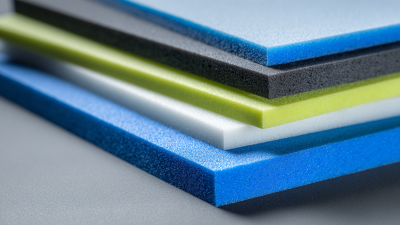

Eva rubber innovations are playing a pivotal role in transforming manufacturing processes, particularly in reducing waste and promoting sustainability. This versatile material, known for its lightweight and durable properties, is increasingly being utilized in industries ranging from footwear to automotive components. By adopting Eva rubber, manufacturers can minimize the environmental impact associated with traditional materials, as Eva can often be recycled or repurposed, leading to less landfill waste.

Moreover, the production methods surrounding Eva rubber are evolving, with advancements focusing on energy efficiency and resource conservation. Techniques such as digital manufacturing and the use of eco-friendly solvents not only enhance the quality of the final products but also significantly decrease the volume of hazardous waste generated. As businesses commit to more sustainable practices, the integration of Eva rubber into their supply chains is becoming a strategic choice, ultimately driving the industry toward a greener future while meeting consumer demands for eco-conscious products.

| Dimension | Impact | Benefits | Current Trends |

|---|---|---|---|

| Material Efficiency | Reduced raw material usage | Cost savings, Lower environmental footprint | Adoption of bio-based EVA |

| Waste Reduction | Minimized production waste | Enhanced sustainability, Improved brand image | Recycling initiatives |

| Energy Consumption | Lower energy usage during production | Decreased operating costs, Lower emissions | Energy-efficient machinery |

| Lifecycle Analysis | Understanding environmental impact | Informed decision-making for sustainability | Increased transparency in supply chains |

| Product Innovation | Development of sustainable products | Market competitiveness, Consumer preference | Smart materials, Customizable solutions |

The production of ethylene-vinyl acetate (EVA) is experiencing a significant transformation as sustainability becomes a top priority in manufacturing processes. However, sourcing sustainable raw materials for EVA production presents various challenges. One major hurdle is the limited availability of bio-based alternatives that can meet the performance standards required by the industry. While many manufacturers are eager to transition to greener options, the supply chain for sustainable ingredients is often not well-established. This can lead to increased costs and complexity in production.

In addition to sourcing issues, there is an ongoing need for transparent and traceable supply chains that ensure the sustainable practices of raw material providers. Without clear certification and tracking mechanisms, manufacturers may struggle to validate the sustainability of the materials they procure. Moreover, the reliance on specific crops for bio-based raw materials raises concerns about land use and food security, further complicating the pursuit of sustainability in EVA production. Addressing these challenges will require innovative approaches and collaborations that prioritize both environmental responsibility and economic viability.

The evaluation of the carbon footprint in EVA rubber manufacturing reveals a critical contrast between traditional and sustainable practices. According to a report by the International Union of Pure and Applied Chemistry (IUPAC), traditional EVA production contributes approximately 2.5 tons of CO2 emissions for every ton of EVA manufactured. This high carbon output is attributed to the extensive use of fossil fuels and energy-intensive processes.

Conversely, sustainable EVA rubber manufacturing aims to significantly lower this environmental impact. Utilizing renewable energy sources can reduce carbon emissions by nearly 60%, as highlighted in the Global Sustainable Production Report 2022. Moreover, innovations such as bio-based feedstocks and advanced recycling technologies are becoming more prevalent, further decreasing the carbon footprint. Data from the American Chemical Society indicates that adopting these sustainable practices can lead to a net reduction of over 1.5 tons of CO2 emissions per ton of EVA produced. This shift not only fosters environmental responsibility but also positions manufacturers to meet the growing market demand for eco-friendly products.

As the world increasingly prioritizes sustainability, advancements in EVA (Ethylene Vinyl Acetate) rubber recycling are playing a crucial role in driving the circular economy. These technological innovations not only enhance the material's recyclability but also enable manufacturers to reduce waste significantly. By integrating efficient recycling processes, businesses can reclaim EVA rubber from old products and reintroduce it into the production cycle, effectively minimizing the reliance on virgin materials.

One effective tip for companies looking to embrace this shift is to invest in modern recycling technologies that can efficiently break down EVA into its core components. This allows manufacturers to create high-quality recycled material, thereby reducing costs and energy consumption associated with new material production. Additionally, companies should foster partnerships with recycling firms to establish robust take-back schemes, encouraging customers to return used products.

Another practical approach is adopting circular economy practices by designing products with recyclability in mind. Manufacturers should prioritize creating EVA products that are easy to disassemble and recycle, which can enhance the overall lifecycle of the material. Engaging consumers in this process through education about proper disposal methods can further support the transition to a more sustainable future.

The global market for children's footwear is projected to experience substantial growth, with an estimated size of $500.83 billion in 2025, expanding to $863.21 billion by 2032, marking a compound annual growth rate (CAGR) of 7.86%. This trend underscores a significant consumer shift towards eco-friendly materials, aligning with the rising demand for sustainable EVA rubber products. As environmentally conscious choices become a priority, sustainable manufacturing practices in the footwear industry are increasingly essential.

In parallel, the hot melt adhesive market is expected to grow from an estimated $9.14 billion in 2024 to over $17.03 billion by the end of 2037. This increase is indicative of a broader demand for efficient bonding solutions in sustainable manufacturing, thereby enhancing the appeal of eco-friendly footwear products. Furthermore, the unique materials market for footwear, segmented by types such as rubber and polyurethane, is also set to expand, reflecting a consumer preference for innovative and sustainable materials. The push for comfort, convenience, and sustainability continues to shape the evolving landscape of the footwear market, reinforcing the importance of EVA rubber innovations in driving this change.