In the rapidly evolving electronics industry, the protection of sensitive components from electrostatic discharge (ESD) is crucial. ESD Shielding Bags have emerged as an indispensable solution, safeguarding electronic devices during storage and transportation. According to a report by the ESD Association, an estimated 30% of product failures in the electronics sector are directly attributed to ESD damage. This alarming statistic underscores the necessity for robust protective measures, particularly in environments where static electricity can accumulate, such as manufacturing and assembly facilities. ESD Shielding Bags not only prevent the build-up of static electricity but also provide a physical barrier against environmental factors. With the global ESD protection market projected to reach $4.2 billion by 2027, the importance of these specialized bags is increasingly recognized as a vital component in maintaining product integrity and prolonging the lifespan of electronic goods. Their effective use is fundamental for any business aiming to uphold high standards of quality and reliability in today's competitive landscape.

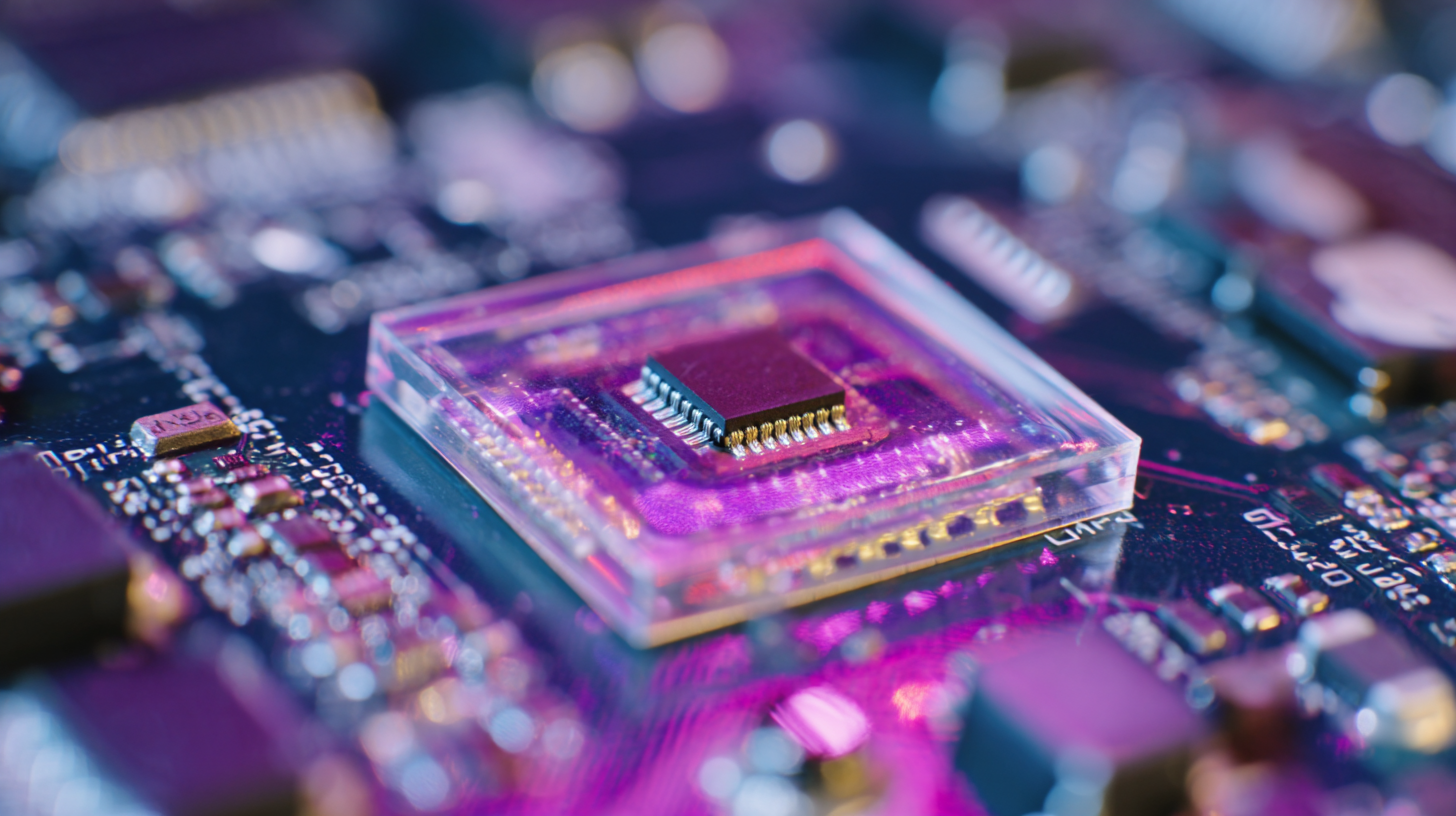

Electrostatic discharge (ESD) poses a significant threat to electronic components, and ESD shielding bags are essential tools in preventing damage from such discharges. These specialized bags are designed to contain and dissipate electrical charges, safeguarding sensitive components during storage and transportation. Made from materials that provide a conductive shield against static electricity, ESD shielding bags minimize the risk of unexpected discharges that could lead to component failure or performance issues.

The role of ESD shielding bags goes beyond mere protection; they are also instrumental in maintaining the integrity of the supply chain. By ensuring that electronic components remain shielded from static electricity, manufacturers and distributors can provide a higher assurance of quality to their customers. Furthermore, the use of these bags in production environments helps instill best practices for handling and storing electronic devices, promoting a culture of safety and responsibility that is crucial in today's technology-driven market.

| Attribute | Description | Importance |

|---|---|---|

| Material Type | Conductive polyethylene | Prevents static electricity build-up |

| Thickness | 50-100 microns | Provides optimal protection without compromise |

| ESD Rating | 10^6 to 10^9 ohms | Ensures safe handling of sensitive components |

| Size Variability | Available in various sizes | Flexibility for different electronics packaging needs |

| Transparency | Semi-transparent options available | Allows visual inspection of contents |

| Reusability | Some types are designed for multiple uses | Cost-effective for frequent users |

Electrostatic Discharge (ESD) poses a significant threat to electronic components, leading to considerable costs associated with damage and failure. Recent industry statistics reveal that ESD-related incidents account for an alarming percentage of failures in electronic manufacturing. In fact, research indicates that the industry experiences losses of approximately $5 billion annually due to ESD events. This highlights the critical need for effective protection measures to mitigate such risks.

The prevalence of ESD damage underscores the importance of utilizing ESD shielding bags for the storage and transport of sensitive electronic devices. These bags are specifically designed to dissipate static electricity and protect components from potential ESD damage. By employing ESD shielding bags, companies can significantly reduce the likelihood of costly damage, ultimately safeguarding their investments and ensuring product reliability. As the industry continues to evolve, understanding and implementing proper ESD protection strategies is essential for maintaining operational efficiency and minimizing financial losses.

Electrostatic Discharge (ESD) shielding bags play a crucial role in protecting electronic components from damage caused by static electricity. These bags are designed using specialized materials that prevent the buildup of electrostatic charges, ensuring the safe transport and storage of sensitive devices. Understanding the types of ESD shielding materials is essential for selecting the right bag for specific applications. Common materials include polyethylene, which can be formulated with conductive layers, and innovative fabrics reinforced with conductive polymers. These materials effectively dissipate static charges, minimizing risk during handling.

Recent developments in the EMI shielding market highlight the importance of advanced materials in enhancing protection against electromagnetic interference, paralleling the requirements of ESD shielding. For instance, conductive fabrics and polymer composites are being explored for their electromagnetic shielding effectiveness (EMSE). As manufacturers invest in research and innovation, the effectiveness of ESD shielding bags continues to improve, ensuring they can meet the growing demands of various industries, particularly as the electronics market expands and becomes more sophisticated. Understanding these materials not only supports better product choices but also drives the evolution of protective technologies in electronics.

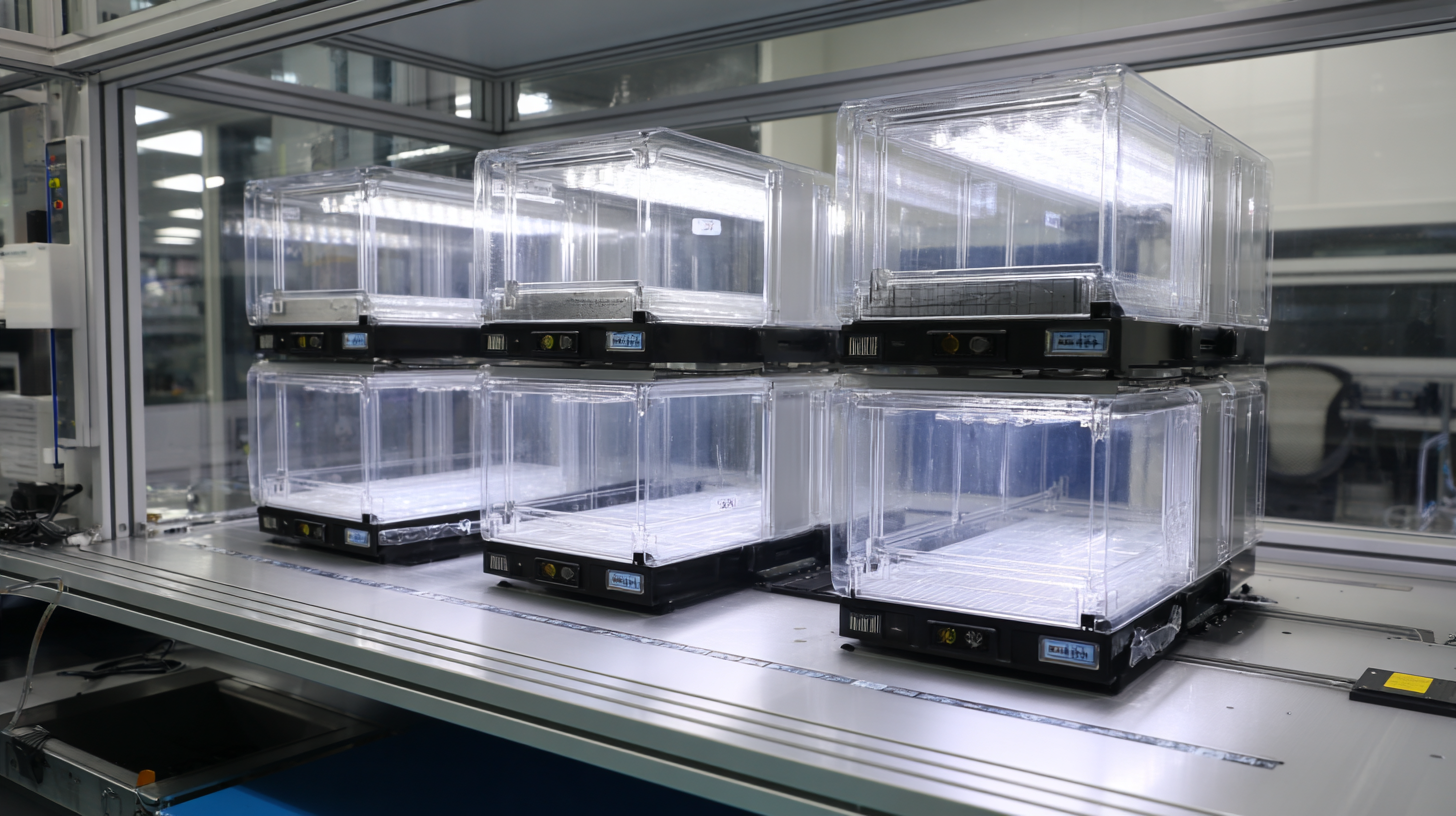

When it comes to storing electronics, implementing effective ESD (Electrostatic Discharge) shielding solutions is crucial. The primary purpose of ESD shielding bags is to protect sensitive components from static electricity, which can cause irreversible damage. To ensure maximum protection, it is essential to choose the right type of ESD bag that suits specific electronic components. For instance, metal-in bags provide excellent shielding for high-sensitive devices, while non-static dissipative bags are suitable for less sensitive items.

Tips: Always ensure the ESD shielding bags are intact and free from any punctures or tears before use. Additionally, label the bags with relevant information, such as the component type and date of storage, to streamline inventory management.

Proper storage practices also play a significant role in safeguarding electronics. Avoid placing ESD bags on surfaces that may generate static, such as plastic or vinyl. Instead, use anti-static mats or shelves. Furthermore, store the bags in a controlled environment—preferably in areas with low humidity and temperature fluctuations—to further reduce the risk of static buildup and damage to the electronics.

Tips: It’s beneficial to keep a record of all stored items and their storage conditions, allowing for easier tracking and maintenance of important electronic components.

When it comes to protecting sensitive electronic components from electrostatic discharge (ESD), understanding regulatory standards and compliance is crucial. Various standards such as ANSI/ESD S20.20 and IEC 61340 provide guidelines for ESD control, ensuring that organizations implement effective measures to minimize the risk of damage during handling and transport. Compliance with these regulations not only safeguards valuable equipment but also helps businesses avoid costly downtimes and repairs linked to ESD-related failures.

Tips: Implement regular training sessions for employees to ensure they understand the importance of ESD protection and the specific compliance requirements for your industry. Additionally, consider conducting routine audits of your ESD control measures to ensure ongoing adherence to established standards.