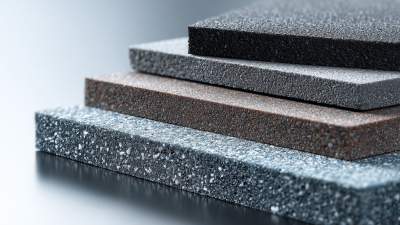

The use of Black Eva Sheet has been gaining traction across various industries due to its unique properties and versatility. According to a recent market analysis by Grand View Research, the global EVA (ethylene-vinyl acetate) market is expected to reach USD 9.3 billion by 2025, highlighting the increasing demand for innovative materials in sectors such as automotive, packaging, and construction.

Black Eva Sheet, known for its lightweight, durable, and chemically resistant characteristics, is particularly favored in applications ranging from cushioning and insulation to impact-resistant packaging solutions. Furthermore, the growing emphasis on sustainable practices has led to a significant uptick in the adoption of eco-friendly materials like EVA, further cementing the relevance of Black Eva Sheet in the modern landscape. As industries continue to explore innovative applications, understanding the strategic advantages of integrating Black Eva Sheet will be crucial for enhancing product performance and sustainability.

Black Eva Sheet, known for its lightweight, durable, and chemically resistant characteristics, is particularly favored in applications ranging from cushioning and insulation to impact-resistant packaging solutions. Furthermore, the growing emphasis on sustainable practices has led to a significant uptick in the adoption of eco-friendly materials like EVA, further cementing the relevance of Black Eva Sheet in the modern landscape. As industries continue to explore innovative applications, understanding the strategic advantages of integrating Black Eva Sheet will be crucial for enhancing product performance and sustainability.

The innovative use of black EVA (Ethylene Vinyl Acetate) sheets in packaging solutions is transforming industries seeking lightweight, durable, and versatile materials. According to a report by Allied Market Research, the global EVA market is projected to reach $9.7 billion by 2025, with a significant portion driven by its applications in packaging. Black EVA sheets, specifically, offer excellent cushioning properties, making them ideal for protective packaging. Their ability to absorb shocks while being lightweight reduces shipping costs and minimizes packaging waste.

Additionally, black EVA sheets can enhance product visibility through custom shapes and designs, allowing brands to create unique packaging that stands out while adhering to sustainability goals. A study by Grand View Research highlights that the demand for eco-friendly packaging is expected to grow at a CAGR of 5.3% from 2021 to 2028. With black EVA sheets being easily produced with recyclable materials, they are increasingly favored for retail packaging, leading to a more sustainable approach in industries such as electronics, cosmetics, and sensitive goods. This shift not only meets consumer demand for sustainable practices but also complies with evolving packaging regulations worldwide.

| Application Area | Description | Benefits |

|---|---|---|

| Packaging | Used for cushioning fragile products and preventing damage during shipping. | Lightweight, durable, and excellent shock absorption. |

| Footwear | Insoles and shoe soles made from black EVA provide comfort and support. | Enhanced cushioning, waterproof, and easy to clean. |

| Sports Equipment | Used in mats and padding for various sports to improve safety. | Effective shock absorption and slip resistance. |

| Construction | Used as a moisture barrier and protective padding. | Durability and resistance to wear and tear. |

| Toys | Soft and safe material used in various toy designs. | Non-toxic, lightweight, and flexible. |

Black EVA (Ethylene-Vinyl Acetate) sheets are gaining traction in various industries, particularly for their role in addressing environmental challenges in manufacturing. According to a report by Grand View Research, the global EVA market size was valued at USD 7.04 billion in 2021 and is expected to expand at a CAGR of 6.1% from 2022 to 2030. One of the key environmental benefits of black EVA sheets is their recyclability; they can be reprocessed and repurposed, reducing waste and conserving resources. As manufacturers strive for sustainability, integrating black EVA sheets into production processes not only mitigates the carbon footprint but also enhances product durability.

Tip: When selecting black EVA sheets for manufacturing, consider those that have been certified for their eco-friendly properties. Look for eco-labels such as ISO 14001, which ensures that the products meet international environmental management standards.

Furthermore, black EVA sheets exhibit excellent resistance to UV radiation and harsh weather conditions, making them ideal for outdoor applications. The ability to maintain structural integrity over time means less frequent replacements, leading to lower resource consumption and waste. Industry experts predict that the adoption of sustainable materials like black EVA will significantly contribute to the circular economy, with a report by the Ellen MacArthur Foundation highlighting that transitioning to such materials could reduce global annual greenhouse gas emissions by 5.7 billion tons by 2030.

Tip: Collaborate with suppliers who prioritize sustainability in their sourcing and production practices. This approach not only ensures you receive high-quality materials but also contributes to a healthier planet.

In the construction industry, safety is paramount, and innovative materials like black EVA sheet are making significant strides in enhancing workplace safety. Known for its excellent shock-absorption properties and durability, black EVA sheet provides an effective solution for reducing the risk of slips and falls on construction sites. When utilized as flooring or protective coverings, this material creates a non-slip surface that promotes worker stability, even in wet or hazardous conditions.

Moreover, black EVA sheet is resistant to weather elements, making it ideal for outdoor construction projects where exposure to moisture and UV rays can pose risks. By incorporating this material into construction applications, companies can ensure a safer working environment while simultaneously extending the longevity of their build-out surfaces. Additionally, its lightweight and flexible nature makes installation straightforward, allowing for quick deployment without compromising on safety features. As the construction industry continues to seek out advanced materials, black EVA sheet stands out as a practical choice for enhancing safety and efficiency on job sites.

The use of Black Eva Sheet in automotive interior design is gaining traction due to its unique properties, including lightweight, flexibility, and exceptional durability. According to a study by Markets and Markets, the automotive interior materials market is projected to grow from $100 billion in 2020 to over $130 billion by 2025, with the demand for lightweight and eco-friendly materials like EVA playing a key role in this expansion.

Black Eva Sheet’s closed-cell structure not only provides thermal insulation but also enhances sound absorption, making it a favored choice for manufacturers aiming to improve the comfort and luxury of vehicle interiors. The automotive industry is increasingly focusing on weight reduction to enhance fuel efficiency, and Black Eva Sheet's lightweight nature contributes significantly to achieving this goal. Furthermore, its resistance to UV radiation and moisture positively impacts the longevity of interior fittings, thus aligning with the industry's sustainability goals.

With an upward trend in the adoption of premium materials driven by evolving consumer preferences, Black Eva Sheet is positioned to become a staple in automotive interior design, offering a blend of aesthetic appeal and functional benefits that meets modern automotive demands.

The black EVA sheet has emerged as a versatile material with significant applications in health and wellness industries. Its lightweight nature, combined with superior cushioning and shock absorption properties, makes it ideal for creating supportive products ranging from medical footwear to ergonomic mats. According to a report by Grand View Research, the global orthopedic footwear market is projected to reach $6.45 billion by 2026, highlighting the increasing demand for innovative materials like black EVA in developing comfortable and protective footwear solutions.

Moreover, in the wellness sector, black EVA sheets are increasingly used in yoga mats and fitness equipment. The material’s closed-cell structure not only provides a non-slip surface, which enhances stability during exercises, but also makes it resistant to moisture and easy to clean – essential factors for maintaining hygiene in fitness environments. A study by IBISWorld indicates that the global yoga market has been growing at an annual rate of 9.8%, correlating with the rise in production and consumption of quality yoga mats made from materials such as black EVA. These characteristics make black EVA not only a practical material choice but also a key player in promoting health and wellness across various sectors.