In today's fast-paced electronics production environments, ensuring the safety and integrity of sensitive components is paramount. With reports from the ESD Association indicating that electrostatic discharge (ESD) events can contribute to billions of dollars in product losses each year, it becomes essential for manufacturers to implement effective protective measures. Among these, ESD Shielding Bags have emerged as a critical tool in safeguarding electronic parts from potentially damaging charges. These specialized bags not only offer a reliable barrier against ESD but also enhance product handling and storage efficiency, which is crucial given that nearly 70% of companies report ESD-related issues in their operations. This ultimate guide aims to delve into the best practices for utilizing ESD Shielding Bags, maximizing their protective potential, and ensuring optimal safety in production settings.

Electrostatic discharge (ESD) poses a significant risk to electronic components during production. Even a minor discharge can lead to irreversible damage, compromising the functionality and reliability of sensitive devices. Understanding ESD begins with recognizing that static electricity can accumulate on the surfaces of components, tools, and even personnel, creating a potential for discharge when two differing charge potentials come into contact. In production environments, the need for an effective management strategy is paramount to safeguard the integrity of electronic products.

One of the best practices for mitigating ESD risks is the use of ESD shielding bags. These specially designed bags are made from materials that prevent static buildup and protect against harmful discharges. When electronic components are stored or transported in ESD shielding bags, they remain insulated from external static charges, thereby reducing the likelihood of damage during handling. Moreover, implementing a comprehensive ESD control program that includes proper training for personnel and the use of grounding equipment along with shielding bags can create a safer production environment. By prioritizing ESD protection, manufacturers can ensure the longevity and reliability of their electronic products.

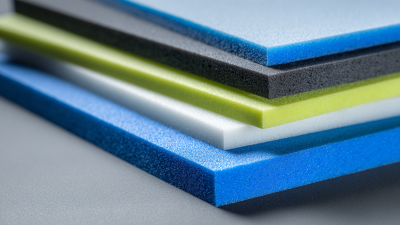

When it comes to selecting the right ESD shielding bags for optimal electronics protection, understanding the various types available is crucial. ESD shielding bags come in different materials and designs, each serving a specific purpose. The most common types include static shielding bags, plain conductive bags, and antistatic bags. Static shielding bags provide a protective layer that prevents electrostatic discharge while allowing for visibility of the contents. They are ideal for sensitive electronics in transit or storage, where exposure to static electricity poses a significant risk.

Plain conductive bags, on the other hand, are designed to prevent static buildup and are typically made from a plastic material that is infused with conductive particles. These bags are best suited for non-sensitive components that require basic protection. Lastly, antistatic bags are a more cost-effective solution, offering protection against static electricity without the shielding properties of the other two types. They are suitable for everyday use with less sensitive items. When choosing the right ESD shielding bag, consider the level of protection needed based on the sensitivity of your electronics and the environment in which they will be handled.

| Type of ESD Shielding Bag | Material | ESD Protection Level | Size Range (inches) | Use Case |

|---|---|---|---|---|

| Metalized Static Shielding Bag | Polyethylene with Metal Layer | Class 0-1 (up to 10^6 Ohms) | 3" x 5" to 12" x 18" | Sensitive Electronics Storage |

| Static Shielding Bag | Polyethylene | Class 2 (up to 10^9 Ohms) | 5" x 7" to 18" x 24" | Component Shipping |

| Pink Poly Bag | Polyethylene with Anti-Static Properties | Class 3 (up to 10^11 Ohms) | 4" x 6" to 24" x 36" | General Purpose Packaging |

| Conductive Bags | Polyethylene with Conductive Additives | Class 0 (less than 10^4 Ohms) | 3" x 5" to 36" x 48" | Secure Storage of ICs |

When working in production environments that handle sensitive electronic components, utilizing ESD shielding bags can significantly reduce the risk of electrostatic discharge, which can damage or destroy critical devices. To use these bags effectively, start by ensuring they are properly rated for the application. Look for bags that meet the necessary ESD standards, such as MIL-PRF-81705 or ANSI/ESD S541, to confirm they provide adequate protection. Additionally, it's crucial to check the integrity of the bags before each use; any damage can compromise their shielding capabilities.

Another best practice involves maintaining a controlled environment free from ESD hazards. This includes ensuring that work surfaces are grounded and utilizing wrist straps or ankle straps when handling electronic components. When placing items in ESD shielding bags, avoid any contact with the inside of the bags, as oils or contaminants from hands can reduce their effectiveness. Finally, train staff on the importance of ESD protection and the proper handling techniques of ESD shielding bags to foster a culture of safety and awareness within the production process. By implementing these practices, organizations can enhance their electronics protection strategies significantly.

When working with ESD (Electrostatic Discharge) shielding bags, proper maintenance is crucial to ensure their effectiveness and longevity. According to a report by the ESD Association, over 30% of electronics failures in production environments are attributed to ESD damage. To combat this pervasive issue, it is essential to follow best practices in the handling and storage of ESD shielding bags. Regularly inspecting bags for signs of damage or wear can significantly reduce the risk of ESD events.

Moreover, the performance of ESD shielding bags can be enhanced by storing them in a controlled environment, away from direct sunlight and extreme temperatures. The International Electrotechnical Commission (IEC) recommends that shielding bags should be kept in a humidity-controlled area to prevent moisture buildup, which can reduce their shielding effectiveness. Using appropriate labeling and ensuring bags are used within their specified shelf life can also contribute to optimal performance. By adhering to these maintenance tips, companies can enhance the reliability of their electronic components, ultimately reducing costly production downtime and failures associated with ESD.

In modern production environments, the importance of implementing effective ESD (Electrostatic Discharge) control measures cannot be overstated. ESD can cause significant damage to sensitive electronic components, leading to costly downtimes and repairs. One of the most efficient methods to mitigate ESD risks is through the use of ESD shielding bags. These specialized bags are designed to protect electronic devices from electrostatic charges during handling and transportation, ensuring that production processes remain uninterrupted and efficient.

Adopting ESD shielding bags as part of a comprehensive ESD control strategy involves more than just using the right packaging. It requires training personnel on proper handling techniques, as even minor mishandling can negate the benefits of ESD protection. Furthermore, production facilities should conduct regular audits of their ESD control measures, including checking the integrity and functionality of the shielding bags used. Ensuring that all personnel understand these measures is crucial for the long-term protection of electronic components within production environments, ultimately leading to improved product reliability and customer satisfaction.