In the realm of material science and design, mastering the properties of EVA (Ethylene Vinyl Acetate) material is becoming increasingly essential for innovative projects across various industries. Recent industry reports indicate that the global EVA market is expected to reach $6.4 billion by 2026, driven by its versatile applications in packaging, footwear, and automotive sectors. The unique characteristics of EVA, such as its excellent elasticity, transparency, and resistance to UV light, make it a preferred choice for product developers aiming to combine functionality with aesthetics.

This comprehensive tutorial aims to equip you with the knowledge and techniques necessary to harness the full potential of EVA material, enabling you to push the boundaries of innovation in your next project. Whether you are a seasoned professional or a newcomer in the field, understanding EVA material properties can significantly enhance your design effectiveness and market competitiveness.

EVA (Ethylene-Vinyl Acetate) is a copolymer that has gained popularity across various industries due to its unique composition and versatile characteristics. Composed of ethylene and vinyl acetate, the material combines the toughness and flexibility of polyethylene with the elasticity of rubber. This results in a lightweight material that exhibits excellent shock absorption, UV resistance, and adaptability to various temperatures. According to a recent report by the Research and Markets, the global EVA market is projected to reach USD 8.79 billion by 2025, indicating an increasing demand driven by sectors such as packaging, automotive, and consumer goods.

In addition to its impressive physical properties, EVA is also known for its enhanced adhesion properties, making it an ideal choice for applications like adhesives and sealants. A study published in the Journal of Applied Polymer Science highlighted EVA's ability to retain strength and flexibility even at low temperatures, which is crucial for products subject to varying environmental conditions. Furthermore, the material's compatibility with various fillers and additives allows for tailored properties to meet specific project requirements, making it a favorite among engineers and product designers seeking innovative solutions in their work. The versatility of EVA continues to pave the way for novel applications, establishing it as a material of choice for demanding projects.

EVA (Ethylene Vinyl Acetate) material has gained significant attention in various innovative applications due to its unique properties. Its lightweight, flexibility, and excellent impact resistance make it an ideal choice for many industrial designs. As we witness the burgeoning demand for sustainable practices, understanding the key properties of EVA is essential, especially as the market for bio-balanced EVA is projected to grow substantially from $0.5 million in 2022 to $1.2 million by 2030, with a compound annual growth rate of 10.7%.

When integrating EVA into your projects, consider its superior shock absorption and thermal stability, which are particularly beneficial in manufacturing sports equipment, automotive parts, and packaging materials. Tips for enhancing EVA performance include optimizing the material blend to increase elasticity and conducting thorough testing under various conditions to ensure durability.

Furthermore, EVA's compatibility with other materials allows for innovative combinations, enhancing its application scope. As organizations move towards a circular economy, such as solar panel recycling plants, leveraging EVA's properties for energy-efficient solutions will be crucial. Emphasizing its adaptability could set the stage for new groundbreaking projects in your industry.

In recent years, the application of ethylene vinyl acetate (EVA) has gained momentum across various industries due to its unique properties that often set it apart from other polymers. A comparative analysis reveals that while materials like polyolefin exhibit good impact absorption properties, EVA stands out with its flexibility and toughness, making it ideal for applications such as sports mouthguards and protective gear.

When considering materials for innovative projects, be sure to evaluate the specific demands of your application. For instance, if impact resistance is crucial, take advantage of EVA's superior shock absorption capabilities. Additionally, the self-healing properties of newer EVA formulations can offer long-term benefits, enhancing product longevity and performance.

Tip: When selecting a polymer, consider not only its immediate performance attributes but also how it can be modified or enhanced through chemical processes like copolymerization. This can provide additional functionalities such as biodegradability or enhanced thermal stability, broadening the scope of your project’s potential applications.

When embarking on a project that utilizes EVA (Ethylene Vinyl Acetate) material, sourcing high-quality materials is crucial. According to a recent market analysis by Grand View Research, the global EVA market is projected to reach USD 8.0 billion by 2025, driven by its extensive applications across industries such as footwear, electronics, and automotive. This growing demand highlights the importance of selecting EVA materials that not only meet project specifications but also ensure durability and performance.

To source quality EVA material, consider partnering with manufacturers that adhere to industry standards and certifications. The American Chemistry Council emphasizes that compliance with environmental regulations and material testing is vital for ensuring product quality. It is recommended to request detailed technical data sheets from suppliers, which should include information on tensile strength, elasticity, and thermal properties. By focusing on reputable suppliers and conducting thorough due diligence, you can enhance the reliability of your project outcomes while taking full advantage of the unique properties of EVA.

| Property | Description | Typical Values | Applications |

|---|---|---|---|

| Density | Mass per unit volume of the EVA material | 0.93 - 1.00 g/cm³ | Footwear, packaging |

| Hardness | Resistance to deformation and indentation | Shore A 40 - 80 | Sports equipment, insulation |

| Elongation at Break | Stretchability before rupture | 200% - 800% | Molded parts, seals |

| Tensile Strength | Maximum stress before failure | 10 - 25 MPa | Automotive parts, consumer goods |

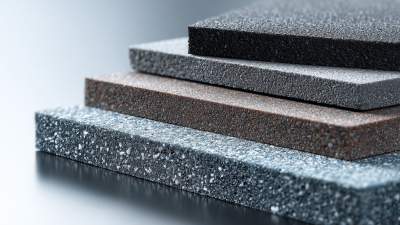

| Color | Visual appearance color options | Transparent, Colored | Design applications, art |

Exploring the innovative applications of Ethylene-Vinyl Acetate (EVA) material opens new avenues in design and manufacturing across various industries. EVA is not only favored for its excellent flexibility and impact resistance but also for its adaptability in cutting-edge projects. In the footwear sector, for instance, the use of EVA films for solar panel encapsulation signifies its versatility. These films can enhance energy efficiency while providing structural integrity in domestic and commercial applications.

Furthermore, the advent of 3D printing technology elevates the role of EVA in custom designs, particularly in crafting shoes tailored to individual foot shapes. By leveraging CAD/CAM technology, designers can create bespoke shoe lasts that ensure comfort and performance. This integration of EVA and 3D printing simplifies the manufacturing process while allowing for innovative structures like cellular designs used in mouthguards. Such applications demonstrate how EVA material not only meets functional demands but also inspires creativity in product development, paving the way for future trends in manufacturing and design.