High Density EVA Foam has gained significant attention in various industries due to its unparalleled comfort and durability. According to a recent market research report by Grand View Research, the global EVA foam market was valued at over $9 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth can be attributed to the foam's versatility in applications ranging from athletic footwear to ergonomic seating solutions.

High Density EVA Foam has gained significant attention in various industries due to its unparalleled comfort and durability. According to a recent market research report by Grand View Research, the global EVA foam market was valued at over $9 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth can be attributed to the foam's versatility in applications ranging from athletic footwear to ergonomic seating solutions.

High Density EVA Foam, in particular, offers enhanced shock absorption and resilience, making it ideal for products that require both comfort and longevity. As manufacturers increasingly prioritize consumer demand for quality materials, understanding how to maximize the benefits of High Density EVA Foam becomes crucial for designers and engineers seeking to create innovative, high-performance products.

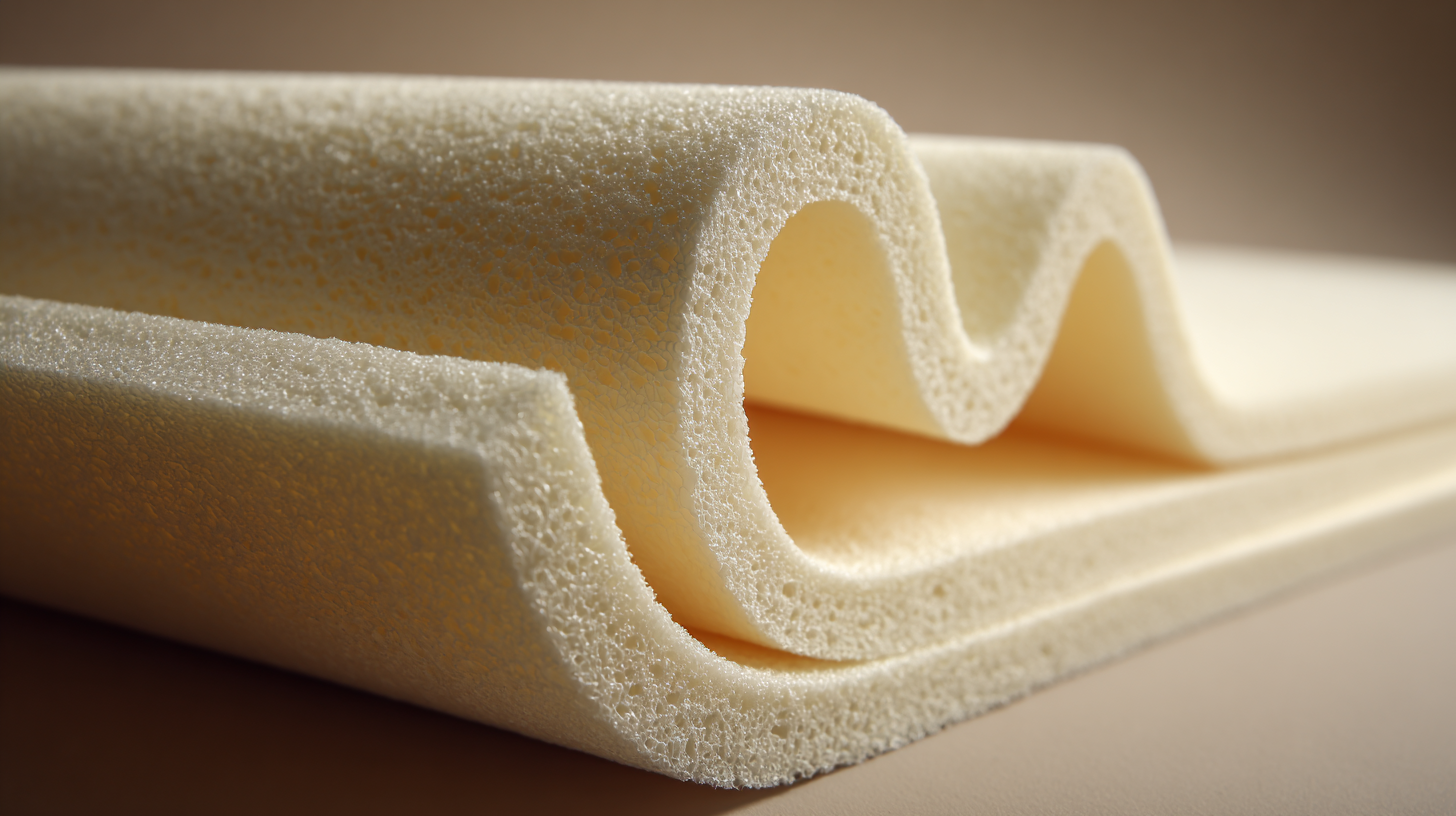

High-density EVA (Ethylene Vinyl Acetate) foam is renowned for its exceptional properties that make it an ideal choice for various applications, from footwear to cushioning materials. One of the standout characteristics of high-density EVA foam is its impressive resilience, which allows it to withstand repeated stress and impact without losing its shape. This makes it particularly beneficial in environments where durability is paramount, such as in sports and outdoor equipment. Additionally, the closed-cell structure of high-density EVA foam provides excellent water resistance, further enhancing its suitability for diverse applications.

Moreover, high-density EVA foam offers significant benefits in terms of comfort. Its soft yet supportive nature helps distribute weight evenly, reducing pressure points and enhancing the overall user experience. The foam is also lightweight, adding to its comfort, particularly in products designed for prolonged wear. The versatile nature of high-density EVA foam allows manufacturers to tailor its properties—such as firmness and cushioning—depending on the intended use, making it a preferred material across various industries. Understanding these properties enables users to maximize comfort and durability, ensuring that products built with high-density EVA foam meet and exceed expectations.

| Property | Description | Benefits | Best Practices |

|---|---|---|---|

| Density | High density EVA foam typically ranges from 30 to 90 kg/m³. | Increases support and enhances durability. | Choose the right density for your application. |

| Compression Resistance | Ability to withstand deformation under load. | Provides long-lasting comfort without flattening. | Ensure proper thickness to optimize performance. |

| Water Resistance | Resistant to moisture, preventing mildew and odor. | Ideal for outdoor and high-humidity applications. | Use in environments where moisture exposure is high. |

| Shock Absorption | Effectively absorbs impact forces. | Helps reduce fatigue during prolonged use. | Combine with ergonomic designs for best results. |

| Temperature Resistance | Maintains performance in various temperature ranges. | Suitable for both hot and cold environments. | Consider in applications with extreme temperatures. |

High-density EVA foam is an incredibly versatile material, gaining traction in various industries due to its unique combination of comfort and durability. In the sports and fitness sector, high-density EVA foam is widely utilized in mats, padding, and equipment handles. This material provides excellent shock absorption and cushioning, ensuring safety and enhancing performance during workouts. Additionally, the non-slip characteristics of EVA foam give users the confidence they need while exercising, significantly reducing the risk of injuries.

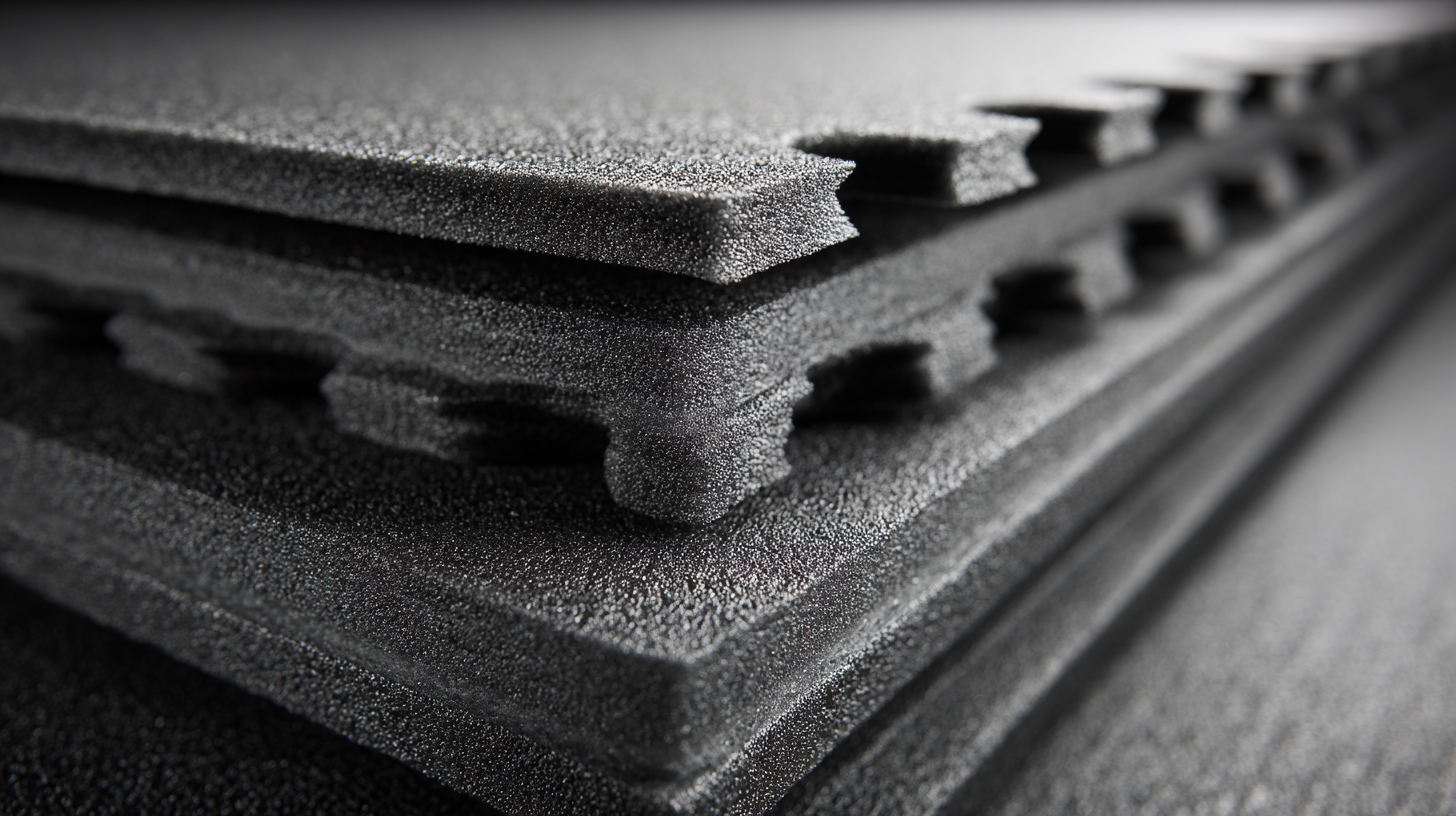

Another key application of high-density EVA foam is in the footwear industry. Many shoe manufacturers are turning to this material for insoles and outsoles, as it offers superior cushioning while maintaining structural integrity. The lightweight nature of EVA foam also contributes to shoes that feel comfortable during long hours of wear, making it ideal for both athletic and casual footwear. Similarly, in the packaging industry, high-density EVA foam is employed to protect fragile items during transportation, providing robust cushioning that resists compression over time. Such diverse applications highlight the adaptability of high-density EVA foam across different sectors.

When selecting the right density of EVA foam, it's essential to understand how density impacts both comfort and durability. According to a report by Research and Markets, the global market for EVA foam is expected to reach $1.5 billion by 2025, highlighting its widespread application in various industries from footwear to packaging. The density of EVA foam can range from 30 kg/m³ to 300 kg/m³, with varying levels of firmness and resilience. Higher density EVA foams, typically above 80 kg/m³, offer superior durability while providing support that is crucial for applications like athletic footwear and high-impact mats.

To ensure optimal performance, consider the specific use case. For instance, if the foam will be subjected to frequent compression, such as in gym mats or orthopedic products, selecting a foam density of 100 kg/m³ or above is advisable. Industry specifications indicate that higher densities provide not only better shock absorption but also enhanced resistance to deformation. According to the International Journal of Material Science, EVA foam with a density exceeding 120 kg/m³ demonstrated a 20% increase in longevity compared to lower-density options, making it an economical choice for long-term use. Understanding these dynamics will enable buyers to make informed decisions that balance comfort, durability, and cost-effectiveness.

High-density EVA foam is increasingly popular due to its exceptional comfort and durability. To enhance comfort with this material, one effective technique is the layering approach. By using multiple layers of high-density EVA foam, you can customize the firmness and support levels. The added layers allow for better compression, adapting to the body's contours while maintaining its structural integrity. This results in a more personalized and comfortable experience, especially for applications like mats, cushions, and footwear.

High-density EVA foam is increasingly popular due to its exceptional comfort and durability. To enhance comfort with this material, one effective technique is the layering approach. By using multiple layers of high-density EVA foam, you can customize the firmness and support levels. The added layers allow for better compression, adapting to the body's contours while maintaining its structural integrity. This results in a more personalized and comfortable experience, especially for applications like mats, cushions, and footwear.

Tips for maximizing comfort also include ensuring the foam is correctly sized for its intended use. For instance, when using EVA foam for seating, consider the thickness and density that align with the user's preferences. A thicker foam might provide extra cushioning, while a firmer variant can enhance support. Additionally, adding a soft fabric cover can improve the tactile experience, making long periods of use much more enjoyable.

Another technique to enhance comfort is the integration of ergonomic shapes and designs. Shaping the foam to conform to the natural curves of the body can significantly reduce pressure points. This principle is often applied in products like gaming chairs and mattresses, where prolonged use might lead to discomfort. By focusing on ergonomics, you ensure that high-density EVA foam not only remains durable but also provides unparalleled comfort.

To extend the lifespan of EVA foam products, regular maintenance is essential. One key practice is to ensure proper cleaning. Use a damp cloth and mild soap to wipe down the surface, removing dirt and grime without damaging the foam. Avoid harsh chemicals that can break down the material and lead to premature wear. It’s also vital to dry the foam thoroughly after cleaning to prevent mold or mildew from forming, especially if the foam is used in damp environments.

Additionally, proper storage plays a critical role in maintaining EVA foam's durability. Store items in a cool, dry place away from direct sunlight, as UV exposure can degrade the material over time. When not in use, consider stacking foam products or using protective covers to shield them from dust and scratches. Regular inspections for signs of wear or damage will allow for timely repairs or replacements, ensuring that your EVA foam products remain comfortable and functional for as long as possible.