The popularity of PE plastic bags in the packaging industry can be attributed to their versatility, durability, and cost-effectiveness. According to a report by Smithers Pira, the global demand for plastic packaging is projected to reach 400 million tonnes by 2024, with PE plastic bags playing a significant role in this growth. These bags are not only lightweight but also provide excellent barrier properties, making them ideal for a wide range of products, from food items to retail goods.

Moreover, PE plastic bags are preferred due to their recyclability and potential for reuse. The Flexible Packaging Association highlights that nearly 10% of flexible packaging, which predominantly includes PE materials, is recycled in the U.S. This statistic attests to the increasing awareness and willingness of consumers and industries to adopt sustainable practices. With ongoing advancements in recycling technologies and initiatives aimed at reducing plastic waste, the adoption of PE plastic bags is expected to rise.

As businesses seek effective, sustainable packaging solutions, PE plastic bags emerge as a leading choice in the market. Their ability to balance functionality with environmental considerations positions them well in an industry that is continually evolving toward sustainable practices. The future of packaging will likely hinge on the creativity and innovation surrounding materials like PE plastic bags, ensuring their relevance in the changing landscape of consumer packaging.

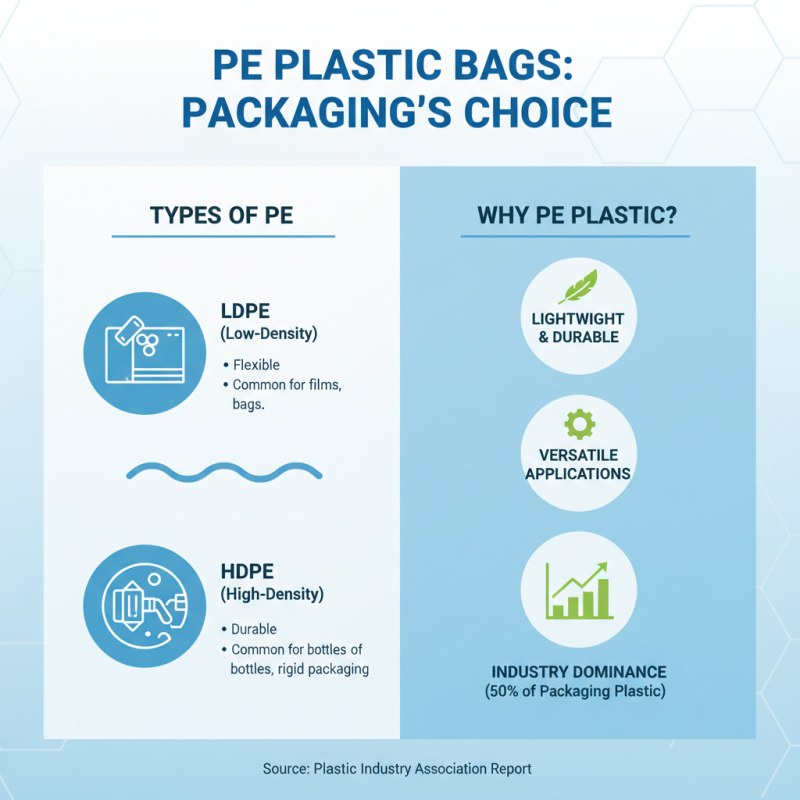

PE plastic bags, composed primarily of polyethylene, are favored in the packaging industry due to their unique characteristics and versatility. Made from either low-density polyethylene (LDPE) or high-density polyethylene (HDPE), these bags are cherished for their lightweight nature and durability. According to a report by the Plastic Industry Association, polyethylene accounts for approximately 50% of all plastic used in packaging, highlighting its dominance and preference among manufacturers.

The characteristics of PE plastic bags include excellent moisture resistance, chemical stability, and flexibility, making them suitable for a variety of applications, from retail to food packaging. They are also recyclable, which has become increasingly important in a world focusing on sustainability. Data from the Association of Plastic Recyclers demonstrate that recycling rates for polyethylene bags have improved significantly, reaching up to 20% in recent years. This not only reduces waste but also maximizes the lifecycle of the material, aligning with global initiatives aimed at minimizing environmental impact.

Moreover, the cost-effectiveness of PE bags is another reason for their popularity; they provide a low-cost packaging solution without compromising on quality. Industry research indicates that the global demand for polyethylene plastic bags is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years, underlining their continuing appeal in the packaging sector. This blend of attributes—performance, recyclability, and affordability—ensures that PE plastic bags remain a preferred choice for a wide range of packaging needs.

Polyethylene (PE) plastic bags have gained immense popularity in the packaging industry due to their numerous advantages. One of the key benefits of PE plastic bags is their durability and flexibility. These bags can withstand various weights and conditions without tearing or breaking, making them ideal for storing a wide range of products, from groceries to industrial materials. Their lightweight nature also reduces shipping costs, which is particularly advantageous for businesses looking to minimize expenses while maintaining effective packaging solutions.

Moreover, PE plastic bags are highly resistant to moisture and chemicals, providing an excellent barrier against external elements. This property is crucial for protecting sensitive products, especially in food packaging, where freshness and safety are paramount. Additionally, PE plastic bags can be recycled, contributing to more sustainable packaging practices. Many consumers are increasingly aware of environmental issues, leading to a demand for recyclable packaging options.

The combination of functionality, cost-effectiveness, and eco-friendliness makes PE plastic bags an appealing choice for both manufacturers and consumers in the ever-evolving packaging landscape.

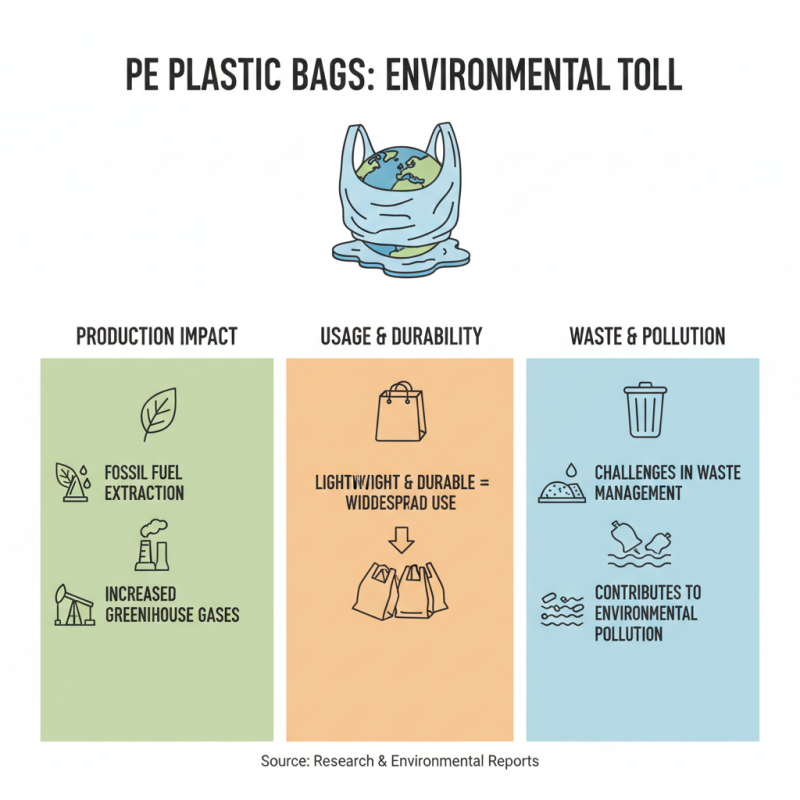

The environmental impact of using polyethylene (PE) plastic bags has sparked considerable debate in recent years, primarily due to their widespread usage and the challenges they pose in waste management. While PE bags are highly favored for their lightweight and durability, their production and disposal processes significantly contribute to environmental pollution. The manufacturing of these bags involves the extraction and processing of fossil fuels, which not only increases greenhouse gas emissions but also depletes natural resources.

Once disposed of, PE plastic bags often end up in landfills or the natural environment, where they can take hundreds of years to decompose. This durability can be a double-edged sword; while it means they can be reused multiple times, it also means that they persist in ecosystems, posing threats to wildlife. Animals can ingest or become entangled in discarded plastic, leading to severe health issues or fatalities. Additionally, when plastic breaks down into microplastics, it can enter food chains and disrupt marine and terrestrial ecosystems, raising concerns about food safety and biodiversity.

Addressing the environmental impact of PE plastic bags necessitates a shift towards more sustainable alternatives and improved waste management practices. Efforts are underway globally to reduce reliance on plastic, encouraging the use of biodegradable and compostable materials. Moreover, widespread public awareness initiatives aim to inform consumers about responsible disposal methods and the importance of reducing plastic consumption. Implementing these strategies is crucial for mitigating the negative effects of PE plastic bags on the environment while still meeting the demands of modern packaging solutions.

The PE plastic bag manufacturing industry has witnessed significant trends and innovations in recent years. Companies are increasingly adopting advanced technologies to enhance production efficiency and reduce waste. Innovations such as biodegradable additives and eco-friendly production methods are becoming more common, addressing environmental concerns while maintaining the durability and versatility that PE plastic bags offer. As a result, manufacturers can create bags that meet both consumer needs and sustainability goals.

Tips for consumers looking to choose environmentally-friendly options include checking for biodegradable labels on PE bags and opting for reusable alternatives when possible. Additionally, understanding the recycling processes in their regions helps consumers make informed choices about disposal. This knowledge not only promotes responsible usage but also supports the broader movement towards sustainability in packaging.

Another key trend is the customization of PE plastic bags. Brands are increasingly looking for ways to differentiate themselves in a competitive market, leading to innovative designs and personalized prints. This trend not only enhances brand visibility but also allows businesses to convey their values and commitments to sustainability through packaging. Embracing these trends, companies can align their practices with consumer expectations while contributing positively to the environment.

The use of polyethylene (PE) plastic bags in the packaging industry faces increasing regulatory scrutiny as governments and organizations worldwide strive for environmental sustainability. Many regions have imposed bans or restrictions on single-use plastics to combat pollution and promote the adoption of more eco-friendly alternatives. This has prompted manufacturers to innovate and explore biodegradable options or alternative materials, even as demand remains high for PE plastic bags in various applications, such as grocery and retail packaging.

Looking ahead, the future of PE plastic bags will depend significantly on compliance with emerging regulations and consumer preferences. Companies are being encouraged to adopt circular economy principles, focusing on recycling and reusing materials to reduce waste. Innovations in recycling technology and the development of biodegradable PE materials could provide pathways for the continued use of plastic bags while minimizing their environmental footprint. As businesses navigate these changes, the ongoing dialogue between regulators, manufacturers, and consumers will shape the evolution of packaging solutions, ensuring that they meet both practical needs and sustainability goals.

This bar chart illustrates the projected increase in the usage of PE plastic bags in the packaging industry from 2020 to 2025. The data indicates a steady growth trend, reflecting the ongoing popularity of PE plastic bags due to their versatility and cost-effectiveness.