In an increasingly digital world, the protection of electronic components from electrostatic discharge (ESD) has become paramount. One of the most effective solutions to safeguard sensitive devices is the use of ESD shielding bags. These specialized bags are designed to prevent the accumulation and discharge of static electricity, which can lead to irreparable damage to various electronic parts. With a myriad of options available on the market, selecting the right ESD shielding bags can be pivotal for both manufacturers and consumers alike.

The significance of ESD shielding bags cannot be overstated, particularly as electronic devices continue to shrink in size and increase in complexity. As the industry evolves, so does the need for robust ESD protection measures. A reliable shielding bag not only offers a protective barrier against static but also ensures that components are stored and transported without the risk of electrostatic interference. In this article, we will explore the top 10 ESD shielding bags that every electronics enthusiast and professional should consider, highlighting their features, benefits, and why they are essential for maintaining the integrity of modern technology.

Electrostatic Discharge (ESD) refers to the sudden flow of electricity between two objects caused by contact, an electrical short, or dielectric breakdown. This phenomenon can have disastrous effects on sensitive electronic components, leading to performance degradation or complete failure. Understanding ESD and its implications is crucial for anyone involved in the handling and manufacturing of electronic devices. Even a small charge can potentially damage microchips, circuit boards, and other integral parts, emphasizing the importance of proper ESD protection strategies.

To safeguard your electronics, utilizing ESD shielding bags is essential. These bags are designed to prevent static electricity from building up and protect your components from ESD caused by external factors. When selecting ESD shielding bags, consider factors such as the material’s conductivity, the bag's size compatibility with your components, and its overall effectiveness in shielding. For optimal protection, always store sensitive electronics in these bags during transport and storage.

Tips for maintaining ESD safety include grounding yourself before handling electronic parts, using an ESD wrist strap, and ensuring your work area is free of static-prone materials. Additionally, keep an eye out for ambient conditions—high humidity levels can help dissipate static but can also create other issues, so always check your workspace environment for ideal conditions. By implementing these practices, you can significantly reduce the risk of ESD damage to your valuable electronics.

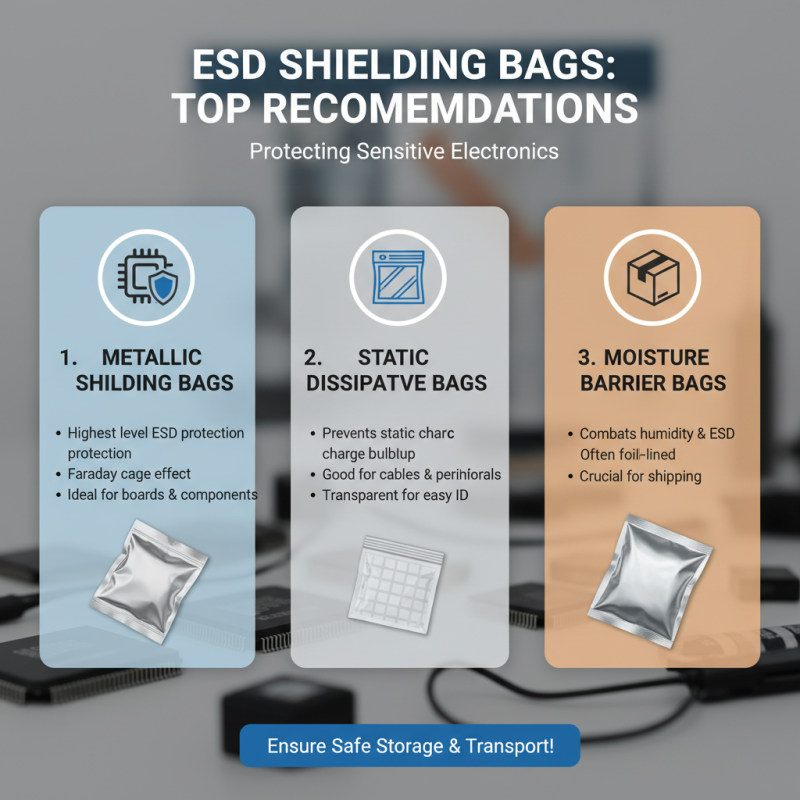

When it comes to safeguarding electronics from potential damage caused by electrostatic discharge (ESD), choosing the right type of ESD shielding bag is crucial. The market offers several options, including metallized bags, static shielding bags, and conductive bags, each designed to fulfill specific protective roles. Metallized bags, for instance, utilize a thin layer of metal to reflect electromagnetic waves, making them effective for outer packaging. Static shielding bags, on the other hand, provide a barrier to static fields and are often used for components that are sensitive to ESD. Conductive bags not only shield against ESD but also dissipate any charge, making them ideal for components that require grounding.

According to a report by the IPC (Institute for Printed Circuits), improper handling of electronic parts can cause failures valued at approximately $5 billion annually due to ESD-related damages. This statistic underscores the importance of investing in quality ESD packaging solutions. It's essential to evaluate your specific needs, such as the level of sensitivity of the components and the storage environment, before selecting a bag type.

**Tip:** Always ensure that the ESD shielding bags you choose meet the necessary industry standards for electrostatic protection, such as ANSI/ESD S20.20. Checking for certification can help you avoid potential risks associated with substandard products. Additionally, consider the bag's thickness and material composition, as these factors contribute significantly to the effectiveness of ESD protection.

| Bag Type | Size (inches) | Thickness (mil) | ESD Rating (kV) | Material |

|---|---|---|---|---|

| Anti-Static Polypropylene | 6 x 8 | 4 | 20 | Polypropylene |

| Conductive Reclosable Bags | 9 x 12 | 6 | 30 | Polyethylene |

| Metalized Static Shielding Bags | 5 x 7 | 8 | 25 | Metalized Film |

| ESD Safe Plastic Zipper Bags | 10 x 14 | 4 | 15 | Polyethylene |

| Static Shielding Oversleeves | Large | 2 | 20 | Polyester |

| Conductive Foam Bags | 7 x 9 | 10 | 35 | Foam |

| ESD Anti-Static Bubble Bags | 8 x 10 | 3 | 18 | Bubble Film |

| Reinforced ESD Bags | 12 x 16 | 9 | 30 | Heavy-duty Film |

| Clear Anti-Static Bags | 4 x 6 | 2 | 15 | Polyethylene |

| PEE (Polyester ESD Bags) | 11 x 15 | 5 | 20 | PEE Material |

When selecting ESD shielding bags, understanding key features is essential to effectively protect your electronics from electrostatic discharge. ESD bags must possess a combination of conductivity, durability, and appropriate size to accommodate various electronic components. According to the Institute of Electrical and Electronics Engineers (IEEE), improper handling of sensitive electronics can lead to a loss of performance or even complete failure in up to 30% of devices. Therefore, selecting a quality ESD bag becomes crucial.

A crucial factor to consider is the bag's material. Look for bags made from polyethylene or other conductive materials that offer excellent static dissipative properties. The thickness of the bag is also important; studies show that bags with a thickness of 3-5 mils provide better protection against physical damage and puncturing. Additionally, ensure that the bag is properly sealed to maintain its shielding effectiveness. Bags with a sealable closure or zip-lock feature can further enhance long-term protection.

Tips: Always store ESD-sensitive devices in their designated bags when not in use. This simple practice prevents accidental exposure to static and prolongs the lifespan of your electronics. Additionally, when transporting electronics, make sure that the bags are secured within a padded container to add extra layers of protection, especially during travel.

When it comes to protecting sensitive electronics from electrostatic discharge (ESD), choosing the right shielding bags is crucial. ESD shielding bags serve as a barrier against static electricity that can cause significant damage to electronic components. Here are some top recommendations for ESD shielding bags that cater to various needs, ensuring your electronics remain safe during storage and transportation.

One of the key tips when selecting ESD shielding bags is to look for materials that provide sufficient conductivity while being durable. Bags made from multiple layers of static dissipative materials are generally ideal as they help to dissipate electrical charges effectively. Additionally, consider the size of the bags relative to your components to avoid unnecessary movement inside the bag, which can generate static.

Another important tip is to ensure that the bags are properly sealed. Whether you opt for zip-lock closures or heat-sealed options, a tightly sealed bag will prevent dust and moisture from entering, further protecting your electronics. Always remember to handle the bags with care to maintain their effectiveness, and store them in a controlled environment to optimize their lifespan and reliability. By following these tips, you can select the best ESD shielding bags to safeguard your electronic devices from potential damage.

When it comes to storing sensitive electronics, employing best practices with ESD shielding bags is crucial for ensuring their longevity and functionality. First and foremost, it's important to select the right type of ESD shielding bag for your specific needs. Bags should provide ample protection against electrostatic discharge while also being compatible with the electronic components being stored. Ensure that the bags are made of high-quality materials that are designed to dissipate static electricity effectively, thereby preventing any potential damage to the delicate circuitry.

In addition to selecting appropriate bags, the way in which electronics are stored can significantly impact their protection. Always handle the items with care, wearing grounded wrist straps if available, to minimize any risk of static electricity transfer. When placing electronic components inside the bags, make sure they are clean and free from contaminants that could lead to short circuits or corrosion. Seal the bags securely to prevent exposure to moisture and dust, as these elements can also compromise the integrity of electronic devices. By following these best practices, you can enhance the durability and performance of your electronics while minimizing the risks associated with electrostatic discharge.

This chart displays the effectiveness scores of the top 10 ESD shielding bags based on their material properties and user ratings. The scores range from 1 to 100, with higher values indicating better protection against electrostatic discharge.