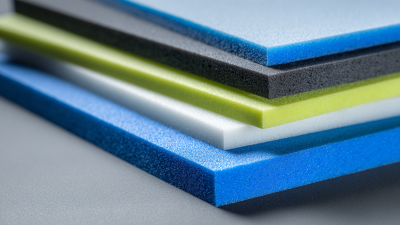

In today’s diverse industrial landscape, the versatility and practicality of Eva Foam Sheet have made it an essential material across various sectors. From packaging and construction to automotive and sports equipment, this lightweight foam offers exceptional cushioning, insulation, and water resistance, making it a preferred choice for countless applications. As industries continue to innovate and seek sustainable solutions, understanding the myriad benefits and potential uses of Eva Foam Sheet becomes increasingly important. This ultimate guide will explore the numerous applications of Eva Foam Sheet, providing insights into how it can enhance products and processes, ultimately empowering businesses to make informed decisions when incorporating this dynamic material into their operations. Whether you are a manufacturer, designer, or DIY enthusiast, this comprehensive resource will illuminate the many ways Eva Foam Sheet can be utilized effectively.

EVA foam sheets have gained immense popularity in the sports and recreational industry due to their versatile applications and numerous benefits. These lightweight, durable sheets provide exceptional shock absorption, making them an ideal choice for various sporting goods and equipment. For instance, EVA foam is commonly used in cushioning for athletic shoes, ensuring comfort and reducing the risk of injuries during rigorous activities such as running and jumping. Its flexibility also allows for the creation of custom shapes, enhancing the performance of gear like helmets and pads.

Additionally, EVA foam sheets are utilized in the production of fitness mats and flooring for gyms, as they offer excellent grip and stability during workouts. Their water-resistant properties make them perfect for aquatic sports, where they can be found in life vests, surfboards, and pool floats. The ability to manufacture these foam sheets in various colors and designs also enables brands to provide aesthetically appealing products that cater to the preferences of athletes and recreational users alike. As innovation continues, the applications of EVA foam sheets in sports and recreation are expected to expand, solidifying their status as a crucial material in this dynamic industry.

In recent years, the packaging and shipping sector has seen a significant shift towards eco-friendly materials, with Eva foam sheet emerging as a preferred choice due to its versatility and durability. According to a report by Smithers Pira, the global market for eco-friendly packaging is projected to reach approximately $500 billion by 2024, highlighting a growing trend in sustainable packaging solutions. Eva foam is lightweight and provides exceptional cushioning, which reduces breakage and damages during shipping, contributing to cost savings and enhancing customer satisfaction.

Moreover, Eva foam's water-resistant properties make it ideal for protecting goods from moisture, a critical factor given that about 25% of all products are damaged during transportation due to water exposure, as noted in the National Association of Manufacturers report. The inherent shock-absorbing qualities of Eva foam not only safeguard fragile items but also streamline the packaging process, enabling businesses to optimize their supply chain efficiency. By incorporating Eva foam into their packaging strategies, companies can not only improve product protection but also capitalize on the growing demand for sustainable, effective packaging solutions in the marketplace.

| Application Area | Benefits | Common Uses |

|---|---|---|

| Packaging | Lightweight, cushioning, shock absorption | Inner cushioning for boxes, protective wraps |

| Shipping Protection | Moisture resistance, durability | Padding for fragile items, thermal insulation |

| Custom Molds | Form-fitting, resource-efficient | Custom packaging solutions for unique products |

| Insulation | Thermal insulation, energy efficiency | Temperature-controlled shipping |

| Cost Efficiency | Reduced shipping costs due to lightweight material | Lower transportation expenses for bulk goods |

Eva foam has emerged as a versatile material in the medical and healthcare sectors, particularly in the design and production of orthotic insoles. The global market for foot orthotics is projected to see significant growth, with estimates suggesting it will reach $4.51 billion by 2025 and $7.16 billion by 2032, driven by an annual growth rate of 6.8%. This increasing demand highlights the integral role that advanced materials like Eva foam play in enhancing patient comfort and mobility.

Eva foam has emerged as a versatile material in the medical and healthcare sectors, particularly in the design and production of orthotic insoles. The global market for foot orthotics is projected to see significant growth, with estimates suggesting it will reach $4.51 billion by 2025 and $7.16 billion by 2032, driven by an annual growth rate of 6.8%. This increasing demand highlights the integral role that advanced materials like Eva foam play in enhancing patient comfort and mobility.

In the United States, the foot orthotic market itself is also on the rise, anticipated to grow from $1.32 billion in 2022 to $2.35 billion by 2030. The lightweight, durable properties of Eva foam make it an ideal choice for insole production, providing essential support and cushioning for those with various foot conditions. Its innovative applications not only address specific medical needs but also improve overall quality of life by allowing individuals to engage more freely in daily activities. Eva foam's adaptability continues to make it a critical component in developing next-generation healthcare products.

EVA foam, or ethylene-vinyl acetate foam, plays a crucial role in the construction and insulation industries due to its unique properties. One of the key advantages of EVA foam is its excellent thermal insulation capabilities. This material effectively reduces heat transfer, making it an ideal choice for energy-efficient building designs. When used in insulation applications, EVA foam not only helps maintain a stable indoor temperature but also contributes to significant energy savings, ultimately reducing heating and cooling costs over time.

In addition to its thermal properties, EVA foam is remarkably resistant to moisture, making it suitable for various environments, including those prone to humidity or exposure to water. This moisture resistance helps prevent mold growth and material degradation, thereby enhancing the longevity and durability of construction projects. Furthermore, EVA foam is lightweight and easy to work with, allowing for quick installation and adaptability in various construction applications. Whether used as underlayment, thermal barriers, or in prefabricated elements, EVA foam continues to be a preferred choice for innovative and sustainable building solutions.

Ethylene-vinyl acetate (EVA) foam plays a crucial role in automotive manufacturing and design, thanks to its unique combination of properties. Its lightweight nature significantly contributes to improving fuel efficiency while maintaining durability and strength. Manufacturers often use EVA foam in vehicle interiors for components like headliners, floor mats, and seating, enhancing comfort and noise reduction. The material's cushioning properties help absorb impact, making it an ideal choice for safety features like seat cushioning and impact-resistant panels.

In addition to comfort and safety, EVA foam provides excellent thermal insulation. This characteristic is particularly beneficial in electric and hybrid vehicles, where temperature regulation of battery systems is vital. Additionally, the material is resistant to UV radiation and moisture, shielding automotive components from damage and prolonging their lifespan. With its versatility, ease of fabrication, and eco-friendly profile, EVA foam is redefining the standards of automotive manufacturing, paving the way for innovative designs that cater to both aesthetic and functional demands.