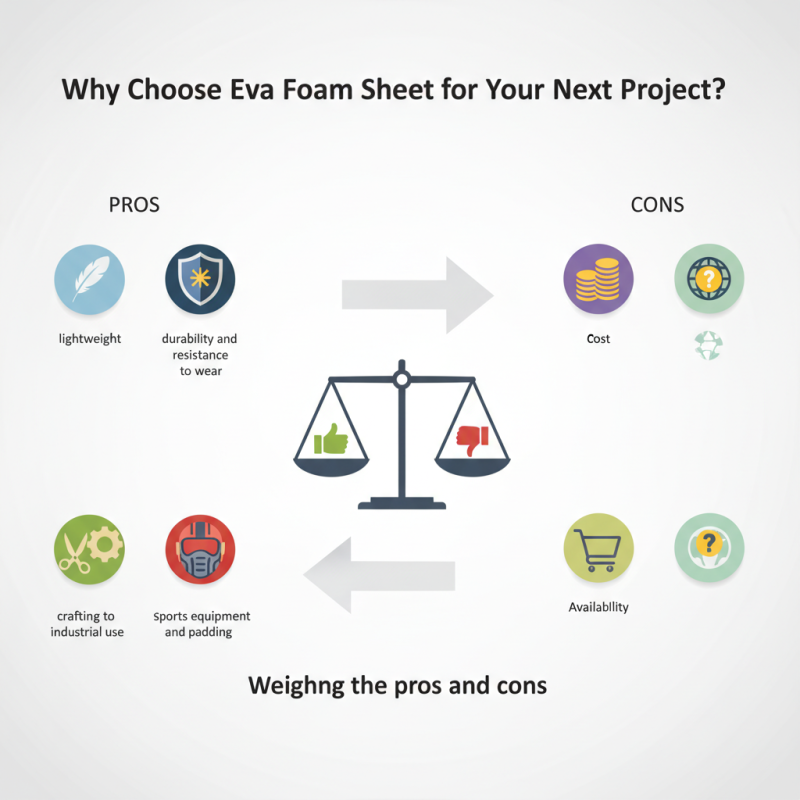

When planning your next project, consider the benefits of using Eva Foam Sheet. This versatile material stands out for its unique properties. Its lightweight nature makes it easy to handle and transport. Eva Foam Sheet is also known for its durability and resistance to wear.

This foam can be used in various applications, from crafting to industrial use. Its shock-absorbing qualities are particularly appealing. For instance, sports equipment and padding often rely on Eva Foam Sheet to enhance safety and comfort. However, not every project might benefit from it. You may need to evaluate your specific requirements carefully.

While Eva Foam Sheet offers many advantages, it's not always the perfect choice. Consider factors like cost and availability in your area. Reflecting on these aspects can lead to more informed decisions. Ultimately, weighing the pros and cons is crucial for achieving the best results in your project.

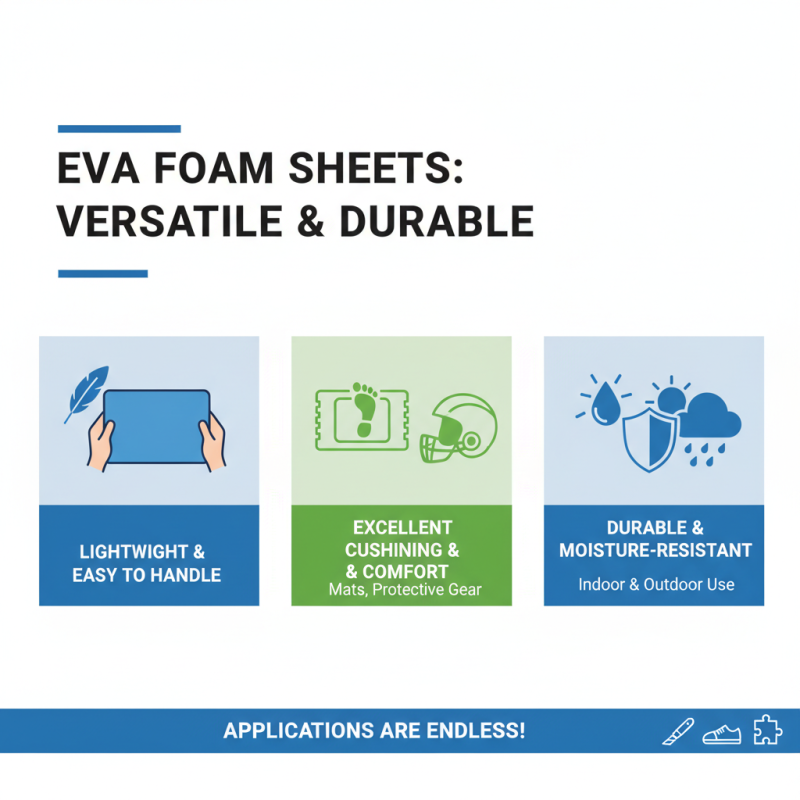

Eva foam sheet is versatile and widely used in various applications. Its lightweight nature makes it easy to handle, which is essential for many projects. With its excellent cushioning properties, it provides comfort in items like mats and protective gear. People often overlook its durability and resistance to moisture. This makes it suitable for indoor and outdoor use.

The flexibility of Eva foam allows for creativity in design. It can be cut, shaped, and colored as needed. Craft enthusiasts often use it for making costumes, props, and decorations. However, some may struggle with precision cutting. Practice makes perfect, but the initial attempts can lead to uneven edges or unwanted shapes. This can be frustrating, yet it fosters growth in crafting skills.

Furthermore, Eva foam is non-toxic, making it safe for children. This aspect is crucial for toys and play areas. However, not all grades are created equal. Some may lack the desired sturdiness. It's helpful to research and test different options before committing to a large purchase. Not every project will require the same thickness or density. Consider the specific needs and the intended use before making a choice.

EVA foam sheets are gaining popularity in various industries due to their exceptional properties. These sheets are lightweight yet durable, making them ideal for both indoor and outdoor projects. According to a report by Market Research Future, the global EVA foam market is expected to reach USD 3 billion by 2026, highlighting its growing importance.

One of the key advantages of EVA foam is its excellent cushioning ability. This property makes it suitable for applications, such as sports equipment and protective gear. Additionally, EVA foam is resistant to UV rays and moisture. This resistance can significantly extend the lifespan of products made from it. However, it’s not invulnerable. In extreme conditions, EVA can degrade faster than some alternatives, which is worth considering when planning your project.

Another compelling aspect is EVA foam's versatility. It can be easily molded and cut into different shapes. This flexibility allows for creative designs and solutions. Nonetheless, some users find it challenging to achieve precise cuts without the right tools. Proper preparation is vital. Without it, the final product may not meet expectations. Balancing cost and quality is essential. Sometimes, opting for lower-quality sheets can lead to wasted resources and effort later on.

| Property | Description |

|---|---|

| Lightweight | EVA foam sheets are significantly lighter than many other materials, making them easier to handle and transport. |

| Durability | They offer excellent resistance to wear and tear, ensuring longevity in various applications. |

| Water Resistance | EVA foam sheets are resistant to water, making them suitable for outdoor and damp environments. |

| Flexibility | They can be easily shaped and molded, allowing for creative design possibilities in various projects. |

| Impact Resistance | EVA foam absorbs shock effectively, making it ideal for protective applications. |

| Sound Insulation | The material offers good sound absorption properties, which can enhance comfort in residential and commercial spaces. |

| Eco-Friendly Options | Some EVA foam sheets are made from recycled materials, providing more sustainable project options. |

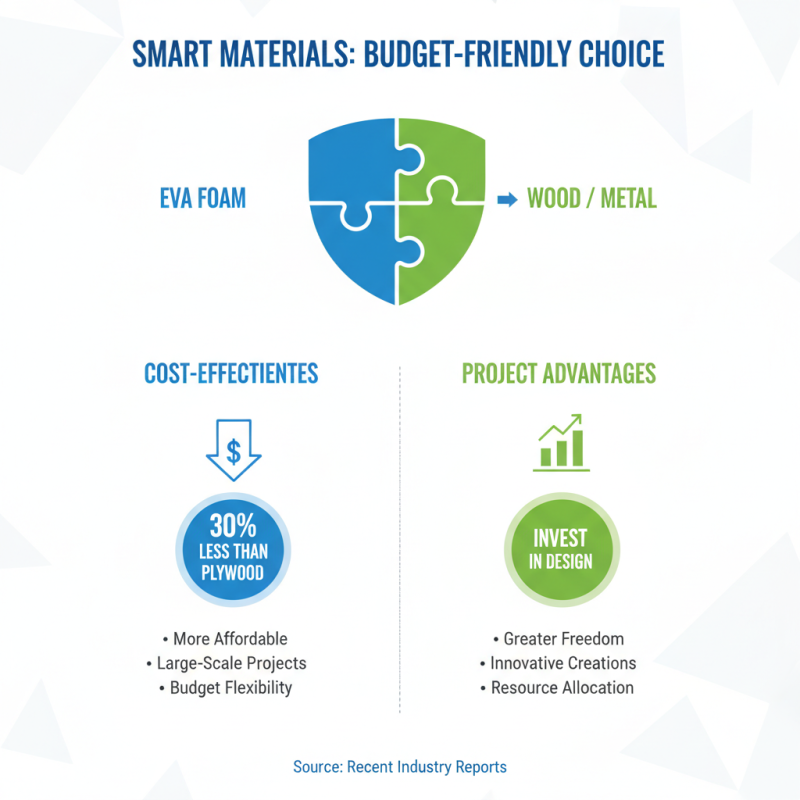

When considering materials for your next project, cost-effectiveness is a key factor. EVA foam sheets are often more affordable compared to traditional materials like wood or metal. According to recent industry reports, EVA foam costs about 30% less than plywood per square foot, making it an attractive option for large-scale projects. This cost advantage allows for more budget flexibility, empowering creators to invest in other aspects of their designs.

Moreover, EVA foam sheets offer durability without the high price tag. Industry data shows that EVA foam has a lifespan of over five years in typical usage conditions. In contrast, cheaper alternatives may degrade quickly, leading to additional long-term costs for replacements or repairs. While it is essential to assess the durability of materials, EVA foam often strikes a balance between price and performance.

However, it's crucial to acknowledge that not all projects may benefit from EVA foam's unique properties. For heavy-duty applications, its softness might limit functionality. In such cases, exploring hybrid options could provide a better solution. Balancing cost and performance sometimes requires compromises specific to your project's needs.

The environmental impact of materials we choose is crucial. EVA foam sheets are gaining attention for their sustainability. According to a recent report by the International Journal of Life Cycle Assessment, EVA foam has a lower carbon footprint compared to many traditional materials, with reductions of up to 30% in greenhouse gas emissions. This makes EVA a viable choice for eco-conscious designers.

EVA foam is recyclable. In fact, studies show that up to 95% of EVA products can be repurposed. This is significant, given that around 300 million tons of plastic are produced globally each year, leading to increasing pollution. However, challenges remain. Not all recycling facilities can process EVA foam. This creates a need for better systems and more widespread acceptance in recycling programs.

The production process of EVA foam sheets requires careful consideration. While manufacturing is less harmful, the use of additives remains a concern. Some additives can pose environmental risks. As users, we should demand transparency and better practices. With continuous innovations, the focus on sustainable practices will hopefully improve over time.

Eva foam sheets are incredibly versatile and have found applications in many industries. These sheets are lightweight and durable, making them perfect for everything from crafting to construction. In the automotive industry, Eva foam provides insulation and cushioning. It helps to absorb shock and reduce noise, enhancing comfort for passengers. In sports and fitness, Eva foam plays a crucial role. It is used in mats and protective gear, ensuring safety and comfort during activities.

When considering eva foam sheets for your project, think about your specific needs. Are you focusing on insulation, cushioning, or sound absorption? Different thicknesses and densities can affect performance. For crafting, choose a sheet that’s easy to cut and shape. For construction, sturdier options are essential.

**Tips:** Always test a small piece first. This helps gauge how it performs for your project. Evaluate the foam's flexibility and durability before committing. Sometimes the cheapest option may not meet your needs in the long run. Consider the environment too; some foams are more eco-friendly than others.